Table of Contents

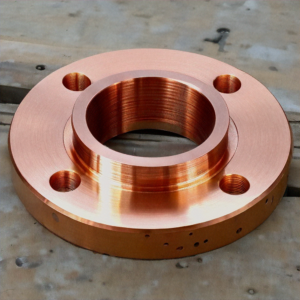

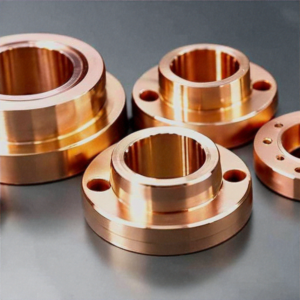

We are Copper Fitting Manufacturer – a well-established manufacturing firm that’s also a dealer and exporter of various copper products, especially copper flanges in the United States. The copper flanges that CVBAL provides are built to withstand the different stresses that a certain industry can bring, and guaranteed to have the right measurements, strength and high performance. Established products meet their requirements in terms of functionality and durability and we maintain high standards quality in all our products. Being an innovative company, and striving to ensure maximum satisfaction of our clients, we offer a range of services that are shaped specifically to fulfill the needs of our clients all across the American States. We assure you the delivery of quality in every flange that we provide.

Copper Flanges manufacture, dealer, Exporter in USA : Properties

Copper flanges are considered having some unique features and properties and that is why those are highly appreciated and favorite in multiple industries in the world. Many of these flanges offer high corrosion resisting properties, fine thermal and electric conductivities, and fine mechanical strength. The benefits thus include the ability to achieve impressive returns in the most difficult operational conditions. Below, we describe some of the most important characteristics of copper flanges that makes them popular with engineers and manufacturers.

- Corrosion Resistance

Copper flanges also offer very good level of resistance to corrosion which can be from water, air and many chemicals. This property makes them to be strong and durable so as to remain relevant in their functionality for many years without being affected by harsh or corrosive environment hence being suitable to be used in plumbing, HVAC systems and industries. - Thermal Conductivity

Since copper is conductive to heat the use of copper flanges offer better heat transfer making them ideal in applications where temperature is sensitive. Its excellent property of heat dissipation makes them suitable to use in heater, ventilators, air conditioners and refrigerators. - Electrical Conductivity

Copper is well appreciated when it comes to electrical conductivity and this also applies to copper flanges. This property makes it to have low power loss and is vital in electrical and electronics products to offer efficient electrical connections. - Strength and Durability

Although copper flanges are easily formed, these flanges possess high tensile strength that make them suitable structures for very high pressure and mechanical loads. Such durability prevents them from offering low quality connections in industrial cabins and facilities hence preventing cases of leakage or failure. - Malleability and Ductility

Copper flanges can be easily formed and are very flexible in their usage making them easily suited for different purposes. This property makes them suitable to be developed in any form of configuration as it does not compromise on the strength needed to hold the bar configuration. - Antimicrobial Properties

Copper is a mineral that has a natural ability to resist bacterial adhesion, and kill pathogenic organisms on the surface of the item. This makes copper flanges especially important where there is elevated need to use products that will not support bacterial and fungal growth, that is, use in the medical, pharmaceutical and food industries. - Aesthetic Appeal

The beauty of copper flanges is another benefit of Copper flanges The metal has a reddish-brown hue which is an added advantage because the longer it is exposed the yellowish-green patina is developed. This makes them a popular commodity as a result of their application in structural as well as aesthetic uses in architectures and interior designs.

Copper Flanges manufacture, dealer, Exporter in USA :- Types

These flanges are of many types based on the type of material used, the purpose they are to serve and the nature of the solid material they are associated with. There are several types of flanges which is why it is vital to familiarize yourself with all of them to be able to choose the right one to use in your piping systems with the right fit and performance. All these come in different types each of which has specific features that addresses various needs of the industries, be it high pressure application or ease of maintenance. Here we discuss that type of copper flanges which is most commonly used and its particular application:

Copper Weld Neck Flanges

Weld neck flanges have a long and tapered hub with the pipe being affixed to the weld. These designs afford superb tensile strength and supporting capability, thus are well suited for applications under pressures and high temperatures. They blend perfectly to the pipe which reduces stress at the flange connection thus making it leak proof and strong.

Copper Slip-On Flanges

Slip-on flanges are used to be slipped over the pipe end and it is joined with the help of welding done around the outer periphery. They are easy to install and to align and hence they are ideal for use in low pressure systems. This largely owes to the fact that pipes are relatively cheaper while at the same time being versatile in use especially in plumbing, water supply and HVAC where ease of installation is paramount.

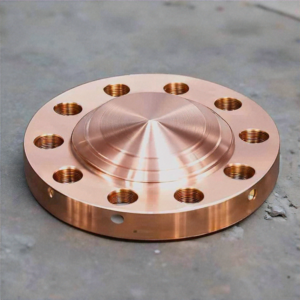

Copper Blind Flanges

Blind flanges are applied to close the end of pipe or valve, thus it stop the flow of fluids or gases in the pipe. Unflagged Flanges have no bore and they are used in isolating certain areas of the piping system for maintenance, or expansion, and so on. They are usually employed in pipework and pressure containments and other systems that are planned for periodic examination or further alteration.

Copper Socket Weld Flanges

Socket weld flanges are made for comparatively smaller diameter pipes and wherein the pipe is fitted into a socket and welded round it. This type of flange is used for pressure purpose in which an excellent seal and pressure bearing facility is needed. Socket weld flanges are used in the companies dealing with the chemical industry and in the high pressure steam systems.

Copper Lap Joint Flanges

Lap joint flanges are usually used with stub ends and it is designed in a way that they are meant to revolve around the pipe to bring them into alignment for assembly. It is especially true where the product must be dismantled for inspection or maintenance on a regular basis. Low-pressure systems and piping arrangements requiring the flanges to be positioned in various orientations are found to use these flanges.

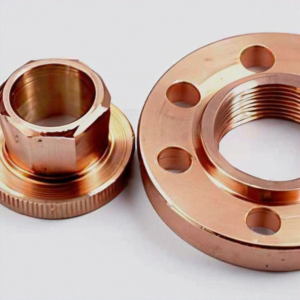

Copper Threaded Flanges

Threaded flanges consist of thread at the inner side, thus making it easy to be screwed unto the pipe without welding techniques. This design is favorable where welding is unavailable or unwanted, for example in explosive environment. Screwed flanges are usually applied to small diameter pipes and those facilities that should be disassembled frequently.

Copper Flanges manufacture, dealer, Exporter in USA :- Size, Weight , Dimensions Tables

To select and use them properly, the reader must learn more about precisely their size, weight and measuring dimensions. Our flange tables are inclusive of dimensions and kilograms in great detail as presented below for different types of flanges. The following tables are intended to help engineers, contractors and procurement personnel to make the correct selection of copper flanges for a specific project. With help of these tables, you will be able to check whether the flanges meet your technical specifications as well as integrate them into your systems.

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. of Hub Top | SO LTH | WN LTH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.5 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.5 | 1.05 | 0.56 | 2 |

| 1 | 4.25 | 0.5 | 2 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.5 | 4 | 0.62 | 3.5 | 1.7 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.9 | 0.81 | 2.38 |

| 2 | 6 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7 | 0.81 | 4.12 | 4 | 0.75 | 5.5 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.5 | 0.88 | 5 | 4 | 0.75 | 6 | 3.57 | 3.07 | 4.25 | 3.5 | 1.12 | 2.69 |

| 31⁄2 | 8.5 | 0.88 | 5.5 | 8 | 0.75 | 7 | 4.07 | 3.55 | 4.81 | 4 | 1.19 | 2.75 |

| 4 | 9 | 0.88 | 6.19 | 8 | 0.75 | 7.5 | 4.57 | 4.03 | 5.31 | 4.5 | 1.25 | 2.94 |

| 5 | 10 | 0.88 | 7.31 | 8 | 0.88 | 8.5 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11 | 0.94 | 8.5 | 8 | 0.88 | 9.5 | 6.72 | 6.07 | 7.56 | 6.63 | 1.5 | 3.44 |

| 8 | 13.5 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16 | 1.12 | 12.75 | 12 | 1 | 14.25 | 10.88 | 10.02 | 12 | 10.75 | 1.88 | 3.94 |

| 12 | 19 | 1.19 | 15 | 12 | 1 | 17 | 12.88 | 12 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14 | 2.19 | 4.94 |

| 16 | 23.5 | 1.38 | 18.5 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18 | 16 | 2.44 | 4.94 |

| 18 | 25 | 1.5 | 21 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18 | 2.62 | 5.44 |

| 20 | 27.5 | 1.62 | 23 | 20 | 1.25 | 25 | 20.2 | 19.25 | 22 | 20 | 2.81 | 5.62 |

| 22 | 29.5 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22 | 3.07 | 5.82 |

| 24 | 32 | 1.81 | 27.25 | 20 | 1.38 | 29.5 | 24.25 | 23.25 | 26.12 | 24 | 3.19 | 5.94 |