Table of Contents

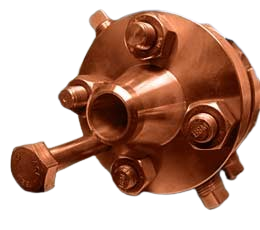

Here at Copper Fitting Manufacturer we deal in manufacturing and exporting of copper flanges for the Israel market. As a manufacturer, dealer and exporter of copper products, we assure to provide the best quality and highly accurate copper flanges to cater the needs of the different industries. Our products are made with distinctive quality and the manufacturing process involves a strict quality control which makes our products durable and reliable. We understand that some of our clients need tailored services while others need off-the-shelf products so, our team champions efficiency in service delivery as well as timely shipment within Israel. Get quality Copper flange from us for your business purpose and other requirements for a cost-effective price.

Copper Flanges manufacture, dealer, Exporter in Israel :- Properties

Based on the present research, copper flanges are unique parts used with high performance in several industries. These flanges are applied wherever pipes are required in the needs of plumbing, electrical, or even in heating ventilation and air conditioning where the expectation is to afford the best performances. They provide great features such as corrosion protection, thermal and electrical conductivity making copper flanges among the most popular by engineers and manufacturers. Its flexibility and beauty of appearance make them all the more useful for their practical uses as well as the looks.

- Corrosion Resistance: Flanges of copper offer enhanced resistance to corrosion; they are very useful where environments are rather aggressive – thus, they can be used in plumbing, marine, and chemical processing markets. This property makes sure that the flanges have a good look that will last for a long time and will not affect by the chemicals or saline solutions.

- Thermal Conductivity: Copper offers the best thermal properties that enable efficient heat transfer making these flanges suitable for HVAC applications and other related units such as heat exchangers and refrigeration. This also increases conductivity resulting to quick and efficient change in temperature of the circuits, which is extremely important in applications where cooling is mandatory.

- Malleability and Ductility: Copper flanges have excellent ductility and can be bent and shaped easily without the strength being compromised hence it is easy to manufacture the flanges with high accuracy of the shape required. They also allow for flexibility during the fabrication process so that they can fit certain design conditions thus they are suitable for various industrial uses.

- Electrical Conductivity: These flanges are also suitable for electrical work since copper is a conductor of electricity hence offering strong and secure connections. A high electrical conductivity reduces energy losses occurring in circuits and grounding in order to provide an efficient means of energy transmission.

- Durability: Copper flanges have the ability of lasting longer especially when used under pressures and high temperatures, this makes them to have a longer working cycle. Due to this they are suitable for applications where mechanical properties and durability are of major importance.

- Aesthetic Appeal: The raw appearance of copper gives installations a sophisticated feel and due to this reason, the material is widely used in architecture and ornamental features. Copper acquires a charming appearance over time forming a cover that can also act as barrier for various aspects of nature.

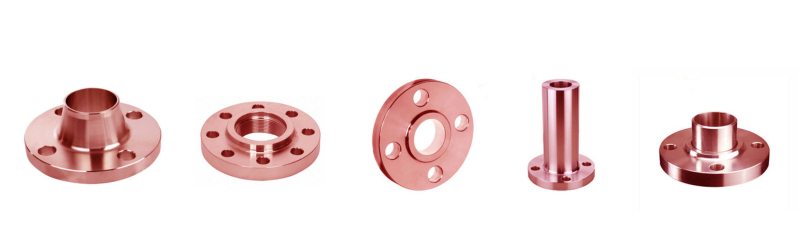

Copper Flanges manufacture, dealer, Exporter in Israel :- Types

Within copper flanges the types available are more diverse and are able to meet many of the industry demands. All these flange types are developed to meet certain requirements with the goal of providing your piping systems with not only protection, but efficiency as well. Knowing the variety of copper flange will greatly assist the user in selecting the proper one to utilize such as pressure applications, installation, and maintenance. Now let’s focus on the different subtypes of copper flanges and discuss the differences between them.

Copper Weld Neck Flanges in Israel

This type of Copper flanges possesses a number of design benefits, namely the long tapered hub which leads from the flange face to the pipe or fitting and which is designed to decrease stress concentration at the base of the flange. Due to such a design they are suitable for high pressure and high temperature applications where they are required to offer high strength. Being able to perform in critical conditions they provide a leak proof joint suitable for applications in oil and gas, chemical processing and power generation to name a few.

Copper Slip-On Flanges in Israel

A slip-on Copper flanges are commonly used because are very easy to install; the flange is slid over the pipe and both sides are welded. These flanges are best expressed for use in low pressure applications whereby the velocity of the fluid is predetermined and there is minimal chance of leakage. They are relatively cheap as opposed to something such as bolting and offer a reliable solution for systems that aren’t dismantled often.

Copper Blind Flanges in Israel

Female Copper flanges comprise of two pieces and do not have a hole while the blind flanges are equally special because they also have no through-hole hence suitable for closing the end of piping systems. They are crucial in creating pressure test, maintenance or expansion divides on different portions of the system. Thus, blind flanges complete the stoppage of the flow, and hence hold the integrity of the system In order to provide the safe operation of the system.

Copper Socket Weld Flanges in Israel

Also used in application where pipe sizes are comparatively small, socket weld flanges have a recess known as a socket which contain the pipe before welding. This results in optimization of the bore and establishment of a good and stable connection. These flanges are best suited to high pressure systems where Pip’s internal diameter has to be free from obstruction for the smooth flow of the fluids. Its design reduces leakage possibilities and makes them appropriate for use in petrochemical and power production sectors.

Copper Threaded Flanges in Israel

Screwed Copper flanges or threaded flanges are manufactured to be threaded and screwed on pipes having external threads on them. This feature renders them suitable for use where welding is not possible like areas with presence of flammable gases and or liquids. Consequently, threaded flanges can only be effective where pressure and temperature are low; they provide a good sealing means for small diameter pipe connections where they can be screwed together as in industries such as water treatment and plumbing.

Copper Lap Joint Flanges in Israel

Lap joint Copper flanges are typically used in connection with a stub end; they are particularly advisable for use in systems which are regularly taken apart for inspection, for cleaning or for maintenance. The flange is not attached to the pipe, and instead is bolted onto the stub end so it can swivel in order to help facilitate an easier alignment between the two parts when the system is being assembled. That is why lap joint flanges are applicable in low pressure conditions where easy access to the equipment and simple methods of its disassembling are required, for instance in food industry and pharmaceutics.

Copper Orifice Flanges in Israel

Orifice flanges are paired with orifice plates as the means of measuring the flow rate of some fluids in the system. These flanges are provided with extra tapped holes in order to facilitate the installation of pressure taps for metering instruments. Orifice flanges are used where a wide range of accuracy is imperative in the flow measured, like in the oil & gas industry, chemical industry and water and wastewater requirements. Their design enables measurement of the kind of flow and effectiveness of the system to make sure that in the end they deliver the best.

Copper Flanges manufacture, dealer, Exporter in Israel :-Size, Weight , Dimensions Tables

One thing that may interest you when choosing copper flanges is the size, weight and the dimensions that is required of it. The correct size and dimension of the right flange also play an important role in the overall design of the piping system and it will provide secure leak proof connection. It is also important to know the weight of the flanges, since it makes up part of the structure and needs to be maneuvered into place. Here are more elaborate tables that outlines the standard copper flange sizes and weight and dimensions and below is some of the copper flange types.

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. of Hub Top | SO LTH | WN LTH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.5 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.5 | 1.05 | 0.56 | 2 |

| 1 | 4.25 | 0.5 | 2 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.5 | 4 | 0.62 | 3.5 | 1.7 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.9 | 0.81 | 2.38 |

| 2 | 6 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7 | 0.81 | 4.12 | 4 | 0.75 | 5.5 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.5 | 0.88 | 5 | 4 | 0.75 | 6 | 3.57 | 3.07 | 4.25 | 3.5 | 1.12 | 2.69 |

| 31⁄2 | 8.5 | 0.88 | 5.5 | 8 | 0.75 | 7 | 4.07 | 3.55 | 4.81 | 4 | 1.19 | 2.75 |

| 4 | 9 | 0.88 | 6.19 | 8 | 0.75 | 7.5 | 4.57 | 4.03 | 5.31 | 4.5 | 1.25 | 2.94 |

| 5 | 10 | 0.88 | 7.31 | 8 | 0.88 | 8.5 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11 | 0.94 | 8.5 | 8 | 0.88 | 9.5 | 6.72 | 6.07 | 7.56 | 6.63 | 1.5 | 3.44 |

| 8 | 13.5 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16 | 1.12 | 12.75 | 12 | 1 | 14.25 | 10.88 | 10.02 | 12 | 10.75 | 1.88 | 3.94 |

| 12 | 19 | 1.19 | 15 | 12 | 1 | 17 | 12.88 | 12 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14 | 2.19 | 4.94 |

| 16 | 23.5 | 1.38 | 18.5 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18 | 16 | 2.44 | 4.94 |

| 18 | 25 | 1.5 | 21 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18 | 2.62 | 5.44 |

| 20 | 27.5 | 1.62 | 23 | 20 | 1.25 | 25 | 20.2 | 19.25 | 22 | 20 | 2.81 | 5.62 |

| 22 | 29.5 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22 | 3.07 | 5.82 |

| 24 | 32 | 1.81 | 27.25 | 20 | 1.38 | 29.5 | 24.25 | 23.25 | 26.12 | 24 | 3.19 | 5.94 |