Table of Contents

Copper Fitting Manufacturer is your number one source of copper flange corporation in Sri Lanka. We are a leading manufacturer, dealer and exporter of copper flanges having different types of flanges which are available as per International standards. We ensure that our product serves the requirement and need of our clients for a long-term in different application use. Our promise is to offer quality solutions that embrace high standards in technology in its manufacturing and high quality input materials. Please use the links below to navigate our large database and learn about how we can supply you with copper flanges. Choose us for professional assistance and extraordinary quality of each delivery

Copper Flanges Manufacture, Dealer and Exporter in Sri Lanka :- Properties

Copper flanges possess desirable properties that are responsible for the material’s popularity in different industries. They respond to corrosion naturally and due to their high order conductivity feature in high heat and electricity operations. Secondly copper flanges are easy to machine allowing a noble finish and made to order production. All these properties make them suitable for use in pipining systems since they will be reliable and efficient.

- Corrosion Resistance

Copper flanges are very durable in terms of corrosion and more so, in any environment that is moist. This property is useful to avoid fatigue on the flange and most systems to retain their efficiency since there wears off with time. Copper flanges are therefore suitable for use in plumbing processes and systems, cooling and air-conditioning systems, and even in marine environments because of their resistance to moisture. - Thermal Conductivity

Since copper flanges possess high thermal conductivity, such flanges tend to transfer heat effectively. They are ideal for use in systems that require proper dissipation of heat such as heat exchangers and coolers. It is due to this that they enables efficient heat transfer hence maintaining the right operating temperatures thereby enhancing system performance. - 3. Electrical Conductivity

Copper flanges are also good conductor of electricity hence making them suitable for electrical connections. These make them have the ability of conducting electricity with little loss of energy making them ideal for use in circuits and systems. It provides reliable contacts and improves performance of electrical related equipment on this property. - 4. Machinability

Machinability: Copper flanges are particularly well known for their good machinability features that facilitate fabrication of flows that can meet desired specifications. They property allows manufactures to be able to create flanges that fit specific needs because every system will need a perfect fit. They are also easy to machining for repairs as well as modification thus are suitable for use in industries that may need frequent changes. - Ductility and Malleability

Copper is also Ductile and Malleable which means that it can be stretched to form conductors like wires and can be fashioned into different forms without it being able to get fractured. This property enables copper flanges to be subjected to mechanical stress and or pressure and still not to be affected structurally. It helps them be able to meet and perform in different installation environments and operational conditions. - Aesthetic Appeal

Besides these practical purposes, copper flanges boast noble appearance because of their natural colour – warm reddish-brown. This makes them a favourite in architecture where the look of the glass is given preference over the functionality. This likely increase the aesthetic value of installations whereby the finish is also effective and aesthetically appealing

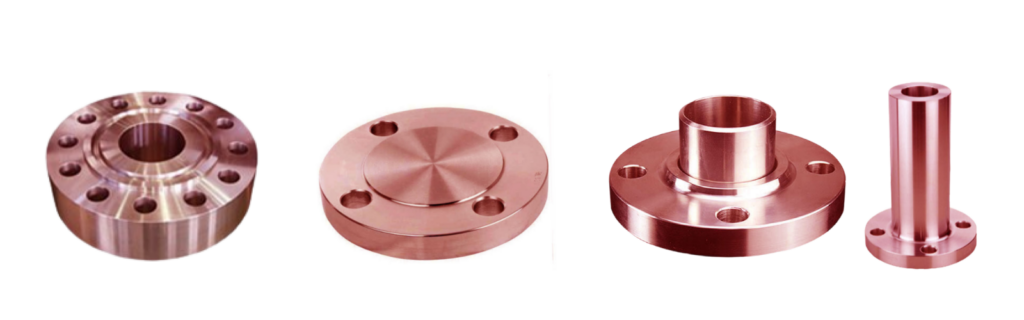

Copper Flanges in Shri Lanka :- Types

Copper flanges are of various types depending on the need that is required in a particular project. These flanges come in standard shapes as well as special shapes that meet the compatibility and use across the various industries. This makes them very easy to connect with piping systems which makes long the favorite of engineers and manufacturers. It will therefore be pertinent to discuss the various categories of copper flanges so as to make the right choice.

Slip-On Flanges

Slip-on flanges are designed in such a way that it can be slipped over the pipe end making the connection quite easy and convenient. They are relatively easy to install and can also be aligned easily, thus they are commonly used in several piping systems. The design of their arteries permits welding at the outside of the joint making the union stronger.

Copper Weld Neck Flanges

Weld neck flanges have a long, odonves, tapered neck that gradually merges into the pipe in order to offer a very sound and secure assembly. Due to the low stress concentration this design is well suited to high pressure applications. Weld neck flanges are used in service where fitness for purpose is critical.

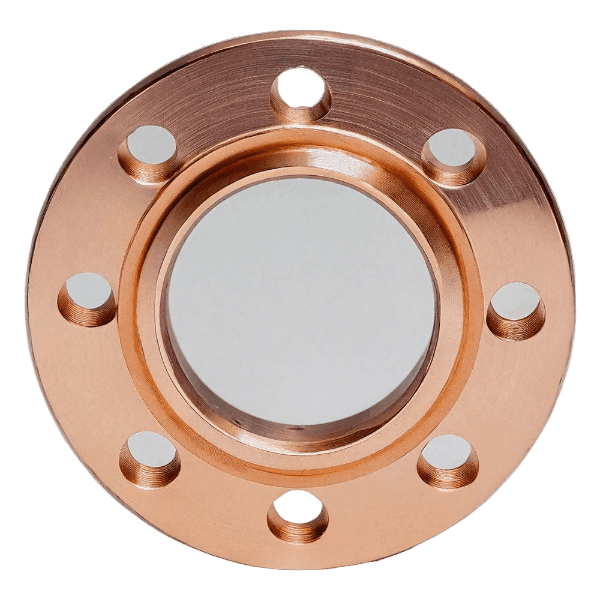

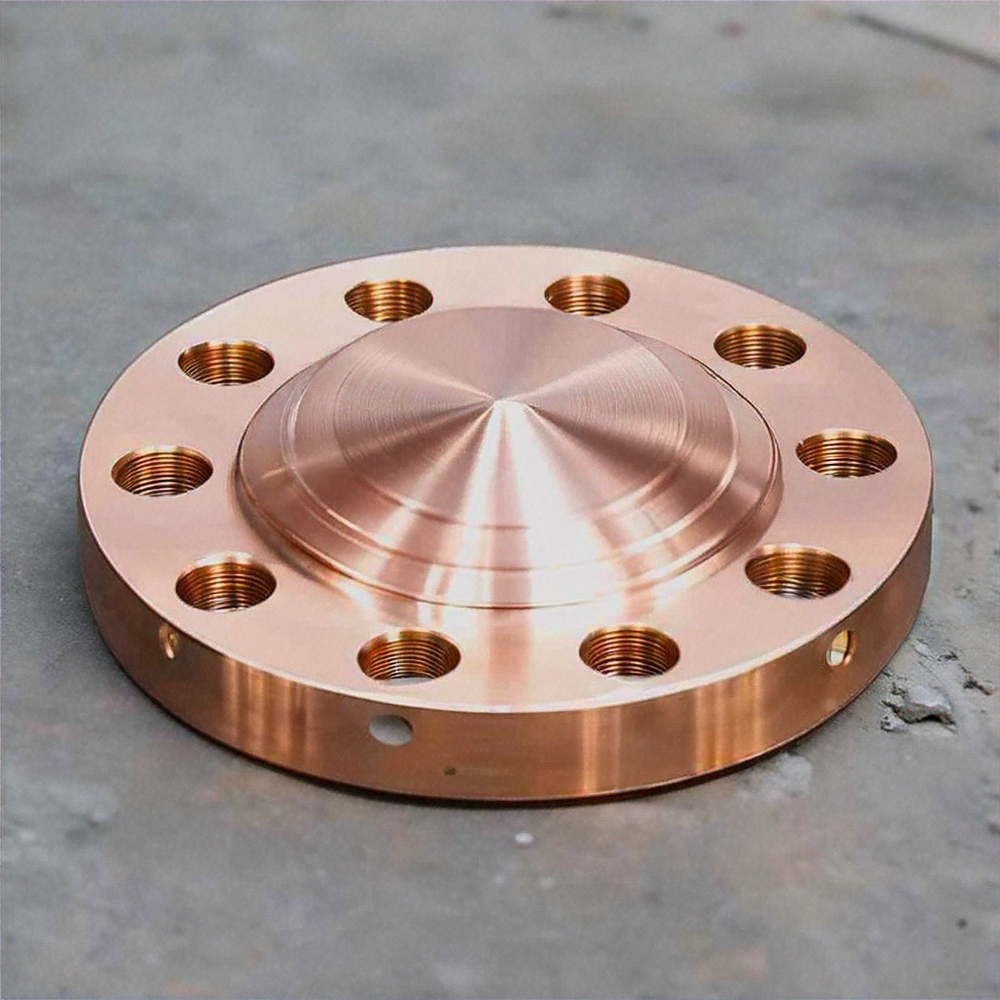

Copper Blind Flanges

Blind flanges are flanges with a solid body with no hole through it they are used to seal the end of a piping system. They are very essential in hindering the movement of fluids or gases and they are widely employed in maintenance purposes. A strong construction guarantees a tight and secure seal which even increases safety in these sectors.

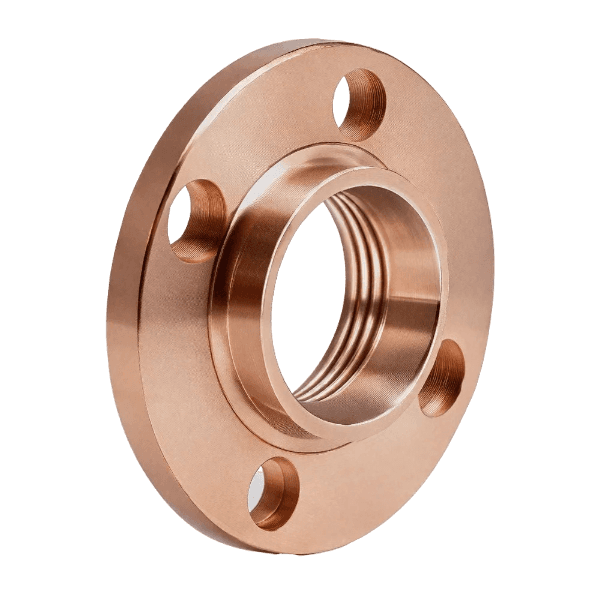

Copper Threaded Flanges

Threaded flanges come as internal threaded flanges so they can just be screwed on to any pipe. This characteristic permits quick setup and demolition and will not require welding and as such is well suited to non permanent or below force use. It gives a proper fit and this makes them efficient in different applications.

Copper Socket Weld Flanges

Socket weld flanges are applied for joining pipes with the socket formed especially for the pipe end. These design make sure of having a close connection especially when working under pressure. The welding process take place at the interior of the flange in order to minimize disruptions in the smooth stream or flow of the fluid.

Copper Lap Joint Flanges

Lap joint flanges are used together with a stub end and therefore this makes it easier to align or disassemble them. It is important to use this type of flange especially in industries where there is constant checking and amendment or replacement of flanges. A prominent feature of lap joint flanges is the fact that flanges can be readily removed from the joint and joined again if necessary and so it makes them appropriate for use in several sectors.

Copper Flanges Manufacture, Dealer and Exporter in Shri Lanka : Size, Weight, Dimension Table and Chart

Once you determine the required copper flanges for your project, knowing their size, weight, and dimensions is a basis for compatibility with existing systems. Also, our extensive tables include other measurements such as the nominal size, weight, and dimensional measurements of the flanges. These tables are indeed great tools for the engineer and procurement professional to ensure a proper specification for any project. Having an appropriate table to refer to, you can pick the right copper flanges that match both functional and code requirements.

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. of Hub Top | SO LTH | WN LTH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.5 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.5 | 1.05 | 0.56 | 2 |

| 1 | 4.25 | 0.5 | 2 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.5 | 4 | 0.62 | 3.5 | 1.7 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.9 | 0.81 | 2.38 |

| 2 | 6 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7 | 0.81 | 4.12 | 4 | 0.75 | 5.5 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.5 | 0.88 | 5 | 4 | 0.75 | 6 | 3.57 | 3.07 | 4.25 | 3.5 | 1.12 | 2.69 |

| 31⁄2 | 8.5 | 0.88 | 5.5 | 8 | 0.75 | 7 | 4.07 | 3.55 | 4.81 | 4 | 1.19 | 2.75 |

| 4 | 9 | 0.88 | 6.19 | 8 | 0.75 | 7.5 | 4.57 | 4.03 | 5.31 | 4.5 | 1.25 | 2.94 |

| 5 | 10 | 0.88 | 7.31 | 8 | 0.88 | 8.5 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11 | 0.94 | 8.5 | 8 | 0.88 | 9.5 | 6.72 | 6.07 | 7.56 | 6.63 | 1.5 | 3.44 |

| 8 | 13.5 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16 | 1.12 | 12.75 | 12 | 1 | 14.25 | 10.88 | 10.02 | 12 | 10.75 | 1.88 | 3.94 |

| 12 | 19 | 1.19 | 15 | 12 | 1 | 17 | 12.88 | 12 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14 | 2.19 | 4.94 |

| 16 | 23.5 | 1.38 | 18.5 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18 | 16 | 2.44 | 4.94 |

| 18 | 25 | 1.5 | 21 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18 | 2.62 | 5.44 |

| 20 | 27.5 | 1.62 | 23 | 20 | 1.25 | 25 | 20.2 | 19.25 | 22 | 20 | 2.81 | 5.62 |

| 22 | 29.5 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22 | 3.07 | 5.82 |

| 24 | 32 | 1.81 | 27.25 | 20 | 1.38 | 29.5 | 24.25 | 23.25 | 26.12 | 24 | 3.19 | 5.94 |

Copper Flanges Manufacture, Dealer and Exporter in Shri Lanka :- Uses

Copper flanges are one of the most important elements of such widely used products in numerous industries of Sri Lanka. Their durability, resistance to corrosion, and excellent thermal and electrical properties make them an excellent choice for widespread industrial and other applications, ensuring that they are able to perform the intended functions and reach the right conditions for operation under different environments. An ever-expanding industrial requirement for copper flanges makes them a necessary component in systems to ensure their efficiency and robust performance. Some of the common applications of copper flanges are placed under industrial and general uses.

Industrial Applications

- Manufacturing Plant

In a manufacturing plant, copper flanges are widely used for piping fluid and gases transportation. Due to its strength and resistance to corrosion, it is used in places that involve handling varied chemicals and processes in order to ensure safety and optimum efficiency. - power generation

Copper flanges are really important within the power generation plants. Used in steam and cooling cycles, it has excellent thermal conductivity that ensures optimal temperature conditions. - Marine Uses

With such an extensive coastline, Sri Lanka uses many copper flanges within marine settings. Copper does not corrode against salt water and, therefore, is suitable for use in ship building or offshore platforms, etc. - HVAC Systems

In HVAC systems, copper flanges are essential components linking ductwork to piping. Reliability ensures satisfactory airflow and control of temperature for the maintenance of a comfortable environment indoors.

Common Applications

- Plumbing Systems

Copper flanges are very common in residential and commercial plumbing systems. On the water supply lines, they provide tight connections ensuring that operation is leak-free and performs for a long time. - Architecture Features

Copper flanges also provide an aesthetic value; therefore, they are fit for architectural use. They are used most of the times in installations, handrails, and decorative features to enhance the aesthetic beauty of a building and at the same time be a useful part. - Automotive

Within the automotive sector, copper flanges are used in several auto parts including the exhaust system and cooling system. The strength of copper and its strength make it fit to increase the performance and life expectancy of the car. - Food and Beverage Industry

Copper flanges are used also in the food and beverage industry for piping systems and equipment utilized in food processing. Their antimicrobial properties make them hygienic and safe, so they usually get preferred for any application involving food processing.