Table of Contents

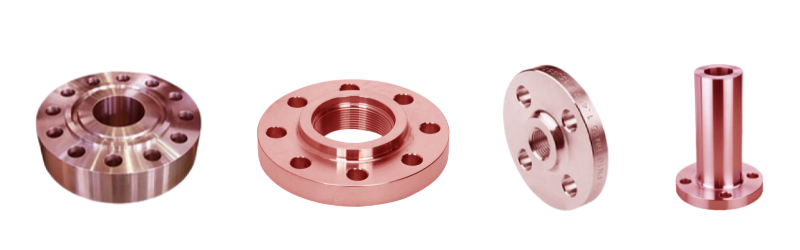

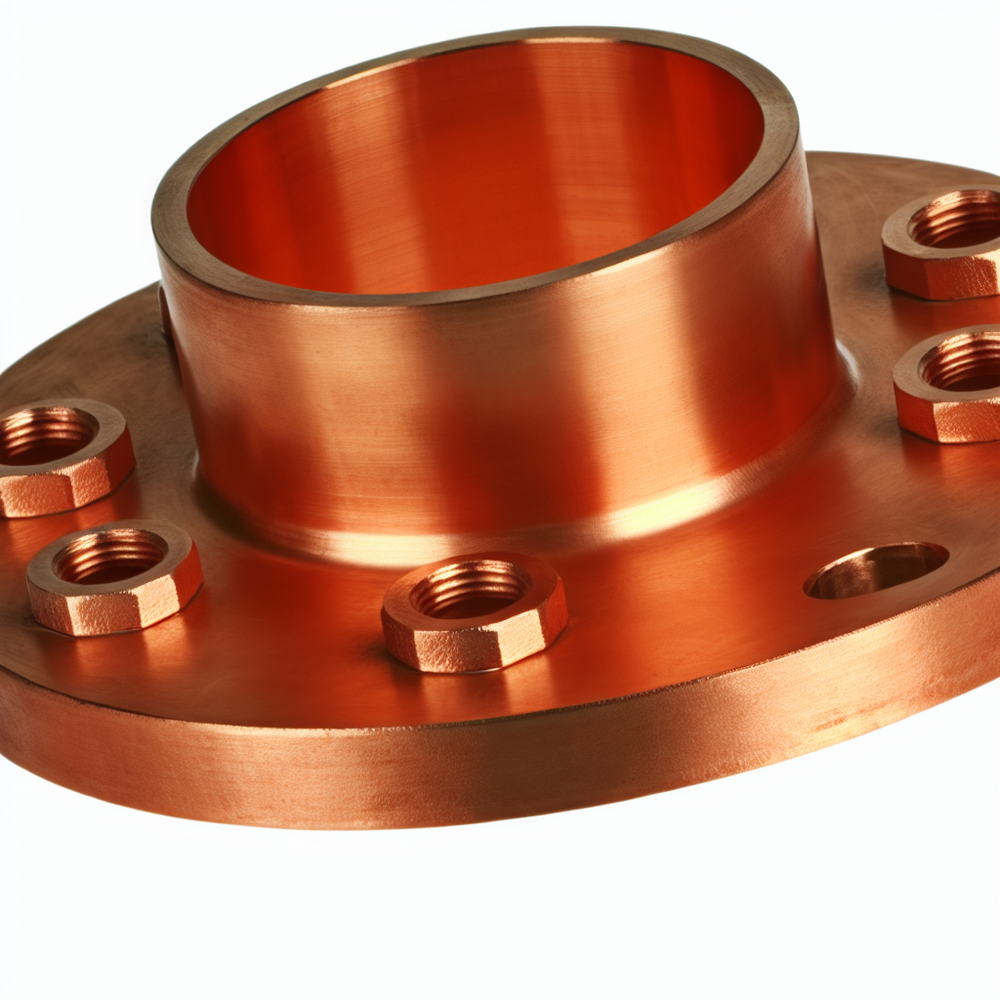

Beside presenting our assorted copper flanges we are proud to announce that we are now serving the Maldives. Our main goal is to offer original equipment manufacturer, dealer and exporter in offering high quality products to the international market. Our copper flanges have a great level of imperviousness to corrosive substances, well defined mechanical characteristics and accurate dimensions and can be utilized in different industries. Our services are very dependable and we value our Maldivian clients by offering them services that will suit their needs. We assure you with our expertise and experience to offer the best copper flanges suitable for your projects.

Copper Flanges Manufacture, Dealer and Exporter in Maldives : Properties

The Maldivian copper flanges are well known for their superior qualities hence they are used in several fields of industries. These flanges provide enhanced protection from corrosion, heat and electricity conduction as well as high sturdiness that make it useful for any environment. Their effectiveness and the possibility of easy creation makes them even more favorable to use in various purposes, including plumbing and electrical work.

- Corrosion Resistance: Copper flange is very resistant to corrosion and this working more efficaciously in the salty and humid environment which is familiar in the Maldives. This resistance also makes it possible to achieve a long life span which eliminates frequent maintenance and possible early failure especially in marine and coastal premises.

- Thermal Conductivity: Copper flanges possess good thermal conductivity which means that they are suitable in applications where heat transfer is important such as HVAC systems. This property makes it possible to get the best outputs with less or without energy consumption especially in homes or industries.

- Electrical Conductivity: That is why these flanges are suited for electrical systems, grounding and any other application where copper’s high conductivity is an advantage. This property aids in reduction of energy losses, safety and reliability of the electrical installation.

- Durability: Copper flanges are sturdy ones and are designed to withstand pressure and heat and thus retains its shape. This durability makes them ideal for applications that require a lot of force, as this makes them serve their purpose for quite a long period of time and rarely wears out.

- Ease of Fabrication: Copper is easily fabricated, particularly for fabrication of flanges; this makes it possible for one to design the flanges to suit a particular project. This ease of fabrication also makes installation a less complex process and hence makes copper flanges a versatile version that can be fit into many industries.

- Eco-Friendly: The demand for copper is safe for sustainable development as copper as a material is almost 100% recyclable. Selecting copper flanges are environmentally sensitive, thus the desire of every country to reduce emission while conserving resources.

Copper Flanges Manufacture, Dealer and Exporter in Maldives : - Types

Copper flanges are available in various differences with each being constructed to offer specific functionality in different industrial and plumbing applications. Such flanges as slip-on, weld neck, blind, and other special flanges are among the important ones as they provide particular benefits concerning their usage, wear-resistant properties, and fitting. Knowledge of the variety is necessary to choose a flanged item for the work being done so that it will connect efficiently with the pipe.

Copper Slip-On Flanges in Maldives

Slip-on flanges are to be slipped over the pipe and then welded to the pipe or structure as the case may be. Due to this design they are easy to install and perfect for usage where low pressure is called for and frequent connections required. Due to their features like being cheap, they can suit in many different areas of activity.

Copper Weld Neck Flanges in Maldives

Weld neck flanges are shaped by a long tapering hub that gives the required strength when welding it to the pipe. The two part design also helps reduce stress concentrations and are ideal for pressure vessels and service critical or severe duty applications.

Copper Blind Flanges in Maldives

Blind flanges are mainly used where the extremity of a pipeline is closed in order to stop the passage of a fluid or gas. Pressure testing and maintenance is achieved through them and it provides an access door when required for pressure testing avoiding the cutting and dismantling of pipes across the system.

Copper Socket Weld Flanges in Maldives

Socket weld flanges are used in pipe systems with small diameter but high pressures. The pipe is fitted into the flange’s recess and then welded and this gives a good sealing interface. It is particularly important for the systems with specific requirements for alignment and the tight fit between the components.

Copper Lap Joint Flanges in Maldives

Lap joint flanges are particularly utilized together with the stub end so that it can be assembled and dismantled quite easily. They are suitable for the systems which have to be dismantled often for inspection or for the maintenance purposes as they provide quick assembly and easy alignment that does not necessarily involve welding.

Copper Threaded Flanges in Maldives

Internal threaded flanges have a threaded internal bore allowing it to be screwed onto the pipe and thus not requiring welding. They are therefore well suited for circuits in low pressure situations or where welding is not possible because of the convenience of use and security and the easy lock and release system which can always be adjusted or removed if the need arises.

Copper Flanges Manufacture, Dealer and Exporter in Maldives :- Size, Weight And Dimensions Tables

Basically, size, weight and dimensions of copper flanges should be well understood to match with your existing piping system. All these factors have a cut on the flanges performance especially the pressure it can contain, the seal that it offers during usage and the ease of installation. It should be noted that the dimensions and weights are critical to maintaining the correct integrity of a system and its ability to make a tight seal. Actual and compatible dimensions not only enhance the performance of installations but also the durability and safety of it as well.

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. of Hub Top | SO LTH | WN LTH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.5 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.5 | 1.05 | 0.56 | 2 |

| 1 | 4.25 | 0.5 | 2 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.5 | 4 | 0.62 | 3.5 | 1.7 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.9 | 0.81 | 2.38 |

| 2 | 6 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7 | 0.81 | 4.12 | 4 | 0.75 | 5.5 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.5 | 0.88 | 5 | 4 | 0.75 | 6 | 3.57 | 3.07 | 4.25 | 3.5 | 1.12 | 2.69 |

| 31⁄2 | 8.5 | 0.88 | 5.5 | 8 | 0.75 | 7 | 4.07 | 3.55 | 4.81 | 4 | 1.19 | 2.75 |

| 4 | 9 | 0.88 | 6.19 | 8 | 0.75 | 7.5 | 4.57 | 4.03 | 5.31 | 4.5 | 1.25 | 2.94 |

| 5 | 10 | 0.88 | 7.31 | 8 | 0.88 | 8.5 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11 | 0.94 | 8.5 | 8 | 0.88 | 9.5 | 6.72 | 6.07 | 7.56 | 6.63 | 1.5 | 3.44 |

| 8 | 13.5 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16 | 1.12 | 12.75 | 12 | 1 | 14.25 | 10.88 | 10.02 | 12 | 10.75 | 1.88 | 3.94 |

| 12 | 19 | 1.19 | 15 | 12 | 1 | 17 | 12.88 | 12 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14 | 2.19 | 4.94 |

| 16 | 23.5 | 1.38 | 18.5 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18 | 16 | 2.44 | 4.94 |

| 18 | 25 | 1.5 | 21 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18 | 2.62 | 5.44 |

| 20 | 27.5 | 1.62 | 23 | 20 | 1.25 | 25 | 20.2 | 19.25 | 22 | 20 | 2.81 | 5.62 |

| 22 | 29.5 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22 | 3.07 | 5.82 |

| 24 | 32 | 1.81 | 27.25 | 20 | 1.38 | 29.5 | 24.25 | 23.25 | 26.12 | 24 | 3.19 | 5.94 |

Copper Flanges Manufacture, Dealer and Exporter in Maldives :- Uses

Industrial Applications

- HVAC Systems: Copper flanges find usage in a variety of heating, ventilation and air conditioning (HVAC) systems owing to their high thermal conductivity and because of the material’s ability to withstand high wear and tear.

- Marine and Offshore Engineering : From the corrosion resistance point of view, copper flanges are the most suitable for marine and offshore engineering applications where flanges are exposed to harsh and salty environment for longer durations to give optimum performance.

- Power Generation: Copper flanges are used in piping systems of power plants with the purpose of conveying high pressures steam and fluids. The strength and thermal conduction properties result into efficient and effective production of energy with minimal incidence of fires.

- Chemical Processing: Copper flanges are applied in chemical processing industries because of their characteristic of holding up to aggressive mediums, which makes pipelines to be corrosion free.

- Oil and Gas Industry: In pipeline and equipment used in the oil and gas sector, copper flanges are employed because of some of these features like high temperatures and pressure are a major consideration when handling such equipment.

General Applications

- Plumbing Systems: Copper flanges are widely preferred by most homeowners and contractors when installing plumbing systems in homes and other buildings because of the features such as easy to fit and do not corrode hence giving the system a leak proof connection for a long time.

- Electrical Grounding : In electrical systems, copper flanges are used for grounding purposes and this is because of its excellent electrical conductivity that enables proper grounding of electrical systems.

- Fire Suppression Systems: Copper flanges are so utilized in fire suppression systems as the component protection involves high temperatures in addition to pressure that has an impact with such crucial safety products.

- Water Treatment Plants: Specification copper flange is used in pipe line and processing units in water treatment plants to help in fighting away corrosion and bio-slime so that treated water is safe for human consumption.

- Solar Energy Systems : Copper flanges are integrated in solar energy applications in order to join pipes conveying heat transfer fluids with copper’s thermal properties and corrosion resistance for improving the system performance.