Table of Contents

Copper Press Fittings Manufacturer, Stockist and Exporter in Italy

C-Fit Copper is a well-known manufacturer, stockist, and exporter of superior Copper press fitting in Italy. C-Fit Copper makes the products durable and of high performance to an international standard. We are dependable names in plumbing, HVAC, and gas installations at residential, commercial, and industrial levels in Italy. C-Fit Copper is known as a dependable supplier with lasting solution at an international level.

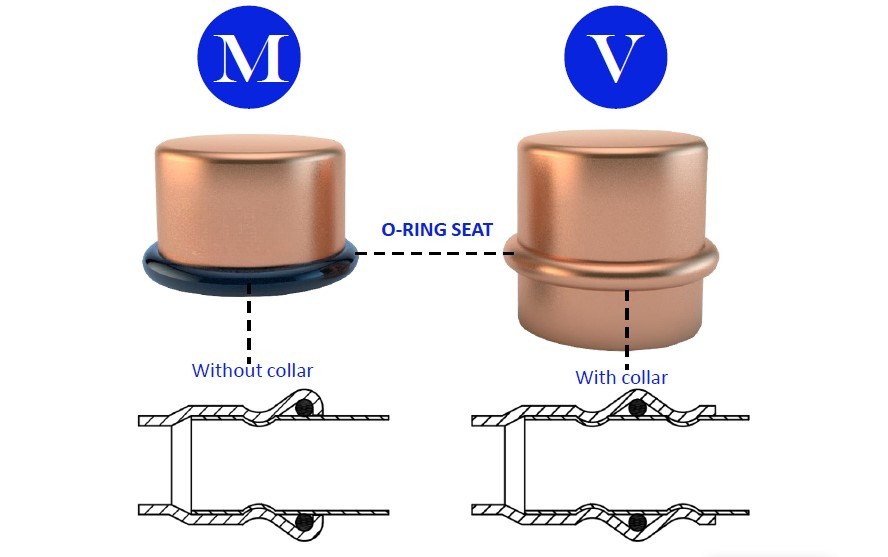

Copper Press Fittings – M & V Profile:

C-Fit Copper produces Copper press fittings in M and V profiles to fit a large variety of installation systems in Italy. These are high precision fitting and perfect sealing of plumbing, heating and gas pipeline projects. C-Fit Copper provides such profiles in different forms to offer industry specific requirements.

Difference Between M & V Profile:

There are differences between the M and V profile with regard to the designs of their press contours, which impacts the tools interface and the means of installation. C-Fit Copper provides both variants with the aim to be as flexible as possible and to serve professionals in Italy. The profiles offer a safe mechanical joint through sophisticated pressing technology.

Copper Press Fittings – M Profile:

M Profile Copper fittings manufactured by C-Fit Copper are recognizable by their three-point press shape; they are dependable copper press fittings suitable in water and heating applications. These are quite common in European-standard installations. The M Profile fittings provided by C-Fit Copper can be used with numerous press tools that are present in Italy.

Copper Press Fittings – V Profile:

C-Fit Copper V Profile fittings are unusually designed with four-point press to provide an additional grip and strength in such high-pressure systems. They are to be looked upon in gas and industrial piping systems in Italy. C-Fit Copper makes sure that its V Profile fittings comply with the major performance and safety requirements.

Coper Press Fitting Profiles Available – M & V :

C-Fit Copper supplies both press profiles, (M and V), to provide the flexibility of installation in various applications in Italy. These are profiles, which can be easily combined with regular press means. C-Fit Copper always has a steady stock of both variants to meet the instant project requirements.

Types of Copper Press Fittings:

C-Fit Copper provides wide Copper press fittings with variety of Copper press fittings such as elbows, tee, couplings, reducers, and end caps. Such fittings are hydraulically designed to be readily and safely installed without the use of flames and are suitable in plumbing, heating, ventilation and air conditioning (HVAC) and gas supply systems in Italy. The fittings used by C-Fit Copper are leak-free and secure, fast.

Copper Elbow Press Fittings:

C-Fit Copper make elbow press fittings to take copper pipelines because they alter the direction of the copper pipelines. The elbows come in different angles and assure smooth flow at confined locations. They find a lot of application in home water systems, air conditioning unit, and airline compressors in Italy.

Copper Tee Press Fittings:

C-Fit Copper copper tee press fittings is made to have the ability to branch pipelines into three-ways. They guarantee either balanced or decreased flow dispensation relying on application demands. In Italy, they are needed when there is a complex plumbing arrangement in the residential and industrial infrastructures.

Copper Coupling Press Fittings:

C-Fit Copper is the type of coupling press fitting that involves two straight lengths of copper pipe that are joined. They provide a durable and permanent seal that can be installed without the process of soldering hence installations are faster. In Italy they are most often found in water feeds and heating circuits, and cooling.

Copper Reducer Press Fittings:

C-Fit Copper makes copper reducer press fittings to join together a copper tube of one size to a second copper tube of a different size, at the same time ensuring only minimal system losses on the system. These reducers facilitate easy transition and fluid flow regulation along multi-size pipes to pipe systems. They are necessary in Italy in the case of adapting plumbing and HVAC systems.

Copper End Cap Press Fittings:

C-Fit Copper manufactures end cap press fittings that can be used to close-off the jobs at the end of copper pipes in a safe and permanent way. They are applied when testing the system, extending the system in future, or in the last-minute termination of the pipes. C-Fit Copper guarantees their application in all sort of building services in Italy.

Copper Press Fittings Specification:

C-Fit Copper press fittings are produced with high-quality grade copper that is highly corrosive and good in thermal conductivity. The fittings are in EN and ASTM standards in order to suit the demands of the Italian markets. All the fittings are examined on pressure integrity, mechanical strength and accuracy with dimensions. C-Fit Copper ensures that there is quality performance in water, gas and HVAC systems. These fittings have been designed with the capability of being installed fast and extinguishing the danger of flame thereby enhancing safety and efficiency at the site.

| Copper Press Fittings Specification: | |

|---|---|

| Material | High-Grade Copper (CW024A / DHP Copper) |

| Size Range | ½ inch to 4 inches |

| Profiles Available | M Profile and V Profile |

| Pressure Rating | Up to 16 bar (depending on size) |

| Temperature Range | -20°C to +110°C (varies by application) |

| Standards Compliance | EN 1254-7, WRAS Approved (if applicable) |

| Applications | Plumbing, HVAC, Compressed Air, Gas Systems |

Copper Press Fittings Properties:

C-fit Copper copper press fittings are renowned due to their great strength and ability to handle stress, great resistance to corrosion and high rate of thermal conduction. These fittings are also flexible in their structure and very resistant to pressure hence it is used in plumbing, HVAC and gas lines which are quite demanding. C-Fit Copper guarantees the fitness of every single fitting to a high quality, which would guarantee long service life and reliability. Such properties lead to safe, effective, and maintenance-free installations of Italy. C-Fit Copper press fittings perform well in harsh conditions unlike other products that require coating or covering with paint and hence they are a favorable option in the modern infrastructure.

- Durability: Copper press is durable and suitable in tough operating conditions, it can withstand significant mechanical loads. Their durability saves on maintenance and failure of the system especially on residential and industrial projects in Italy.

- Corrosion Resistance: C-Fit Copper fittings are made of copper which has anti-corrosion properties and therefore avoids the buildup, scaling and leaks. This characteristic guarantees an excellent working when it is used in water, gas, and heating systems in the Italy climate which is very diverse.

- Thermal Conductivity: Having high thermal conductivity, C-Fit Copper press fittings can be used to create an effective heat flow in HVAC and hot water systems. This will improve the performance and energy consumption of the buildings in Italy.

- Design Flexibility: C-Fit Copper contains vast fittings, which can be installed flexibly in complicated piping. Such flexibility makes on-site construction easy and helps to adopt the solution of each construction project in Italy.

- High Pressure Resistance: The C-Fit Copper press fittings are pressure-tested to handle high flow pressures thus they can be used both in low- and high-pressure systems. This plays a key role in establishing safety in gas supply and heating networks in all of Italy.

- Leak-Proof Performance: C-Fit Copper press fittings are designed to provide leak free joints provided they are used with suitable pressing tools. This will guarantee the sustainable integrity of systems and soldering or welding is unnecessary.

Copper Press Fittings : Size, Weight and Dimensions Table

C-Fit Copper offers Copper press fittings that are available in all the sizes and dimensions with respect to various project requirements in Italy. These contain options of residential small scale plumbing and largescale HVAC and gas installation. Being available in more than one size, you can fit them well, have a better control over its flow and occupy spaces. C-Fit Copper will provide proper sizing which has ensured the smooth integration of the systems as well as failures free operation.

| Size (Inches) | Outer Diameter (mm) | Standard Profile | Approx. Weight per Piece (grams) |

|---|---|---|---|

| ½” | 15 mm | M & V Profile | 45 – 60 g |

| ¾” | 22 mm | M & V Profile | 70 – 90 g |

| 1″ | 28 mm | M & V Profile | 110 – 130 g |

| 1¼” | 35 mm | M & V Profile | 160 – 200 g |

| 1½” | 42 mm | M & V Profile | 250 – 300 g |

| 2″ | 54 mm | M & V Profile | 370 – 450 g |

| 2½” | 67 mm | M & V Profile | 500 – 600 g |

| 3″ | 76.1 mm | M & V Profile | 700 – 850 g |

| 4″ | 108 mm | M & V Profile | 1200 – 1500 g |

Copper Press Fittings Chemical Composition:

C-Fit Copper press fittings are made by high purity copper alloy fittings which are up to global chemical standards. This composition guarantees resistance against oxidations, corrosions and degrading effects.

| Element | Composition (%) |

|---|---|

| Copper (Cu) | ≥ 99.90 |

| Phosphorus (P) | 0.015 – 0.040 |

| Others | ≤ 0.05 |

Copper Press Fittings Mechanical Properties:

C-Fit Copper press fittings have outstanding mechanical strength, toughness and pressure resistance, which are in line with performance needs of Italian plumbing and industrial systems.

| Copper Press Fittings Mechanical Properties | |

|---|---|

| Property | Value |

| Tensile Strength | 250 – 300 N/mm² |

| Elongation | ≥ 30% |

| Hardness | 40 – 80 HV |

| Density | 8.94 g/cm³ |

| Melting Point | 1083°C |

Copper Press Fitting in Italy : Advantages

C-Fit Copper, Copper press fittings are more advantageous as they are easily installed, and are durable in the long run, and require no flames to construct. They are good during the construction of a new building and during a retrofit since they reduce on-site labor time, and make the site safer. C-Fit Copper guarantees quality materials in terms of leak-free, corrosion-resistance performance. They use profiles M and V press which gives them compatibility with different models of system designs.

- Fast and Easy Installation: C-Fit Copper press fittings do not require soldering or welding making them short in installation time and labor cost. This is particularly a good incentive in big or time sensitive projects in Italy.

- Flame-free and Safe: C-Fit Copper press system maximizes safety at the job site because there are no open flames, that is why they can be used in limited space or hazardous places like hospitals or factories.

- Leak-Proof Connection: The accuracy of the design and the quality of material provide a safe and mutually sustaining seal that lowers the likelihood of leakage reducing maintenance and upgrading the system reliability.

- Corrosion resistance and pressure resistance: C-Fit Copper press fittings have a good performance in corrosion environment and high pressure, with high integrity, so that continuous working can be maintained.

- Versatile Application: The fittings fit various applications such as HVAC, plumbing, and gas systems and are very flexible and convenient in any structure of installation.

Copper Press Fittings in Italy : Applications

C-Fit Copper press fittings are a common thing in Italy in any given industry, whether it is a complex industrial HVAC and fire suppression product or domestic water supply and gas pipes. They are reliable, easy to use and comply with safety standards, which makes them a reliable brand to use. C-Fit Copper complies with both local and international standards on residential, commercial and infrastructure products.

Copper Press Fittings Industrial Uses:

- HVAC Systems: C-Fit Copper press fittings can deliver strong and safe connections in chilled and heated water circulation systems in HVAC systems in industries, and that is why they are energy-efficient and durable.

- Fire Protection Systems: Such fittings are most suitable in fire suppression piping because the process of installing the fittings is both flames free and follows safety regulations, as it is highly pressure resistant.

- Compressed Air Systems: C-Fit Copper press fittings are pressure maintaining on compressed air systems around manufacturing plants and ensure their maintenance by stopping leaks.

- Industrial Gas Lines: C-Fit Copper is utilized in factories and processing units where the fittings can withstand the pressure and exposure to the chemical loading of a typical industrial gas distribution system.

- District Heating Networks: C-Fit Copper provides press fittings for big scale distribution of hot water in municipal and industrial heating operations, where continuity in heat transfer as well as reliability is guaranteed.

Copper Press Fittings General Uses:

- Residential Plumbing: C-Fit Copper press fittings make quick, clean connections using left handed, right handed and squared off press fittings suitable for water supply lines to your house hold. The full process does not require soldering in defining how to form long life leak free connections.

- Domestic Heating Systems: C-Fit Copper fittings work with radiator and warm water systems to enhance to flow of heat and easy re-fitting homes through-out Italy.

- Commercial Buildings: C-Fit Copper press fittings are commonly used in the buildings of today where plumbing, heating and cooling networks are concerned, since they are reliable and easy to maintain.

- Distribution of Gas in Houses: C-Fit Copper fitting components are utilized in the domestic gas type pipelines, which provides tamper risk-free, gas safe joints capable of exceeding high gas safety requirements.

- Renovation Projects: C-Fit Copper press fittings are ideal in any plumbing or heating remodeling where an older building has plumbing and heating systems that need to be replaced, upgraded or supplemented.