Table of Contents

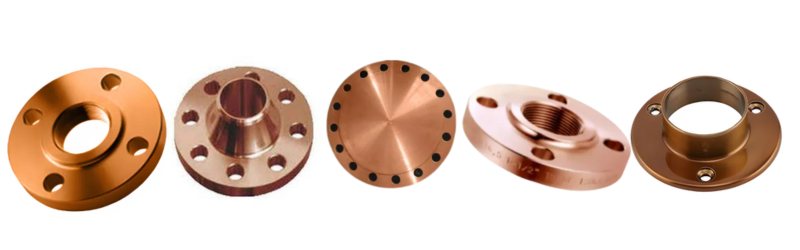

Being a manufacturer, dealer, and exporter in Oman we specialize in copper flanges for industrial and commercial uses. As for our copper flanges, High quality raw materials are adopted to guarantee high strength, high corrosion resistance, high working performance and other excellent characteristics in severe working conditions.

Here is the list of the flanges that we supply; Weld Neck Flanges, Slip-On Flanges, Blind Flanges, Threaded Flanges, Socket Weld Flanges, and Orifice Flanges with different specifications including Oil and Gas, Petrochemical, and Water Treatment Industries. Key skills in precision engineering coupled with quality assurance guarantees conformity to international standards with tight leak proof connections. Therefore, we guarantee that our deliveries will be on time, while our customer care will be professional in a way that distinguishes us as the best suppliers of Copper flange in Oman’s ever growing industrious sector.

Copper Flanges manufacture, dealer, Exporter in Oman :- Properties

- Durability: Copper flanges are very strong and resilient to mechanical pressure and physical degrading effects from the environment for invariably long durations.

- Corrosion Resistance: Flanges made of copper do not corrode easily hence their ability to offer the necessary flange performance and durability requisite for the less friendly environment.

- Thermal Conductivity: Good thermal conductivity of copper flanges implies that they are useful in heat exchange processes for e. g. they do not trap heat.

- Strength: Copper flange a have very high strength to enable it to work under very high pressure and high stressed areas.

- Ease of Fabrication: Copper offers a favorable response to the process of machining and fabrication, hence, its ability to be tuned to systems that need it.

- Aesthetic Appeal: The color reddish brown of copper is an added advantage because it gives the required aesthetic touch to the piping systems.

- Leak-Proof Sealing: The copper flanges are specially designed to assure ultimate accuracy and are absolutely critical when it comes to the flange connections that are required to prevent leakage and all the consequent issues in regards to the overall system performance and safety.

- Versatility: Good for weld neck, slip-on, blind, threaded, socket weld, and orifice flanges suitable for their many uses in the sector.

Copper Flanges manufacture, dealer, Exporter in Oman :- Types

The common kinds of flanges fabricated with copper are weld neck, slip-on, blind, threaded, socket weld, and orifice flanges for use in Oman. Both types serve certain industries’ needs and provide easy reliable leak-free connections and superior corrosion protection. These quite universal flanges are indispensable for such fields as oil and gas, petrochemical, and water treatment.

Weld Neck Copper Flanges in Oman

Weld neck copper flanges are used for high pressure services which have longer tapered hub providing enhanced load and stress bearing capability. This feature enhances structural security and totally eliminates leakage; they are very durable and perfect for rugged /industrial applications.

Threaded Copper Flanges in Oman

Copper threaded flanges are designed for a smooth non-welded connection with the help of screwing on the flanges with external threads on to the pipe end. Such flanges can easily be assembled and disassembled and are very durable with the ability to resist corrosion.

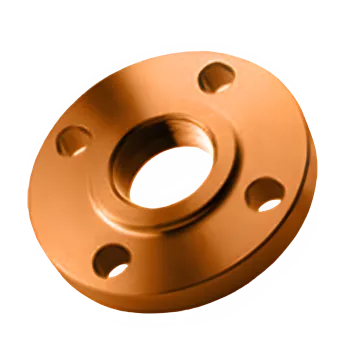

Slip-On Copper Flanges in Oman

Slip-on copper flanges are fitless over the pipe end, the flange is welded to the pipe. As for its details these types are suitable for low to medium pressure applications, using the product is relatively cheap and highly durable as well as highly corrosion resistant.

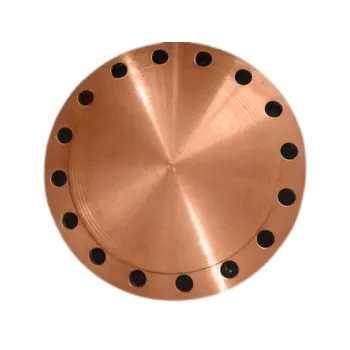

Blind Copper Flanges in Oman

Copper blind flanges are applied to shut off the pipelines or pressure vessels’ openings isolated the flow. It gives better performance & excellent corrosion resistance helps to support system integrity & aid future work on such systems.

Socket Weld Copper Flanges in Oman

Copper socket weld flanges have an outwardly projecting step that fits over the end of the pipe and comes to a flush level with it once welded. They are suitable for high stress applications since they have the best fatigue strength as well as highly resistant to corrosion.

Orifice Copper Flanges in Oman

Orifice copper flanges are intended for accurate control of the flow as well as measurement in the piping layout. They have a precision drilled orifice plate that assists in the flow measurement; thus, they are used where accurate control of fluid flow is necessary.

Copper Flanges manufacture, dealer, Exporter in Oman :- Size, Weight , Dimensions Tables

Copper flanges size, weight and dimensions tables give useful data to support the selection of the suitable flange for the right fitting. Some of the table dimensions given include but are not limited to outer diameter, bolt hole spacing, thickness etc, to ensure inter-changeability. In this case, size and weight measurement information ensure that installation is easier and that the overall systems performance is not compromise.

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. of Hub Top | SO LTH | WN LTH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.5 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.5 | 1.05 | 0.56 | 2 |

| 1 | 4.25 | 0.5 | 2 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.5 | 4 | 0.62 | 3.5 | 1.7 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.9 | 0.81 | 2.38 |

| 2 | 6 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7 | 0.81 | 4.12 | 4 | 0.75 | 5.5 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.5 | 0.88 | 5 | 4 | 0.75 | 6 | 3.57 | 3.07 | 4.25 | 3.5 | 1.12 | 2.69 |

| 31⁄2 | 8.5 | 0.88 | 5.5 | 8 | 0.75 | 7 | 4.07 | 3.55 | 4.81 | 4 | 1.19 | 2.75 |

| 4 | 9 | 0.88 | 6.19 | 8 | 0.75 | 7.5 | 4.57 | 4.03 | 5.31 | 4.5 | 1.25 | 2.94 |

| 5 | 10 | 0.88 | 7.31 | 8 | 0.88 | 8.5 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11 | 0.94 | 8.5 | 8 | 0.88 | 9.5 | 6.72 | 6.07 | 7.56 | 6.63 | 1.5 | 3.44 |

| 8 | 13.5 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16 | 1.12 | 12.75 | 12 | 1 | 14.25 | 10.88 | 10.02 | 12 | 10.75 | 1.88 | 3.94 |

| 12 | 19 | 1.19 | 15 | 12 | 1 | 17 | 12.88 | 12 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14 | 2.19 | 4.94 |

| 16 | 23.5 | 1.38 | 18.5 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18 | 16 | 2.44 | 4.94 |

| 18 | 25 | 1.5 | 21 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18 | 2.62 | 5.44 |

| 20 | 27.5 | 1.62 | 23 | 20 | 1.25 | 25 | 20.2 | 19.25 | 22 | 20 | 2.81 | 5.62 |

| 22 | 29.5 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22 | 3.07 | 5.82 |

| 24 | 32 | 1.81 | 27.25 | 20 | 1.38 | 29.5 | 24.25 | 23.25 | 26.12 | 24 | 3.19 | 5.94 |

Copper Flanges manufacture, dealer, Exporter in Oman :- Uses

Copper flanges are used extensively for mating and joining the piping systems where it is to be applicative in oil and gas, chemical industries, HVAC, etc. They offer, herald, sealant, closure with no leakage, easy connection and accessibility for maintenance, and non-corrosiveness and heat damage thus exhibiting high performance and operation.