Table of Contents

Copper flanges are widely used in number of sectors due to their strength, acquire resistance and good thermal & electrical conductivity. C-Fit Copper has been successfully exhibiting as manufacturers, dealer, and suppliers of superior quality Copper flanges in India. Copper flanges: To meet the needs of all clients we offer a wide selection and all are guaranteed for durability and efficiency. Our plants are modern equipped, thus we can guarantee the compliance of our products with the international norms in terms of quality.

Our highly skilled staff makes sure that every flange is made to specification with the ability to do both off the shelf and special orders. Our copper flanges are ideal for plumbing, HVAC systems or any industrial uses; these are very efficient and highly durable. You can rely on C-Fit Copper for all your copper flange requirements, and satisfactorily avail high quality goods in the Indian market.

Copper Flanges manufacturer, dealer, supplier in India :- Properties

Copper flanges are well appreciated for the special features as a result of which they are used in various operations. Here are some key features of copper flanges. Below are features applied to copper flanges:

- High Corrosion Resistance: Copper flanges have high corrosion standard hence the flanges can be used in environment with harsh conditions hence making the flanges to have long life span.

- Superior Conductivity: Being ability Copper flanges have got desirable properties such as it is good in heat and electric transfer.

- Durability and Strength: Copper flanges as are good construction materials that are capable of supporting high pressure and high temperatures.

- Versatility: Appropriately sized and specified copper flanges for use in plumbing applications, as well as in HVAC and systems industries are availed to the market.

- Ease of Fabrication: Copper is ductile and can be easily worked with, the machines allow making a special design and the nature of the design depends on the particular necessity that is required in the particular application.

- Aesthetic Appeal: They are copper flanges and have in inherent reddish color which is quite attractive and therefore ideal for surface use.

- Eco-Friendly: Copper is reusable hence regarded as an environmental friendly metal because reusing plays a significant role in minimizing on the impacts on the natural environment.

Copper Flanges manufacturer, dealer, supplier in India :- Types

Many kinds of copper flanges are available depending on the requirements, these are slip on flanges, weld neck flanges, socket weld flanges, and blind flanges. Every one comes with its advantages like easy installation, or improved strength and sealing. These flanges are specifically useful in both commercial and industrial plumbing and are used in heating, ventilation, and air conditioning systems.

Copper Weld Neck Flange

Copper Weld Neck Flanges are flanges in which the girth weld connects the lower half of neck to the body. These flanges consist of a long tapered hub that has been designed to aid in the flow of the fluid without any form of hindrance while at the same time reducing the stress concentrations. These are suitable for applications where reliability is paramount like in oils and gas, chemicals, and power.

Copper Slip on Flanges

Copper Slip-On Flanges come in Large and Small sizes, and are considered Slip-On flanges because they are joined to the pipe rather than being threaded in place. They butt over the pipe and are later on fastened by welding thus providing a good and strong joint. Being cheap and universal, these flanges are applied to plumbing, air-conditioning systems, and other industries.

Copper Threaded Flanges

Copper Threaded Flanges do not require welding which makes it easier for systems that cannot allow welding. These flanges have internal threads that screws to external threads on the pipe hence it has tight and secure connection. They are applied mainly in low pressure and in cases of maintenance and repair work.

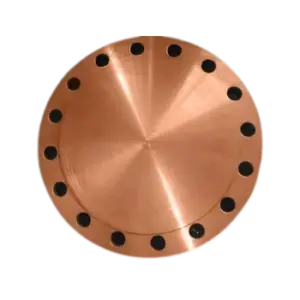

Copper Blind Flanges

Copper Blind Flanges are made to fit into pipelines and permanently closing both ends of piping systems to prevent the circulating of fluids. These solid flanges do not have bore, hence they cannot carry fluid through them; rather they are used for inspection, maintenance and testing of pipelines. They are widely used in the oil and gas industry, chemical processing and in water and waste water treatment applications.

Copper Socket Weld Flanges

These flanges are suitable for high pressure as they use Copper Socket Welds that guarantee a perfect fit and hence no leakage. These flanges have a recess in which the pipe is put, and then fillet welded to it, this making them fit well. These are suitable for slenderian pipes for the chemical processing industry, oil and gas, and power generation industries.

Copper Orifice Flanges

Copper Orifice Flanges are products sin specially utilized in flow measurement industries. Some of the components include an orifice plate that assists in calculation of the flow of liquids and/or gases. Due to increased precision, these flanges can be employed in almost all segments of the market ranging from oil and gas production well as treatment of water and handling of chemicals with utmost precision.

Copper Flanges manufacturer, dealer, supplier in India :- Size Table

The Size Table of Copper Flanges lists down the necessary measurements of the different flange styles like weld neck, slip-on, threaded, blind, socket weld, and orifice flanges. This format defines diameter ranges throughout, the thickness and other vital attributes meant to be suitable for the intended use in plumbing and industrial technologies.

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. of Hub Top | SO LTH | WN LTH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.5 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.5 | 1.05 | 0.56 | 2 |

| 1 | 4.25 | 0.5 | 2 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.5 | 4 | 0.62 | 3.5 | 1.7 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.9 | 0.81 | 2.38 |

| 2 | 6 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7 | 0.81 | 4.12 | 4 | 0.75 | 5.5 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.5 | 0.88 | 5 | 4 | 0.75 | 6 | 3.57 | 3.07 | 4.25 | 3.5 | 1.12 | 2.69 |

| 31⁄2 | 8.5 | 0.88 | 5.5 | 8 | 0.75 | 7 | 4.07 | 3.55 | 4.81 | 4 | 1.19 | 2.75 |

| 4 | 9 | 0.88 | 6.19 | 8 | 0.75 | 7.5 | 4.57 | 4.03 | 5.31 | 4.5 | 1.25 | 2.94 |

| 5 | 10 | 0.88 | 7.31 | 8 | 0.88 | 8.5 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11 | 0.94 | 8.5 | 8 | 0.88 | 9.5 | 6.72 | 6.07 | 7.56 | 6.63 | 1.5 | 3.44 |

| 8 | 13.5 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16 | 1.12 | 12.75 | 12 | 1 | 14.25 | 10.88 | 10.02 | 12 | 10.75 | 1.88 | 3.94 |

| 12 | 19 | 1.19 | 15 | 12 | 1 | 17 | 12.88 | 12 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14 | 2.19 | 4.94 |

| 16 | 23.5 | 1.38 | 18.5 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18 | 16 | 2.44 | 4.94 |

| 18 | 25 | 1.5 | 21 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18 | 2.62 | 5.44 |

| 20 | 27.5 | 1.62 | 23 | 20 | 1.25 | 25 | 20.2 | 19.25 | 22 | 20 | 2.81 | 5.62 |

| 22 | 29.5 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22 | 3.07 | 5.82 |

| 24 | 32 | 1.81 | 27.25 | 20 | 1.38 | 29.5 | 24.25 | 23.25 | 26.12 | 24 | 3.19 | 5.94 |

Copper Flanges manufacturer, dealer, supplier in India :- Uses

Copper flanges are widely used in nearly all industries due to the following characteristic of copper. Nuts and bolts are applied in plumbing for holding applications while in heating, ventilating, and air conditioning or HVAC for passageway of air or airflow while in chemical processing they are applied for protection from the effects of corrosion. More so, they find uses in operations such as the oil and gas pipelines since such seals are vital in a pipeline facility given that high pressure is involved. Copper alloys are most suitable for electrical requirements because of its properties like thermal and electrical conductivity and desired for heat exchanger purposes.

Industrial Applications:

- Heating Ventilation and Air Conditioning systems (HVAC) : Copper flanges are also utilized in HVAC in connection of the pipes and ducting or in linking them up. From the structure of their crystals they possess high coefficient of thermal conductivity and thus are used in heat transfer processes.

- Plumbing and Water Supply Systems: It includes and refers to what is known and called the pipe-line industry and the water supply organization. Copper flanges are generally suitable for use in most of the plumbing systems to couple copper pipes in place. They provide the best sealing, lasting and resistant to corrosion in water delivery systems thus; dependable.

- Electrical Power Distribution: Copper flanges are therefore used in electrical systems to join copper conductor and/or cables. Ideally, they have high electrical conductivity; therefore, they result to minimal power loss during power transmission.

- Oil and Gas Industry: Copper flanges are applied where pipelines have to be connected that transmit the fluids that contain corrosive and eroding agencies such as in the oil and gas sector. Because of this resistance they can be used in offshore and onshore conditions.

- Refrigeration and Cooling Systems: Copper flanges are employed in the modern refrigeration units and coolers for the connection of pipes that join the circuits used in transporting the refrigerants. They are important when it comes to cooling cycles efficiency.

- Chemical and Petrochemical Plants: Copper flanges in chemical processing industries are used to connect the circuits of pipes for the transfer of chemicals, acid and gaseous forms. This also means that the various systems employing this Copper will be safer as well as longer lasting due to the freedom from attacks by other chemicals.

- Marine Applications: Copper flanges are applied in marine applications for instance in construction of ships, and other structures that exposed to sea water, where copper flanges MUST be able to withstand the nature of sea water corrosion.