Table of Contents

At Copper Fitting Manufacturer, our specialty is to supply the best copper flanges with a quality assurance of supplying in Abu Dhabi. Its large number of products includes copper flanges displayed in different industries for their reliability and high performance. As a manufacture, dealer, and exporter, we aim at delivering products that are up to the standard of the international markets and beyond what our customer expect. Due to our long years of experience in the manufacturing and supplying of copper flange, Alliance can be your best partner for all your industrial requirements. Explore all our services and find out why we offer the best quality and service in the industry.

Copper Flanges manufacture, dealer, Exporter in Abu Dhabi :- Properties

Copper flanges which are well acclaimed for thermally as well as electrically are very vital items in several industrial uses. These flanges possess enhanced corrosion protection and are thus suitable for use under mainly extreme conditions. It is easy to machine and comes in close tolerance to fit the piping systems so that there are no leaks. Moreover, copper flanges also proved to be very strong and pressure and temperature resistant therefore can be relied on to last longer without fail. Their preventive and aesthetic features also increase their applicability to different industrial applications.

- Excellent Thermal and Electrical Conductivity: Copper flanges are very efficient in heat and electricity transfer hence they are used where energy transfer is of much importance. [it is necessary to have] this property to get the maximum performance for the systems that interact with high temperature or with electricity.

- Superior Corrosion Resistance: Copper flanges are made in a way that can endure the normal conditions of environment especially when exposed to humidity and other chemical products. This resistance to corrosion the life cycle of the flanges is enhanced and less replacements are required for tough industrial settings.

- Malleability and Machinability: Copper is in itself a material that can be easily worked on while in the state of a bar and due to this when it is offered to the piping system it fits perfectly since it has been machined to fit this particular system. This property makes it possible to design flanges with great precision and helps towards the delivery of a leak-proof connection.

- Durability and Strength: Copper flanges can take quite substantial loads of pressure and temperature changes and they do not deteriorate in the process. This makes them to be efficient and highly reliable during their operational activities hence improving efficiency of the system.

- Aesthetic Appeal and Low Maintenance: Copper flanges boasts an aesthetically pleasing look of the flanges itself that beautifies the industrial application. Also, since they require little attention when it comes to maintenance, they’re even more durable than their counterparts and so can be useful for form and function.

Copper Flanges manufacture, dealer, Exporter in Abu Dhabi :- Types

Copper flanges are available in standard types to meet the requirements of various industries and these are Slip-On flanges, Blind flanges, Weld Neck, Socket Weld, Threaded flanges, Orifice flanges, Lap Joint, and Raised Face flanges. Each one has its strength, like installation which is easy, or when subjected to pressure: it does not yield or even when used with the measurement systems. In Abu Dhabi as a manufacturer, dealer and exporter, we offer the complete copper flanges product line that offers facility to match a specific application perfectly in terms of accuracy and strength.

Weld Neck Flanges in Abu Dhabi

Weld Neck Flanges have a long neck that is a part of the pipe and is welded to the body of the flange; they are strong and able to withstand high pressure and temperature. Due to their design, they are suitable for use in application areas that require very firm connections.

Slip-on Flanges in Abu Dhabi

These flanges are intended to fit over the pipe and they are normally welded both internally and externally to give efficient sealing rings which ensure that there is no leakage. They are not very complicated to mount and are widely employed in several uses because of this feature alone.

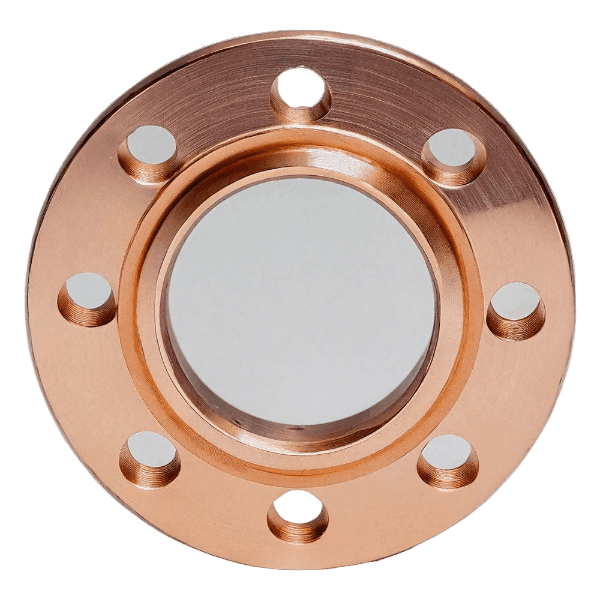

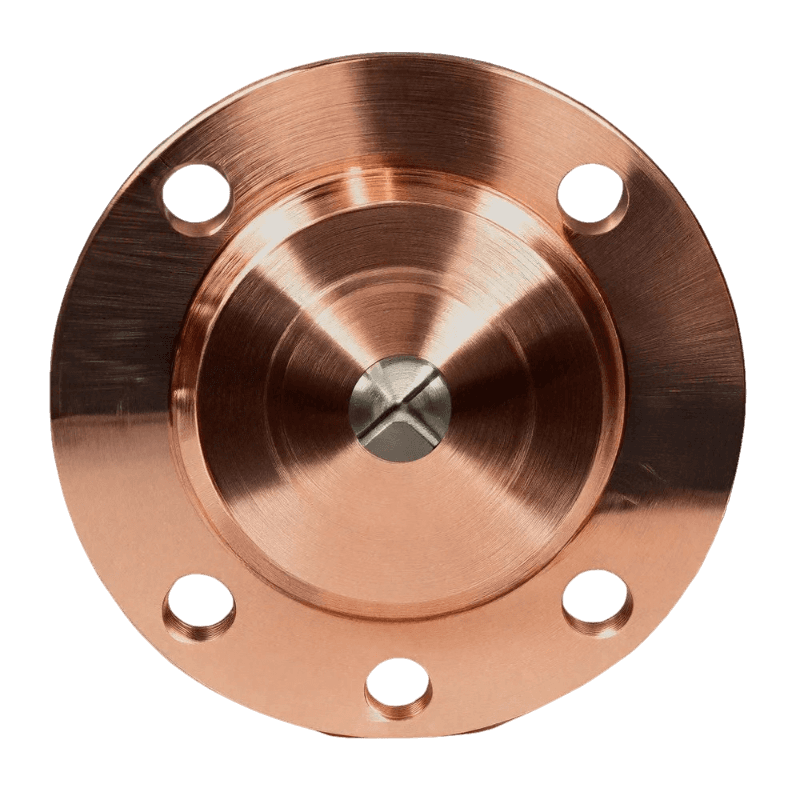

Blind Flanges in Abu Dhabi

Blind flanges are applied to seal off the end of a pipe line or vessel. Flanges are used for sealing chokes and form a leak tight surface to keep the system pressure intact and are most important. Blind flanges are available in various dimensions and classes to meet the specifications of the applications.

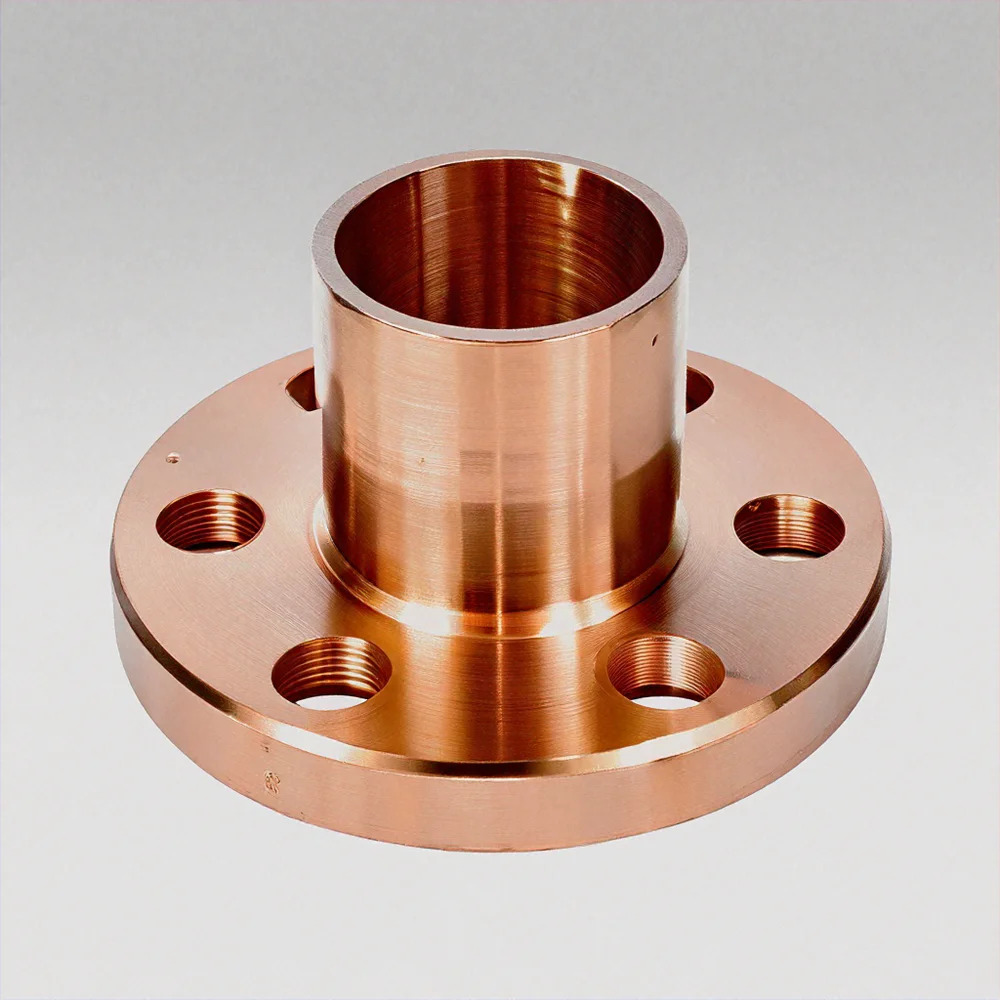

Socket Weld Flanges in Abu Dhabi

These flanges are meant for relatively small applications in terms of the pipe diameter and here the pipe is simply placed into the flange socket and then welded. Some of the most common features of this type of flange are great durability; therefore, most pressure applications use this type of flange.

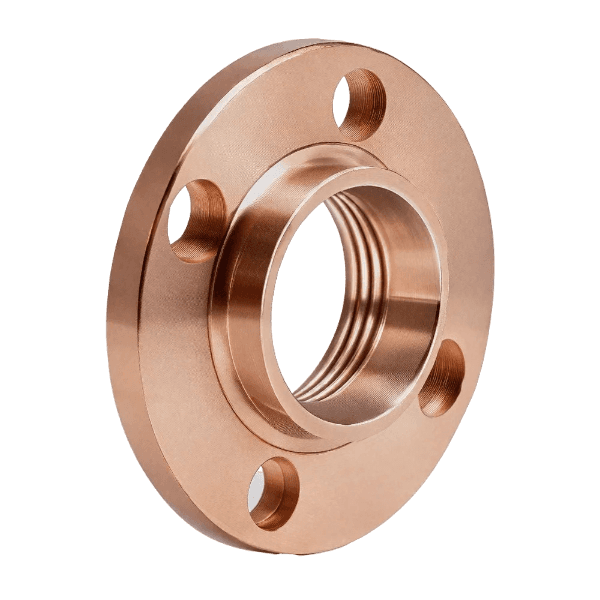

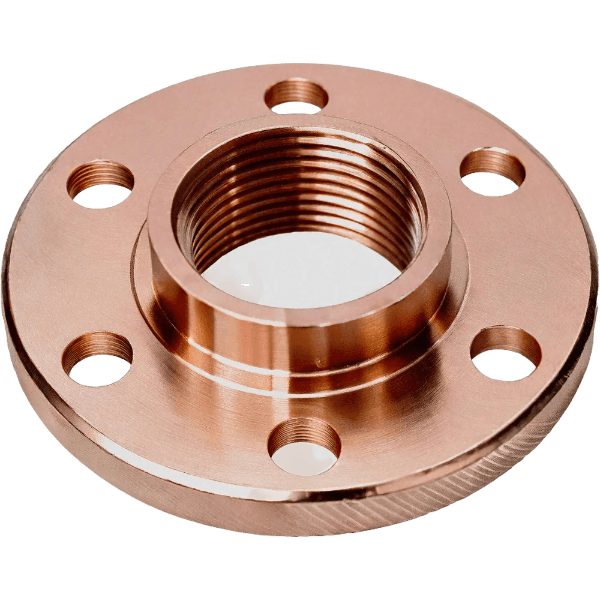

Threaded Flanges in Abu Dhabi

Terminations comprise threaded flanges which have internal threads on them to enable them to be screwed on to the pipe without necessitating welding. It is good for use where welding is not possible and is a quick way of making pipes connections.

Orifice Flanges in Abu Dhabi

Applicable for use in the measurement of flow of products in pipelines, this type of flanges is provided with a borehole to house the orifice plate. They customarily find application in systems of measuring and controlling the flow of fluids.

Lap Joint Flanges in Abu Dhabi

Lap joint flanges are common in conjunction with a lap joint stub end making it possible to disassemble and reassemble easily. These are used where used where there is high likelihood of having to practically maintain or inspect the drives frequently.

Raised Face Flanges in Abu Dhabi

Some of these flanges have a raised face around the bolt holes to give a better seal against the gasket. They are employed in several sectors and are suitable for use with conventional gasket materials.

Copper Flanges manufacture, dealer, Exporter in Abu Dhabi :- Size, Weight , Dimensions Tables

By so doing our copper flanges can be produced in different sizes hence meeting the different dimensions that is demanded in the market. The dimensions of the each flange put into design and the build of each flange is done in a way that meets the weight requirements and is in compliance with the international standards. Flanges are a universally well-liked sort, no matter if their utilised application will be high-pressure and something beyond – the tables which comprise the dimensions and the weight of all flange types include the necessary information for the certain job. A table showing size weight and dimensions of copper flanges is as follows please consult this table for exact copper flanges to suit your requirements.

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. of Hub Top | SO LTH | WN LTH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.5 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.5 | 1.05 | 0.56 | 2 |

| 1 | 4.25 | 0.5 | 2 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.5 | 4 | 0.62 | 3.5 | 1.7 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.9 | 0.81 | 2.38 |

| 2 | 6 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7 | 0.81 | 4.12 | 4 | 0.75 | 5.5 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.5 | 0.88 | 5 | 4 | 0.75 | 6 | 3.57 | 3.07 | 4.25 | 3.5 | 1.12 | 2.69 |

| 31⁄2 | 8.5 | 0.88 | 5.5 | 8 | 0.75 | 7 | 4.07 | 3.55 | 4.81 | 4 | 1.19 | 2.75 |

| 4 | 9 | 0.88 | 6.19 | 8 | 0.75 | 7.5 | 4.57 | 4.03 | 5.31 | 4.5 | 1.25 | 2.94 |

| 5 | 10 | 0.88 | 7.31 | 8 | 0.88 | 8.5 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11 | 0.94 | 8.5 | 8 | 0.88 | 9.5 | 6.72 | 6.07 | 7.56 | 6.63 | 1.5 | 3.44 |

| 8 | 13.5 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16 | 1.12 | 12.75 | 12 | 1 | 14.25 | 10.88 | 10.02 | 12 | 10.75 | 1.88 | 3.94 |

| 12 | 19 | 1.19 | 15 | 12 | 1 | 17 | 12.88 | 12 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14 | 2.19 | 4.94 |

| 16 | 23.5 | 1.38 | 18.5 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18 | 16 | 2.44 | 4.94 |

| 18 | 25 | 1.5 | 21 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18 | 2.62 | 5.44 |

| 20 | 27.5 | 1.62 | 23 | 20 | 1.25 | 25 | 20.2 | 19.25 | 22 | 20 | 2.81 | 5.62 |

| 22 | 29.5 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22 | 3.07 | 5.82 |

| 24 | 32 | 1.81 | 27.25 | 20 | 1.38 | 29.5 | 24.25 | 23.25 | 26.12 | 24 | 3.19 | 5.94 |

Use of Copper Flanges in Abu Dhabi

Copper flanges are widely used in Abu Dhabi in many industries because of the material’s high strength and opposition to corrosion. This is important especially in industrial applications where they are used in such applications as high pressure applications, chemical applications and heat transfer applications such as heat exchangers. As for multiple use, copper flanges beautify the systems of plumbing and of heating and ventilation with their installation and can be used for both practical and ornamental purposes.

Industrial Applications

- High-Pressure Systems: It is generally used in high pressure pipelines and systems because of its high tolerance to pressure and Series of its flanges. It affords safe, airtight connection; these are important in maintaining system coherence where conditions are challenging.

- Chemical Processing: Flanges made from copper are extremely resistant to corrosion and hence are useful in industries that use chemical reagents. Thanks to their robustness, the materials are guaranteed to operate for long durations and with minimal need for repairs in chemical processing conditions.

- Heat Exchangers: Copper is more efficient in thermal conductivity thus it is widely used in cases of heat exchangers. Copper flanges also plays crucial role in enhancement of heat flow and assures that the systems power remains constant in many industrial procedures.

General Applications

- Plumbing Systems: Copper flanges are preferred for use in the residential as well as commercial buildings because of their durability and flexibility in terms of installation. They provide secure connections and are most often anti-corrosive to improve on the plumbing system’s framework.

- HVAC Systems: Copper flanges are applied in HVAC systems where they serve as connectors to unite system segment while offering reliability. The temperature changes endurance, as well as the capacity to provide a sealed system, are essential qualities in operating the systems.

- Decorative Applications: Copper flanges are also used in decorative purposes as they have a rather attractive appearance. They are commonly employed in the construction of architectural items and design forms where both use and beauty are needed.