Table of Contents

Among the prominent manufacturers and exporters of copper lugs based in India is the establishment known as C-Fit Copper that targets clients in Kuwait and other international markets. Manufacturers and industries, who are in search of superior quality and dependable electrical products, consider C-Fit Copper as their one-stop solution. Copper lugs being their specialty, the company provides a wide selection of products that can provide high performance standards as well as meet regulatory benchmarks.

These copper lugs manufactured by C-Fit Copper provide electrical connection solutions ranging from high conductivity to corrosion resistance. Policies on innovation and customer satisfaction guarantee customers in Kuwait receive effective products accompanied by excellent service and assistance. For industrial, commercial or residential projects, C-Fit Copper has the capability and products to fulfill the electrical requirements of the fast growing market in Kuwait.

Types of Copper Lugs:

Copper Lugs

Copper lugs have excellent electrical conductivity and corrosion hence offering reliable connection in various electrical applications such as in industrial applications, home electric wiring, among others.

Copper Compression Lugs

Copper compression lugs are a practical method of creating secure, long-lasting connections that are resistant to both corrosion and fatigue, and suitable for use in a wide range of industrial and commercial environments.

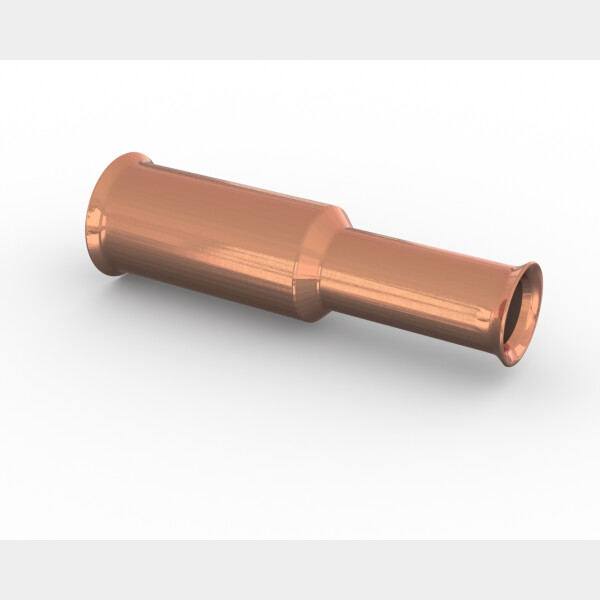

Copper Reducing Lugs

Copper reducing lugs are electrical terminals that are used to connect cables of different cross-sections in order to guarantee electrical connection which allows for variation in cable dimensions in circuits.

Copper lugs Specification:

C-Fit Copper is an Indian company that produces copper lugs with certain dimensions regarding the electrical needs of the customers. C-Fit copper lugs are produced with respect to the standards of the industry and ensure high conductivity, as well as protection against corrosion and mechanical stress. They come in several sizes and types to provide safe electrical connections suitable for a plethora of uses in various industries.

| Parameter | Description | Specification |

|---|---|---|

| Material | Copper | ASTM B152, Grade C11000 |

| Type | Compression | |

| Size | Various sizes available, typically | #2 AWG to 1000 kcmil |

| Temperature Rating | 75°C (167°F) | |

| Plating | Tin-plated | ASTM B545 |

| Conductor Type | Stranded or Solid | |

| Installation Method | Crimping | |

| Features | Barrel with inspection hole Embossed markings for size identification UL Listed RoHS compliant Suitable for use with copper conductors |

Features of Copper Lugs

Copper lugs offered by C-Fit Copper boast several key features:

- Conductivity: Copper lugs are highly conductive to electricity hence they are preferred in electrical wiring and power distribution systems.

- Corrosion Resistance: A copper lug also affords high level of corrosion protection to guarantee long-lasting performance, even under unfavorable conditions or in corrosive environment.

- Malleability: Copper is generally ductile in nature, this facilitates easy formation and fixing of copper lugs on cables or conductors to give firm and tight connection.

- High Temperature Tolerance: Copper lugs have a very high degree of heat resistance and therefore are very useful where heat resistance is required such as industrial applications or in vehicles.

- Compatibility: Copper lugs can easily be used on different cables of various sizes and thus it can connect to different systems and electrical components with ease.

- Convenience: Copper lugs may have additional installation design elements such as pre-drilled holes or crimping that enables the copper lugs to be easily fixed onto devices without involving complicated installation equipment.

Copper Cable Lugs Dimension, Size Table

A Copper Cable Lugs Dimension & Size Table gives a good specification of the size of the lug, the range of the conductor, the diameter of the stud hole, palm width, and thickness, which allows you to choose the correct lug when making electrical connections safely, efficiently, and reliably. It guarantees the best crimping, optimum conductivity, and electrical compliance in all the industrial and commercial activities.

| Cable Size | Stud Ø | A | B | C | D | E | F | G | H | L | Part # |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.5mm² | 5 | 1.8 | 3.7 | 7.5 | 8 | 5.2 | 1 | 4 | 5 | 16 | 1.5-5 |

| 1.5mm² | 6 | 1.8 | 3.7 | 7.5 | 10 | 6.5 | 0.8 | 4 | 6 | 16 | 1.5-6 |

| 2.5mm² | 4 | 2.4 | 4 | 8 | 8 | 4.2 | 1 | 4 | 5 | 18 | 2.5-4 |

| 2.5mm² | 5 | 2.4 | 4 | 8 | 10 | 5.2 | 0.8 | 5 | 6 | 20 | 2.5-5 |

| 2.5mm² | 6 | 2.4 | 4 | 8 | 10 | 6.5 | 0.8 | 5 | 6 | 20 | 2.5-6 |

| 2.5mm² | 8 | 2.4 | 4 | 8 | 11 | 8.4 | 0.7 | 6 | 9 | 26 | 2.5-8 |

| 4mm² | 5 | 3.1 | 4.8 | 9 | 10 | 5.2 | 1 | 5 | 6 | 20 | 4-5 |

| 4mm² | 6 | 3.1 | 4.8 | 9 | 10 | 6.5 | 1 | 5 | 6 | 20 | 4-6 |

| 4mm² | 8 | 3.1 | 4.8 | 9 | 12 | 8.4 | 0.8 | 6 | 9 | 26 | 4-8 |

| 6mm² | 5 | 3.8 | 5.5 | 10 | 10 | 5.2 | 1.2 | 5 | 6 | 23 | 6-5 |

| 6mm² | 6 | 3.8 | 5.5 | 10 | 12 | 6.5 | 1 | 6 | 9 | 27 | 6-6 |

| 6mm² | 8 | 3.8 | 5.5 | 10 | 12 | 8.4 | 1 | 6 | 9 | 28 | 6-8 |

| 6mm² | 10 | 3.8 | 5.5 | 10 | 15 | 10.2 | 0.8 | 8 | 11 | 32 | 6-10 |

| 10mm² | 5 | 4.7 | 7.1 | 10 | 12 | 5.2 | 1.8 | 6 | 7 | 27 | 10-5 |

| 10mm² | 6 | 4.7 | 7.1 | 10 | 12 | 6.5 | 1.8 | 6 | 7 | 27 | 10-6 |

| 10mm² | 8 | 4.7 | 7.1 | 10 | 14 | 8.4 | 1.6 | 7 | 8 | 29 | 10-8 |

| 10mm² | 10 | 4.7 | 7.1 | 10 | 15 | 10.5 | 1.5 | 8 | 10 | 32 | 10-10 |

| 10mm² | 12 | 4.7 | 7.1 | 10 | 18 | 13 | 1 | 10 | 12 | 38 | 10-12 |

| 16mm² | 6 | 5.5 | 7.9 | 19 | 11 | 6.5 | 2.4 | 7 | 9 | 39 | 16-6 |

| 16mm² | 8 | 5.5 | 7.9 | 19 | 14 | 8.4 | 1.7 | 7 | 9 | 39 | 16-8 |

| 16mm² | 10 | 5.5 | 7.9 | 19 | 16 | 10.5 | 1.5 | 8 | 10 | 41 | 16-10 |

| 16mm² | 12 | 5.5 | 7.9 | 19 | 18 | 13 | 1.2 | 10 | 13 | 46 | 16-12 |

| 25mm² | 6 | 7.1 | 9.5 | 21 | 13.5 | 6.5 | 2.4 | 7 | 9 | 41 | 25-6 |

| 25mm² | 8 | 7.1 | 9.5 | 21 | 13.5 | 8.4 | 2.4 | 7 | 9 | 41 | 25-8 |

| 25mm² | 10 | 7.1 | 9.5 | 21 | 16 | 10.5 | 1.9 | 9 | 10 | 44 | 25-10 |

| 25mm² | 12 | 7.1 | 9.5 | 21 | 18 | 13 | 1.6 | 10 | 13 | 48 | 25-12 |

| 35mm² | 6 | 8.4 | 11.5 | 21 | 16 | 6.5 | 3 | 9 | 10 | 45 | 35-6 |

| 35mm² | 8 | 8.4 | 11.5 | 21 | 16 | 8.4 | 3 | 9 | 10 | 45 | 35-8 |

| 35mm² | 10 | 8.4 | 11.5 | 21 | 18 | 10.5 | 2.6 | 9 | 10 | 45 | 35-10 |

| 35mm² | 12 | 8.4 | 11.5 | 22 | 20 | 13 | 2.2 | 11 | 13 | 51 | 35-12 |

| 50mm² | 6 | 9.5 | 12.8 | 22 | 18 | 6.5 | 3.3 | 8 | 10 | 46 | 50-6 |

| 50mm² | 8 | 9.5 | 12.8 | 22 | 18 | 8.4 | 3.3 | 8 | 10 | 46 | 50-8 |

| 50mm² | 10 | 9.5 | 12.8 | 22 | 18 | 10.5 | 3.3 | 8 | 10 | 46 | 50-10 |

| 50mm² | 12 | 9.5 | 12.8 | 22 | 21 | 13 | 2.7 | 11 | 13 | 54 | 50-12 |

| 70mm² | 6 | 11.3 | 14.6 | 22 | 21 | 6.5 | 3.5 | 11 | 13 | 54 | 70-6 |

| 70mm² | 8 | 11.3 | 14.6 | 24 | 21 | 8.4 | 3.5 | 11 | 13 | 54 | 70-8 |

| 70mm² | 10 | 11.3 | 14.6 | 24 | 21 | 10.5 | 3.5 | 11 | 13 | 54 | 70-10 |

| 70mm² | 12 | 11.3 | 14.6 | 24 | 21 | 13 | 3.5 | 11 | 13 | 54 | 70-12 |

| 70mm² | 16 | 11.3 | 14.6 | 24 | 26 | 17 | 3 | 14 | 13 | 61 | 70-16 |

| 95mm² | 8 | 13.5 | 17.4 | 27 | 25 | 8.4 | 4 | 12 | 14 | 60 | 95-8 |

| 95mm² | 10 | 13.5 | 17.4 | 27 | 25 | 10.5 | 4 | 12 | 14 | 60 | 95-10 |

| 95mm² | 12 | 13.5 | 17.4 | 27 | 25 | 13 | 4 | 12 | 14 | 60 | 95-12 |

| 95mm² | 16 | 13.5 | 17.4 | 27 | 25 | 17 | 3.5 | 14 | 16 | 64 | 95-16 |

| 120mm² | 8 | 15.6 | 20.6 | 30 | 30 | 8.4 | 5 | 12 | 14 | 64 | 120-8 |

| 120mm² | 10 | 15.6 | 20.6 | 30 | 30 | 10.5 | 5 | 12 | 14 | 64 | 120-10 |

| 120mm² | 12 | 15.6 | 20.6 | 30 | 30 | 13 | 5 | 12 | 14 | 64 | 120-12 |

| 120mm² | 16 | 15.6 | 20.6 | 30 | 30 | 17 | 5 | 16 | 16 | 72 | 120-16 |

| 150mm² | 10 | 16.7 | 22.2 | 30 | 32 | 10.5 | 5.8 | 16 | 16 | 71 | 150-10 |

| 150mm² | 12 | 16.7 | 22.2 | 32 | 32 | 13 | 5.8 | 18 | 18 | 75 | 150-12 |

| 150mm² | 16 | 16.7 | 22.2 | 30 | 32 | 17 | 5.8 | 18 | 18 | 75 | 150-16 |

| 185mm² | 10 | 18.4 | 24.2 | 32 | 36 | 10.5 | 5.8 |

Advantages and Disadvantages of Copper Lugs

Copper Lugs : Advantages

- Excellent Conductivity: Copper lugs provide great conductivity in transferring high voltage power while the insulating layer allows for safe connection without the risk of electrical shock.

- High Durability: It is fairly resistant to mechanical stress, as well as different kinds of environment impacts.

- Corrosion Resistance: Copper lugs are very durable and they do not rust easily, thus they are able to last for a very long time.

- Versatility: They are suitable for different wire sizes and are also available in different layouts, making them versatile.

- Easy Installation: Copper lugs are very convenient to use with the most common ways of connecting them being crimping or compression.

Copper Lugs : Disadvantages

- Cost: Copper lugs are pretty costly when compared with other options such as aluminum lugs.

- Weight: Nonetheless, copper lugs are relatively heavier than some of the above materials, which can complicate its application sometimes.

- Oxidation: Copper lugs can also corrode if they are not well protected, which can hinder their effectiveness.

- Limited Availability: For some parts of the world, copper lugs may not be as easily accessible as other materials may be.

- Risk of Theft: Copper lugs may be prone to theft in specific environments because of the elevated value of copper scrap.