Table of Contents

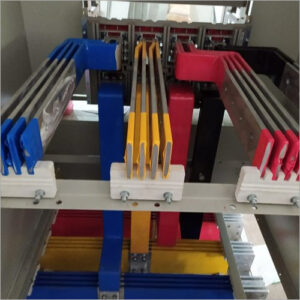

C-Fit Copper is the well-established business organization of Qatar that is specialized in manufacturing and exporting Copper Bus Bars of highly quality and precision. You will always find quality products with standard that is observed from all over the world. Our bus bars offer high conductivity and withstand tough usage as our skill in fabrication creates beautiful tools for the many industries out there. From power distribution to electrical grounding to several other areas, our portfolio provides solutions accordingly.

C-Fit Copper is a company that is innovative and customer centric, and has been keen on developing products that solve exact needs. Adopting state of the art technology and uncompromising quality assurance, it offers quality right from the manufacturing line, and consolidating its status as the leading supplier in industrial Qatar. Choose C-Fit Copper for the highest quality and performance of Copper Bus Bars.

Types in Copper Bus bars:

Flat Busbars in Qatar

Flat busbars can be described as metallic bars or strips that are in flat form and are commonly used as conductors in power systems mainly made from copper or aluminum. They are slim in structure so that they can transfer power effectively and can also be installed easily.

Hallow Busbars in Qatar

Hollow Copper bus bar is a cylindrical conductor with a central bore through it and provides a means for efficient power conduction while consuming lesser material and weight which makes it practically suitable for application in various electrical systems that require light, but strong conductors.

Insulated Busbars in Qatar

Insulated busbars are currents-carrying metallic strips with an insulating sheath surrounding the metallic part, which is usually made of such materials as PVC or epoxy to minimize the chances of a short circuit and maximize safety in power distributed systems due to the improved insulation capability.

Copper Bus Bars Specification

Bus bars usually use standardized dimensions keeping in mind optimal performance and fitting properly within the electrical system. The specifications which are provided include material composition, whether it is copper or aluminum as well as various grades of purity levels for conductivity. Besides, Copper bus bars as well are specified by dimensions in which the thickness, width, and length are designed for current carrying capacity and space limitations of the application. Surface finish, for corrosion resistance and electrical contact are also required to be specified such as tin plating or bare copper.

| Copper Bus Bar Specification | ||

|---|---|---|

| Dimension Details :- | Thickness 1 mm (min) 2 mm (min) 3 mm (min) 5 mm (min) 6 mm -50 mm | Width 10 mm – 50 mm 10 mm – 100 mm 10 mm – 150 mm 10 mm – 200 mm 10 mm – 250 mm |

| Specifications (ETP) :- | IS: 191, 613 & 1897, BS EN 13601:2002, ASTM B187 | |

| Cross section :- | upto 3000 mm² | |

| Standard :- | EN 13601: 2002, EN 13602: 2002 | |

| Conductivity :- | Above 97% IACS min in Half Hard Above 99.95% in annealed | |

| Purity :- | Copper – 99.9% | |

| Specifications (OFC) :- | Copper: 99.99%, O 2: < 10 ppm Copper: 99.90%, O 2: < 100 ppm | |

| Type :- | Rectangular, square and any corner radius, Full Round Edge | |

Features of Copper Bus Bars

- Excellent Conductivity: Copper is one of the best conductors of electricity hence makes electricity to flow with much ease without posing much resistance.

- Corrosion Resistance: Copper bus bars are less prone to corrosion and, as such, they’re long-lasting and efficient even when used under unfavorable conditions.

- High Thermal Conductivity: Copper bus bars offer better conductivity and lower resistance than conventional wiring, thereby minimizing heat build-up which enhances safety.

- Flexibility: The copper bus bars can be cost effectively formed or bent to fit particular design configurations typically associated with easy installation modifications.

- High Mechanical Strength: Copper bus bars also possess good mechanical characteristics and have reliable mechanical durability which is beneficial in application where such characteristics are required.

- Low Maintenance: Copper bus bars have a longer equipment life span since they are resistant to corrosion and need slight maintenance hence cutting down on downtime and expenses.

| Material E-copper F30 current load in A | Material E-AL current load in A | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| width x thickness mm | weight kg/ meter | AC up to 60 Hz bar | DC + AC up to 16 2/3 Hz bar | weight kg/meter | AC up to 60 Hz bar | DC + AC up to 16 2/3 Hz bar | ||||||

| uncoated | painted | uncoated | painted | uncoated | painted | uncoated | painted | |||||

| 40 | x | 3 | 1,070 | 366 | 435 | 367 | 436 | 320 | 285 | 346 | 285 | 346 |

| 25 | x | 5 | 1,115 | 327 | 384 | 327 | 384 | 340 | 255 | 305 | 255 | 305 |

| 30 | x | 5 | 1,340 | 379 | 447 | 380 | 448 | 410 | 295 | 356 | 296 | 356 |

| 20 | x | 10 | 1,780 | 427 | 497 | 428 | 499 | 540 | 331 | 393 | 331 | 393 |

| 40 | x | 5 | 1,780 | 482 | 573 | 484 | 576 | 540 | 376 | 456 | 376 | 457 |

| 50 | x | 5 | 2,230 | 583 | 697 | 588 | 703 | 680 | 455 | 556 | 456 | 558 |

| 30 | x | 10 | 2,670 | 573 | 676 | 579 | 683 | 810 | 445 | 536 | 447 | 538 |

| 60 | x | 5 | 2,670 | 688 | 826 | 696 | 836 | 810 | 533 | 655 | 536 | 658 |

| 40 | x | 10 | 3,560 | 715 | 850 | 728 | 865 | 1,080 | 557 | 677 | 561 | 682 |

| 80 | x | 5 | 3,560 | 885 | 1070 | 902 | 1090 | 1,080 | 688 | 851 | 694 | 858 |

| 50 | x | 10 | 4,450 | 852 | 1020 | 875 | 1050 | 1,350 | 667 | 815 | 674 | 824 |

| 100 | x | 5 | 4,450 | 1080 | 1300 | 1110 | 1340 | 1,350 | 846 | 1050 | 858 | 1060 |

| 60 | x | 10 | 5,340 | 985 | 1180 | 1020 | 1230 | 1,620 | 774 | 951 | 787 | 966 |

| 80 | x | 10 | 7,120 | 1240 | 1500 | 1310 | 1590 | 2,160 | 983 | 1220 | 1010 | 1250 |

| 100 | x | 10 | 8,900 | 1490 | 1810 | 1600 | 1940 | 2,700 | 1190 | 1480 | 1240 | 1540 |

| 120 | x | 10 | 10,680 | 1740 | 2110 | 1890 | 2300 | 3,240 | 1390 | 1730 | 1460 | 1830 |

| 160 | x | 10 | 14,240 | 2220 | 2700 | 2470 | 3010 | 4,320 | 1780 | 2220 | 1900 | 2380 |

| 200 | x | 10 | 17,800 | 2690 | 3290 | 3040 | 3720 | 5,400 | 2160 | 2710 | 2350 | 2960 |

| 12 | x | 2 | 210 | 108 | 123 | 108 | 123 | 60 | 84 | 97 | 84 | 97 |

| 15 | x | 2 | 270 | 128 | 148 | 128 | 148 | 80 | 100 | 118 | 100 | 118 |

| 20 | x | 2 | 360 | 162 | 189 | 162 | 189 | 110 | 127 | 150 | 127 | 150 |

| 15 | x | 3 | 400 | 162 | 187 | 162 | 187 | 120 | 126 | 148 | 126 | 148 |

| 20 | x | 3 | 530 | 204 | 237 | 204 | 237 | 160 | 159 | 188 | 159 | 188 |

| 25 | x | 3 | 670 | 245 | 287 | 245 | 287 | 200 | 190 | 228 | 191 | 228 |

| 30 | x | 3 | 800 | 285 | 337 | 286 | 337 | 240 | 222 | 267 | 222 | 268 |

| 20 | x | 5 | 890 | 274 | 319 | 274 | 320 | 270 | 214 | 254 | 214 | 254 |

Dimension Chart:

| Width * Height (W*H) | (W*H) sqmm | (W*H) sqmm |

|---|---|---|

| 25*05 | 60*05 | 100*08 |

| 30*05 | 60*08 | 100*10 |

| 30*08 | 60*10 | 100*12 |

| 35*05 | 70*05 | 110*08 |

| 35*08 | 70*08 | 110*10 |

| 40*05 | 70*10 | 110*12 |

| 40*08 | 70*12 | 120*08 |

| 40*10 | 80*05 | 120*10 |

| 50*05 | 80*08 | 120*12 |

| 50*08 | 80*10 | |

| 50*10 | 80*12 |

Advantages And Disadvantages

Advantages

- Efficient Conductivity: Copper is used because it provides a low resistance through which current flows without much interruption.

- Durable: As copper bus bars are less prone to corrosion their life expectancy is higher.

- Flexible: Customisable to various specifications and thus increasing installation adaptability.

- Dependable: Characterized by stability and mechanical strength for reliable performance.

- Effective: Specifically, low energy loss enhances the efficiency of the overall system.

Disadvantages

- Costly: It may also be more expensive in terms of initial cost than other material types such as aluminum.

- Heavy: A disadvantage of copper is that busbars are dense and therefore heavier than copper bus bars made of, for instance aluminum.

- Theft Risk: Copper is considered a valuable metal and is frequently stolen, which is why precautions must be taken.

- Thermal Expansion: Copper has a tendency to expand and contract and this can be a challenge in its engineering.

- Environmental Concerns: Both extraction and processing can be environmentally problematic, leading to sustainability concerns.