Table of Contents

C-Fit Copper is one of the prestigious company established in Saudi Arabia which is specialized in manufacturing and exporting copper bus bars. C-Fit Copper offer high quality and dependable bus bars specifically designed to answer the electrical demands for various sectors. Being made of high-grade copper, the electrical wiring is capable of providing a optimum power distribution and negligible energy wastage.

Having modern sophisticated factories, our products have high quality that meet standard levels in terms of accuracy and quality. Unlike other companies who offer products and services in the market, C-Fit Copper is realising these core values through costumer focus, quality, and effective customer service support with the ability to provide specialty products according to customers needs. As a supplier of quality materials for various projects in Saudi Arabia and around the world, the clients can rely on C-Fit Copper for durable copper bus bars.

Types in Copper Busbars:

Copper bus bar comes in different varieties: there are the flat bus bars, solid bus bar, laminated, and flexible bus bars; these are designed to meet specific electrical distribution requirements. Such types guarantee effective conducting, minimized power loss, and flexibility in power networks and manufacturing facilities.

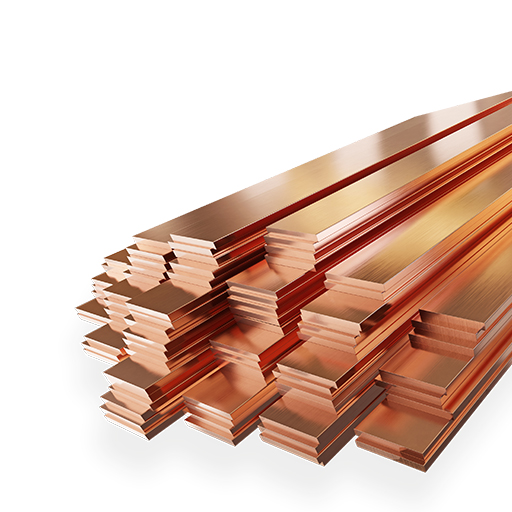

Flat Copper Bus bars in Saudi Arabia

Flat busbars are conductive strips of rectangular cross-section used for power distribution in electrical equipment. It can easily be installed and connected because of their low profile, and uniform shape which enhances space utilization in different settings.

Hallow Copper Bus bars in Saudi Arabia

There is a mechanical advantage in Hallow busbars because they are made of tubular steel that gives additional strength and conductivity for power distribution. One of its benefits is that their body is built of the hollow, thus enabling coolness for used in current applications.

Insulated Copper Bus bars in Saudi Arabia

An insulated busbar is a single or multiple conductor running in complete or partial circuit that has an insulation around it for increased safety against electric shocks. They also ensure that there is adequate flow of power and also issues to do with short circuits are well dealt with.

Copper Bus Bars Specification:

Bus bars usually use standardized dimensions keeping in mind optimal performance and fitting properly within the electrical system. The specifications which are provided include material composition, whether it is copper or aluminum as well as various grades of purity levels for conductivity. Besides, bus bars as well are specified by dimensions in which the thickness, width, and length are designed for current carrying capacity and space limitations of the application. Surface finish, for corrosion resistance and electrical contact are also required to be specified such as tin plating or bare copper.

| Copper Bus Bar Specification | ||

|---|---|---|

| Dimension Details :- | Thickness 1 mm (min) 2 mm (min) 3 mm (min) 5 mm (min) 6 mm -50 mm | Width 10 mm – 50 mm 10 mm – 100 mm 10 mm – 150 mm 10 mm – 200 mm 10 mm – 250 mm |

| Specifications (ETP) :- | IS: 191, 613 & 1897, BS EN 13601:2002, ASTM B187 | |

| Cross section :- | upto 3000 mm² | |

| Standard :- | EN 13601: 2002, EN 13602: 2002 | |

| Conductivity :- | Above 97% IACS min in Half Hard Above 99.95% in annealed | |

| Purity :- | Copper – 99.9% | |

| Specifications (OFC) :- | Copper: 99.99%, O 2: < 10 ppm Copper: 99.90%, O 2: < 100 ppm | |

| Type :- | Rectangular, square and any corner radius, Full Round Edge | |

Features of Copper Bus Bars

- Excellent Thermal Conductivity: Copper bus bars act as good heat sinks for heat produced during the operation to avoid melting and consequently enhancing system integrity.

- Corrosion Resistance: Copper is resistant to corrosion and has a documented long life and durability even in some of the most severe conditions.

- Malleability and Ductility: This was due to the flexibility offered by copper bus bar manufacturer that can be easily formed and bent to conform to intricate designs, thus implementing the section.

- High Mechanical Strength: Copper bus bars become mechanically stable and can resist mechanical forces, stresses and other forms of vibrations.

- Low Maintenance: Copper bus bar Manufacturer are also long lasting structures whose life is further enhanced by their ability to withstand corrosion hence leading to low maintenance costs and unscheduled station downtimes.

- Compatibility: Copper bus bars have good compatibility with insulation material and connection configuration, making it feasible to be adopted in multiple systems.

Copper Bus Bars Weight, Size and Dimension Chart, busbar size calculation:

C-Fit Copper is the manufacturer of bus bars of copper which are made to the exact weight, size and dimension charts to ease calculation of busbar size. C-Fit Copper data chart enables engineers to choose the appropriate copper busbar used in electrical, industrial and power distribution uses.

| Material E-copper F30 current load in A | Material E-AL current load in A | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| width x thickness mm | weight kg/ meter | AC up to 60 Hz bar | DC + AC up to 16 2/3 Hz bar | weight kg/meter | AC up to 60 Hz bar | DC + AC up to 16 2/3 Hz bar | ||||||

| uncoated | painted | uncoated | painted | uncoated | painted | uncoated | painted | |||||

| 40 | x | 3 | 1,070 | 366 | 435 | 367 | 436 | 320 | 285 | 346 | 285 | 346 |

| 25 | x | 5 | 1,115 | 327 | 384 | 327 | 384 | 340 | 255 | 305 | 255 | 305 |

| 30 | x | 5 | 1,340 | 379 | 447 | 380 | 448 | 410 | 295 | 356 | 296 | 356 |

| 20 | x | 10 | 1,780 | 427 | 497 | 428 | 499 | 540 | 331 | 393 | 331 | 393 |

| 40 | x | 5 | 1,780 | 482 | 573 | 484 | 576 | 540 | 376 | 456 | 376 | 457 |

| 50 | x | 5 | 2,230 | 583 | 697 | 588 | 703 | 680 | 455 | 556 | 456 | 558 |

| 30 | x | 10 | 2,670 | 573 | 676 | 579 | 683 | 810 | 445 | 536 | 447 | 538 |

| 60 | x | 5 | 2,670 | 688 | 826 | 696 | 836 | 810 | 533 | 655 | 536 | 658 |

| 40 | x | 10 | 3,560 | 715 | 850 | 728 | 865 | 1,080 | 557 | 677 | 561 | 682 |

| 80 | x | 5 | 3,560 | 885 | 1070 | 902 | 1090 | 1,080 | 688 | 851 | 694 | 858 |

| 50 | x | 10 | 4,450 | 852 | 1020 | 875 | 1050 | 1,350 | 667 | 815 | 674 | 824 |

| 100 | x | 5 | 4,450 | 1080 | 1300 | 1110 | 1340 | 1,350 | 846 | 1050 | 858 | 1060 |

| 60 | x | 10 | 5,340 | 985 | 1180 | 1020 | 1230 | 1,620 | 774 | 951 | 787 | 966 |

| 80 | x | 10 | 7,120 | 1240 | 1500 | 1310 | 1590 | 2,160 | 983 | 1220 | 1010 | 1250 |

| 100 | x | 10 | 8,900 | 1490 | 1810 | 1600 | 1940 | 2,700 | 1190 | 1480 | 1240 | 1540 |

| 120 | x | 10 | 10,680 | 1740 | 2110 | 1890 | 2300 | 3,240 | 1390 | 1730 | 1460 | 1830 |

| 160 | x | 10 | 14,240 | 2220 | 2700 | 2470 | 3010 | 4,320 | 1780 | 2220 | 1900 | 2380 |

| 200 | x | 10 | 17,800 | 2690 | 3290 | 3040 | 3720 | 5,400 | 2160 | 2710 | 2350 | 2960 |

| 12 | x | 2 | 210 | 108 | 123 | 108 | 123 | 60 | 84 | 97 | 84 | 97 |

| 15 | x | 2 | 270 | 128 | 148 | 128 | 148 | 80 | 100 | 118 | 100 | 118 |

| 20 | x | 2 | 360 | 162 | 189 | 162 | 189 | 110 | 127 | 150 | 127 | 150 |

| 15 | x | 3 | 400 | 162 | 187 | 162 | 187 | 120 | 126 | 148 | 126 | 148 |

| 20 | x | 3 | 530 | 204 | 237 | 204 | 237 | 160 | 159 | 188 | 159 | 188 |

| 25 | x | 3 | 670 | 245 | 287 | 245 | 287 | 200 | 190 | 228 | 191 | 228 |

| 30 | x | 3 | 800 | 285 | 337 | 286 | 337 | 240 | 222 | 267 | 222 | 268 |

| 20 | x | 5 | 890 | 274 | 319 | 274 | 320 | 270 | 214 | 254 | 214 | 254 |

Copper Bus Bars Dimension and Size Chart:

| Copper Bus Bars Width * Height (W*H) | (W*H) sqmm | (W*H) sqmm |

|---|---|---|

| 25*05 | 60*05 | 100*08 |

| 30*05 | 60*08 | 100*10 |

| 30*08 | 60*10 | 100*12 |

| 35*05 | 70*05 | 110*08 |

| 35*08 | 70*08 | 110*10 |

| 40*05 | 70*10 | 110*12 |

| 40*08 | 70*12 | 120*08 |

| 40*10 | 80*05 | 120*10 |

| 50*05 | 80*08 | 120*12 |

| 50*08 | 80*10 | |

| 50*10 | 80*12 |

Copper Bus Bars Advantages

Copper Bus Bars Advantages

- Low electrical resistance guarantees the effective transfer of energy.

- High thermal conductivity is beneficial when heat must be removed quickly.

- High corrosion protection thus guarantees permanent service.

- Flexibility is easy to bend and mould to fit a desired shape and size.

- Environmentally friendly since it can be recycled and is made of sustainable materials.