Table of Contents

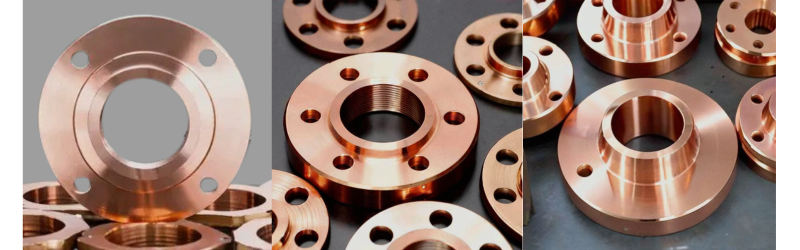

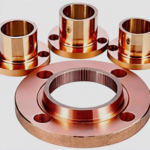

Copper Fitting Manufacturer is a renowned company in UK that deals with copper flanges both as a manufacturer, dealer and exporter. Copper flanges manufactured and designed by us satisfy extreme standards of the different industries they will be used for. This makes sure that our products are among the best in the market or as the customer demands from an international firm. Due to our commitment to deliver high quality services, companies in the entire United Kingdom value our services. From specific requirements to the ready to use products, Kenwood is able to address clients’ requirements. Choose us as your reliable supplier of premium copper flanges enhancing your business activities.

Copper Flanges manufacture, dealer, Exporter in UK :- Properties

Copper flanges are singled out for their outstanding properties in making them ideal to use in a number of industries. These flanges come with high levels of corrosion, meaning installation will be highly durable in the most extreme conditions. They include; their high thermal and electrical conductivity make them suitable for high performance systems. Also, copper flanges are very ductile while at the same time being strong and they offer secure connections in various applications.

- Corrosion Resistance- Copper flanges have got great resistivity towards corrosion and have great resistance to water, air as well as most of the chemicals. This characteristic makes them suitable for use in special areas where other material can deteriorate quickly hence the constant need to replace them.

- Thermal Conductivity- Copper also possesses good thermal conductivity characteristics hence copper flange are capable of transferring heat effectively. This property is important in any application where control of temperature is required say in heating applications, refrigeration or air conditioning.

- Electrical Conductivity- Copper flanges also provide the much needed electrical conductivity, especially used in electric and electronics related industries. Their efficiency to conduct electrical current means they retain little energy allowing for their used widely in electrical circuits and grounds.

- Malleability and Ductility- The copper flanges exhibit high malleability and ductility which implies that it can be shaped and bent into different forms and thickness without compromising on the strength of the flange. On this property, there exists an advantage for custom designs, and the individual pieces fit tightly and securely in various applications manufacturing and installing flexibility.

- Strength and Durability- At the same time, copper flanges are flexible but they are very tough and hardy. The materials meanwhile can handle pressure and mechanical stress which makes them appropriate in industries. That’s why their durability guarantee high service life for all types of conditions.

- Antimicrobial Properties- Copper just has a way of not adversely supporting bacteria and other microorganisms, or as we may call it ‘self-sterilizing. ’ It makes copper flanges very appropriate in applications that are sensitive to bacterial presence, such as in the food processing and in the pharma industry.

- Aesthetic Appeal- It also owns lovely appearance as copper flanges which has the reddish-brown color. With time, they acquire a protective skin which helps to add the aesthetic value in architectural and design elements and making them more popular in decorative applications.

Copper Flanges manufacture, dealer, Exporter in UK :- Types

Copper flanges also have different categories where each type is aimed to provide particular use in different industries. Some of these flanges are designed depending on their shape, design and functions with the view of offering a good fit and connection. To this end it is possible to describe variety of copper flanges and determine which of them will be appropriate for use in certain conditions. You will find details on the most widely used copper flanges as per their application below.

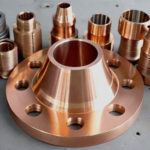

Copper Weld Neck Flanges

Weld neck flanges has a long and narrow neck on them that extends and is welded to the pipe it is attached to so the stress is focused on the pipes girth rather than the base of the flange. These flanges are suitable for use where pressure and temperature are high and where there is need for tight shutoff or leak proof joint. Some of applications include oil and gas, chemical processing, and power generation industries.

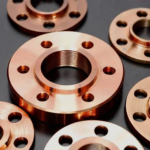

Copper Slip-On Flanges

Slip-on flanges are made so that they are slipped over the end of the pipe and then afterwards welded on. These flanges are easy to install and are normally found in use in low pressures only or systems. They are also affordable and this is one of the reasons why they are widely used in plumbing industry and heating, ventilating, and air conditioning industry, and water treatment industry.

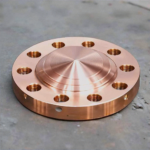

Copper Blind Flanges

Blind flanges are called where it is required to close the end of pipe or valve and halt the flow of liquid or gas. These flanges do not have a bore and is useful in systems that might in future need expansion or inspection. They are widely used in pipelines and pressure vessels and any other system where it is required to shut off a particular segment.

Copper Lap Joint Flanges

Lap joint flanges are utilized along with stub ends and they are suitable for the conditions where there is need to take apart the system regularly in order to inspect or clean it. This flange is not in direct contact with the fluid and the flange can actually turn around the pipe so that it can be easily aligned in position when assembling it. These flanges are normally found in low-pressure systems and piping systems wherein the flanges are usually removed and re-installed.

Copper Threaded Flanges

Threaded flanges are manufactured in a way that makes them to be screwed on the pipe without use of welding. These flanges are perfect for scenarios which may not allow welding of the equipment or where welding is prohibited like the use in flammable, explosive and high pressure systems. They are applied particularly in such systems as small diameter piping systems, and require less installation and maintenance efforts.

Copper Reducing Flanges-

Typically with flanges, reducers are employed for carrying out transitions between two pipes of distinct diameters. These flanges are good where vertical or horizontal space is restricted or where horizontal arrangement is possible but pipe size must be reduced to achieve pressure or flow rate. These are usually applied in chemical industries, water works and in air conditioning systems.

Copper Flanges manufacture, dealer, Exporter in UK :- Size, Weight , Dimensions Tables

It then becomes important to fully comprehend the different size, weight and dimensions that are characteristic of copper flanges if one is to warrant the correct components that are relevant to a certain project. Measuring properly will result in compatibility, optimize performance as well as assuring safety in piping systems. Comprehensive tables of our products state the necessary dimensions of the has as well as their weight depending on the type of copper flanges required. These tables provide a ready reference specifically for engineers, contractors and suppliers to enable them select the right copper flanges for their projects.

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. of Hub Top | SO LTH | WN LTH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.5 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.5 | 1.05 | 0.56 | 2 |

| 1 | 4.25 | 0.5 | 2 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.5 | 4 | 0.62 | 3.5 | 1.7 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.9 | 0.81 | 2.38 |

| 2 | 6 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7 | 0.81 | 4.12 | 4 | 0.75 | 5.5 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.5 | 0.88 | 5 | 4 | 0.75 | 6 | 3.57 | 3.07 | 4.25 | 3.5 | 1.12 | 2.69 |

| 31⁄2 | 8.5 | 0.88 | 5.5 | 8 | 0.75 | 7 | 4.07 | 3.55 | 4.81 | 4 | 1.19 | 2.75 |

| 4 | 9 | 0.88 | 6.19 | 8 | 0.75 | 7.5 | 4.57 | 4.03 | 5.31 | 4.5 | 1.25 | 2.94 |

| 5 | 10 | 0.88 | 7.31 | 8 | 0.88 | 8.5 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11 | 0.94 | 8.5 | 8 | 0.88 | 9.5 | 6.72 | 6.07 | 7.56 | 6.63 | 1.5 | 3.44 |

| 8 | 13.5 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16 | 1.12 | 12.75 | 12 | 1 | 14.25 | 10.88 | 10.02 | 12 | 10.75 | 1.88 | 3.94 |

| 12 | 19 | 1.19 | 15 | 12 | 1 | 17 | 12.88 | 12 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14 | 2.19 | 4.94 |

| 16 | 23.5 | 1.38 | 18.5 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18 | 16 | 2.44 | 4.94 |

| 18 | 25 | 1.5 | 21 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18 | 2.62 | 5.44 |

| 20 | 27.5 | 1.62 | 23 | 20 | 1.25 | 25 | 20.2 | 19.25 | 22 | 20 | 2.81 | 5.62 |

| 22 | 29.5 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22 | 3.07 | 5.82 |

| 24 | 32 | 1.81 | 27.25 | 20 | 1.38 | 29.5 | 24.25 | 23.25 | 26.12 | 24 | 3.19 | 5.94 |