Table of Contents

In the case of Norway, healthy growth is being seen in the industrial sector; however, the same is happening in its quality material demand. So, quality copper flanges are in need in Norway. With keen interest in the best industrial standards, C-Fit Copper Fitting Manufacturer is looking forward to getting excellent copper flanges fitting in every industry standard. A product line provides all companies with services and guarantees that every product will be aggressive and reliable. Therefore, to gain the proper engineering and provide utmost customer satisfaction, we are your friend associate in supplying copper flanges for Norway.

Copper Flanges Manufacture, Dealer and Exporter in Norway :- Properties

The copper flanges have peculiar properties which make them exceptionally in demand for most applications. With these desired properties, they would provide strength, performance, and compatibility with any kind of environment. The considerations would become very important in aiding industries to decide upon the right kind of flanges for their purposes.

- Corrosion Resistance : The copper flanges have excellent corrosion resistance, making them ideal for usage in harsh environments. This ensures the lifetime period, which over time reduces maintenance and reliability cost in highly critical applications.

- High Thermal Conductivity : Since copper is very conductive in terms of heat, flanges are great heat dissipaters. This is quite an important characteristic in applications where temperature control is highly critical to the application, like in HVAC equipment, heat exchangers, among others.

- Ductility : Copper is an extremely ductile material and shapes and forms very well without losing one’s integrity. This means one has very friendly designs for any installation requirement.

- Strength : Though they are light in weight, copper flanges possess a great amount of tensile strength and thus are very useful especially in high-pressure applications. The strength ensures that they do not break down under demanding conditions.

- Electrical Conductivity: Copper has very good electrical conductivity that is why copper is used for those applications in which electrical connections are there, including power plants and electrical equipment.

- Recyclability : Copper is 100% recyclable without losing any property. Such property makes copper flanges a good option in the eco-friendly industries, therefore, highly preferred in this generation of environment-conscious industries.

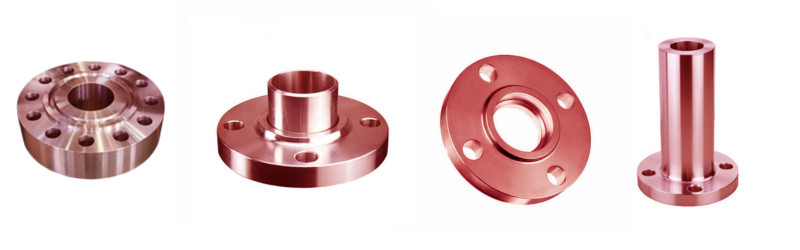

Copper Flanges in Norway :- Types

There are different types of copper flanges depending upon the application and the environment in which they are going to work; therefore, knowledge of the types can help in recognizing the appropriate flange for specific requirements and can thus ensure maximum performance and safety of the industries.

Copper Weld Neck Flanges in Norway

Their necks are longer and thus, provide an easy weld between the flange and pipe. Their high pressure would be ideal because they have great strength and integrity at the weld point.

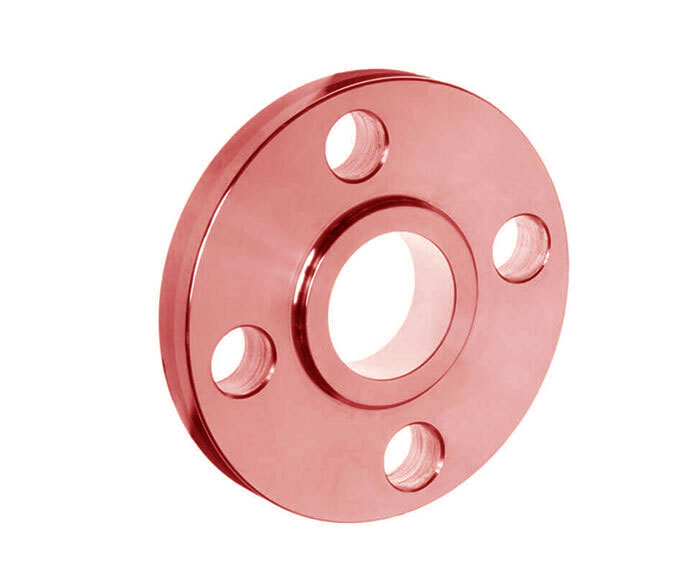

Copper Slip-on Flanges in Norway

The flanges slipped over the pipe. They are the most convenient type of flange and rather flexible. Generally, they are suitable for low-pressure applications, and in all cases, they may be welded in place to avoid leakage

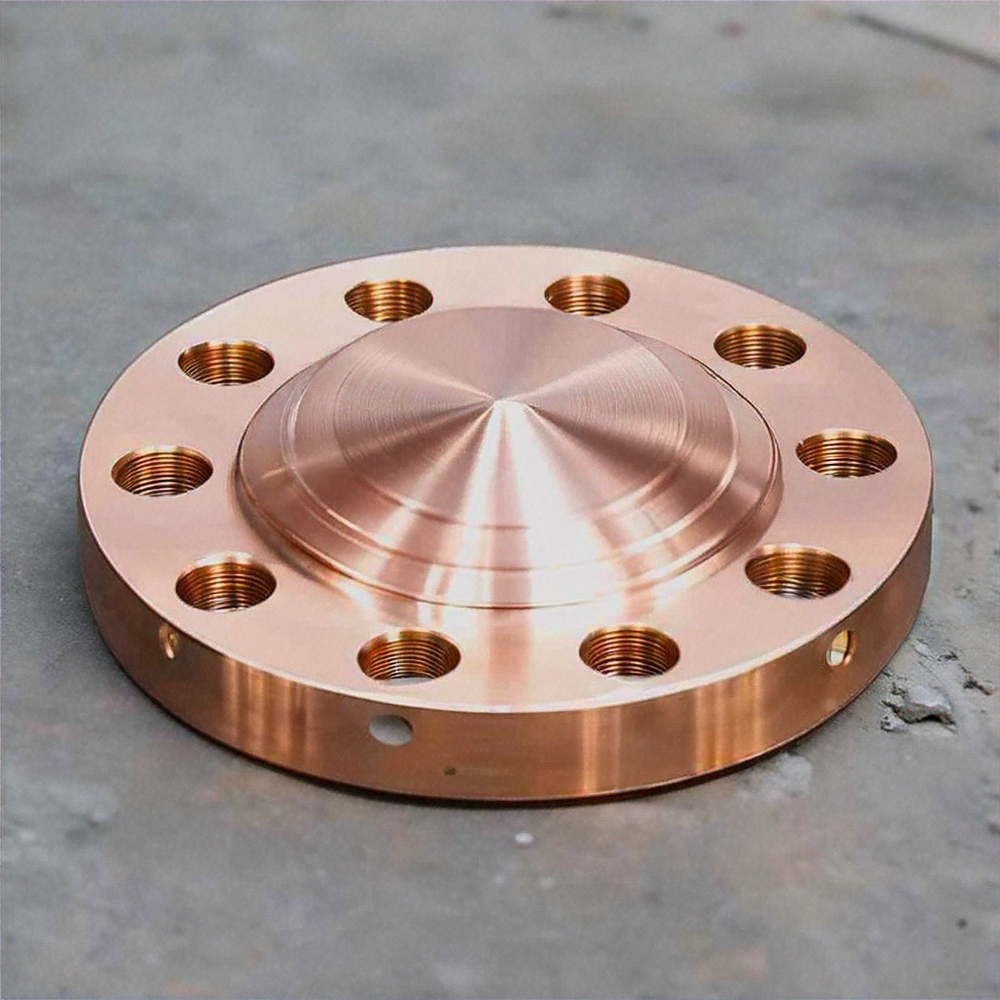

Copper Blind Flanges in Norway

A blind flange is one of the seal elements applied at the end of a pipeline. Maintenance, added with in-service inspection, is being made with the application of these elements to seal that region. These blind flanges will make for a closure but permit accessibility to the pipe in the future.

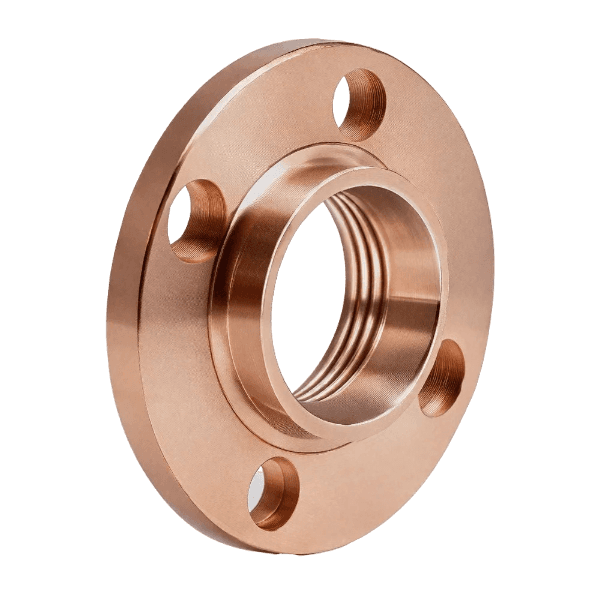

Copper Threaded Flanges in Norway

Threading Flanges they can be screwed in and out of a pipe by the internal thread. They are used when welding becomes impossible as it offers easy strength connection.

Copper Socket Weld Flanges Norway

Socket Weld Flanges are used for small diameter pipes which has a socket in it where the pipe is fitted. In this type of flange, the fluid can ensure a smooth and turbulence-free flow.

Copper Lap Joint Flanges in Norway

The lap joint flange contains two parts. It is used where frequently assembling and disassembling is required. Ends are overlapped so that a slip joint may be obtained.

Copper Flanges Manufacture, Dealer and Exporter in Norway : Size, Weight, Dimension Table and Chart

For copper flanges, appropriate sizes, weights, and measurements are taken into consideration in your application. They are not only compatible with piping systems but also the overall performance and integrity of an installation. A correctly sized flange ensures that you receive adequate pressure ratings and flow requirements and limits leaks or failures. Thus, familiarity with the dimensional specifications lends to having a safe and efficient connection-an aspect significantly important in the decision-making process when selecting a flange.

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. of Hub Top | SO LTH | WN LTH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.5 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.5 | 1.05 | 0.56 | 2 |

| 1 | 4.25 | 0.5 | 2 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.5 | 4 | 0.62 | 3.5 | 1.7 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.9 | 0.81 | 2.38 |

| 2 | 6 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7 | 0.81 | 4.12 | 4 | 0.75 | 5.5 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.5 | 0.88 | 5 | 4 | 0.75 | 6 | 3.57 | 3.07 | 4.25 | 3.5 | 1.12 | 2.69 |

| 31⁄2 | 8.5 | 0.88 | 5.5 | 8 | 0.75 | 7 | 4.07 | 3.55 | 4.81 | 4 | 1.19 | 2.75 |

| 4 | 9 | 0.88 | 6.19 | 8 | 0.75 | 7.5 | 4.57 | 4.03 | 5.31 | 4.5 | 1.25 | 2.94 |

| 5 | 10 | 0.88 | 7.31 | 8 | 0.88 | 8.5 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11 | 0.94 | 8.5 | 8 | 0.88 | 9.5 | 6.72 | 6.07 | 7.56 | 6.63 | 1.5 | 3.44 |

| 8 | 13.5 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16 | 1.12 | 12.75 | 12 | 1 | 14.25 | 10.88 | 10.02 | 12 | 10.75 | 1.88 | 3.94 |

| 12 | 19 | 1.19 | 15 | 12 | 1 | 17 | 12.88 | 12 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14 | 2.19 | 4.94 |

| 16 | 23.5 | 1.38 | 18.5 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18 | 16 | 2.44 | 4.94 |

| 18 | 25 | 1.5 | 21 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18 | 2.62 | 5.44 |

| 20 | 27.5 | 1.62 | 23 | 20 | 1.25 | 25 | 20.2 | 19.25 | 22 | 20 | 2.81 | 5.62 |

| 22 | 29.5 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22 | 3.07 | 5.82 |

| 24 | 32 | 1.81 | 27.25 | 20 | 1.38 | 29.5 | 24.25 | 23.25 | 26.12 | 24 | 3.19 | 5.94 |

Copper Flanges Manufacture, Dealer and Exporter in Norway :- Uses

Copper flanges have become one of the essentials for both industrial and general usages in Norway. From their extensive use in construction, manufacturing, and energy sectors, these versatile flanges can be used and applied in various fields. If the business organizations can appreciate the multiple usages then they can take benefits of the copper flanges for better operations.

Industrial Applications

- Oil and Gas Industry : Copper Flanges are applied to pipelines in oil and gas transfer to offer a proper seal under the influence of pressure.

- HVAC Systems : They can be efficiently managed thermal problems by their application in heating, ventilation, and air-conditioning systems for conserving the energy required.

- Power Generation : At the power plants, copper flanges help out with connection work amongst different parts so that there would be no cut in electricity generation.

- Marine Applications : The corrosion property of copper flanges makes it apt for the marine environment, which makes them tough and longer lasting.

- Chemical Processing : Copper flanges are in use in chemical plants since they bear corrosive substance makes it safe and also performs the job properly.

Common Applications

- Plumbing Systems : The primary use of copper flanges, in residential and commercial plumbing, is for piping systems since it offers strong connections.

- Heating Systems : They are important for radiant heating as well as other purposes, so that the spread of heat takes place efficiently.

- Automotive Industries : Copper flanges are utilized in various applications within the automotive industries for performance and safety factors.

- Construction : It’s a structural application, wherein copper reliable connections are provided on different building materials.

- Arts and Crafts : Under the area of decorative applications, copper flanges also exemplify the aesthetic appeal of copper in artistic designs.