Table of Contents

Copper Press Fittings Manufacturer, Stockist and Exporter in USA

As a leading manufacturer and exporter C-Fit Copper maintains top positions in producing premium-grade Copper press fittings for the USA market. The Copper press fittings that we produce have earned universal market trust because they deliver leak-free operation and extended service life. The product quality testing procedures at C-Fit Copper conform with strict specifications for applications throughout the entire territory of USA.

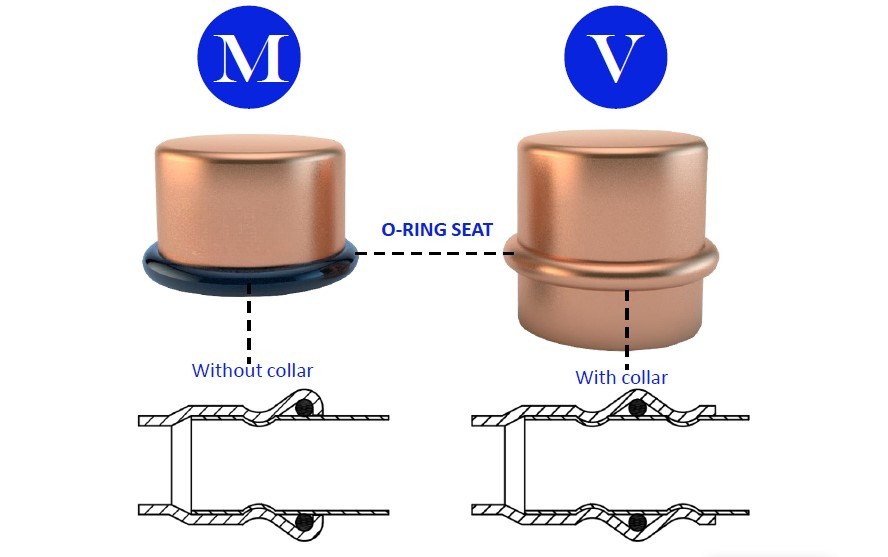

Copper Press Fittings – M & V Profile:

Both M and V profiles exist within the product range of C-Fit Copper’s Copper press fittings which meet different system specifications. These fittings provide quick installation characteristics together with lasting seal quality. The C-Fit Copper brand delivers its products to meet numerous performance requirements throughout every setting from industrial to residential uses in USA.

Difference Between M & V Profile:

M and V profiles feature different grooves together with separate pressing equipment. The groove in M profile is deeply rounded compared to the smoother but less pronounced V profile structure. C-Fit Copper supplies its M & V profiles to US clients according to their specifications and preferred designs.

Copper Press Fittings – M Profile:

The M Profile Copper press fittings produced by C-Fit Copper have deep grooves that follow a rounded shape. Such fittings maintain a powerful mechanical joint that enables their extensive use in water systems as well as HVAC applications and industrial environments. M profile fittings operate with M-profile pressing jaws and power the majority of USA copper fitting installations.

Copper Press Fittings – V Profile:

The V Profile Copper press fittings produced by C-Fit Copper maintain a shallow and flat groove shape for their design. The V-profile pressing tools specifically selected in certain regional standardization areas enable their use.

The V-profile tools dominate the gas and plumbing sectors across USA making these fittings the optimal choice.

Coper Press Fitting Profiles Available – M & V :

C-Fit Copper offers M and V press profiles at their facility to serve different industry requirements in addition to providing tool compatibility for the USA market. C-Fit Copper fittings provide exceptional durability and best possible performance for both M profile and V profile system applications. Press profiles demonstrate flexibility which results in efficient and reliable installation procedures.

Types of Copper Press Fittings:

C-Fit Copper produces Copper press fittings in various sizes which work for plumbing together with HVAC and gas systems across the USA market. The developed fittings enable fast and secure connections which eliminate the need for soldering during installation. At C-Fit Copper customers can select from elbows and tees and couplings as well as reducers in addition to end caps that showcase outstanding precision and strength features.

Copper Elbow Press Fittings:

C-Fit Copper produces Copper Elbow Press Fittings which enable piping systems to redirect their water flow path. The product provides a firm bend design with no leaks that works well for compact plumbing and HVAC system applications.

Copper Tee Press Fittings:

C-Fit Copper produces Copper Tee Press Fittings as an accurate solution for creating pipeline branches. The press-fit piping system relies on these fittings to establish secure three-way connections that work for both equal flow and partial flow purposes.

Copper Coupling Press Fittings:

C-Fit Copper provides Copper Coupling Press Fittings as pipe-connecting components that join parallel pipes through their straight sections. Copper couplings provide a stainless internal surface and dependable version joint connection which can broaden pipeline networks.

Copper Reducer Press Fittings:

C-Fit Copper provides Copper Reducer Press Fittings for linking pipes with different diameter measurements. The fittings deliver controlled pressure and fluid flow during dealings with different diameter changes across water and gas and HVAC systems.

Copper End Cap Press Fittings:

C-Fit Copper produces Copper End Cap Press Fittings that create dependable seals for pipes ends. These end caps find their most useful application when closing systems for pressure testing or permanent system terminations.

Copper Press Fittings Specification:

C-Fit Copper produces Copper press fittings which meet all international standards needed to operate successfully within the United States market. The exact fittings receive specific engineering to ensure low leakages during press-connect operations. Manufactured by C-Fit Copper the product maintains uniform wall composition as it delivers precise dimensions alongside smooth surface quality. A set of precise specifications confirms that C-Fit Copper provides reliable performance to contractors and engineering professionals.

| Material | High-Grade Copper (CW024A / DHP Copper) |

| Size Range | ½ inch to 4 inches |

| Profiles Available | M Profile and V Profile |

| Pressure Rating | Up to 16 bar (depending on size) |

| Temperature Range | -20°C to +110°C (varies by application) |

| Standards Compliance | EN 1254-7, WRAS Approved (if applicable) |

| Applications | Plumbing, HVAC, Compressed Air, Gas Systems |

Copper Press Fittings Properties:

The Copper press fittings produced by C-Fit Copper unite both mechanical durability with reliable performance. The materials have outstanding durability alongside corrosion protection and show resistance to thermal and pressure changes. The combination of material attributes enables C-Fit Copper to serve across various residential and commercial and industrial needs. The C-Fit Copper company delivers dedicated performance under challenging applications for each fitting they produce. These components possess the capability to conduct heat efficiently because of their combined thermal conductivity and flexibility properties.

- Durability: C-Fit Copper press fittings display a lifespan of multiple decades without expecting any necessity for substitute components. High-pressure along with high-temperature settings do not impact this material since it resists ongoing degradation which enables extended system durability.

- Corrosion Resistance: C-Fit Copper applies copper material that naturally withstands corrosion and rust thus becoming perfect for application in water and gas and air-based systems. The material purity of flowing media in pipes remains high for extended periods due to this system.

- Thermal Conductivity: The C-Fit Copper fittings function excellently as heat conductors which leads to their efficient usage in both hot water systems and HVAC pipeline networks. The materials transfer heat efficiently while maintaining structural performance of their components at all times.

- Flexibility: The C-Fit Copper copper press fittings give users the ability to build flexible systems. The press-fit installation feature makes it possible for users to modify their system onsite without needing soldering or welding.

- Pressure Resistance: These connections underwent specialized development to create secure sealing performance at high pressure values. At C-Fit Copper they subject every fitting to tests which prove connection reliability during static and dynamic operations.

- Leak-Free Performance: Technologies in precise manufacturing and press-fit operation make the joints completely leakproof. C-Fit Copper creates dependable solid connections which work reliably in inaccessible positions together with those located above floors.

Copper Press Fittings : Size, Weight and Dimensions Table

C-Fit Copper provides Copper press fittings suitable for all plumbing and HVAC project requirements at every scale in the United States. Authorized dealers of C-Fit Copper provide fittings designed precisely for small residential projects and large commercial systems alike. The varied sizes fit both upcoming systems and those already in place. The mechanical performance of C-Fit Copper products depends upon their precise dimensional specifications which lead to better system performance.

| Size (Inches) | Outer Diameter (mm) | Standard Profile | Approx. Weight per Piece (grams) |

|---|---|---|---|

| ½” | 15 mm | M & V Profile | 45 – 60 g |

| ¾” | 22 mm | M & V Profile | 70 – 90 g |

| 1″ | 28 mm | M & V Profile | 110 – 130 g |

| 1¼” | 35 mm | M & V Profile | 160 – 200 g |

| 1½” | 42 mm | M & V Profile | 250 – 300 g |

| 2″ | 54 mm | M & V Profile | 370 – 450 g |

| 2½” | 67 mm | M & V Profile | 500 – 600 g |

| 3″ | 76.1 mm | M & V Profile | 700 – 850 g |

| 4″ | 108 mm | M & V Profile | 1200 – 1500 g |

Copper Press Fittings Chemical Composition:

High-purity copper forms the manufacturing basis for C-Fit Copper press fittings which result in excellent performance together with superior corrosion resistance and mechanical strength in all USA applications.

| Element | Composition (%) |

|---|---|

| Copper (Cu) | ≥ 99.90 |

| Phosphorus (P) | 0.015 – 0.040 |

| Others | ≤ 0.05 |

Copper Press Fittings Mechanical Properties:

The mechanical properties of C-Fit Copper press fittings include high tensile strength and ductility and hardness which makes them ideal for challenging environments.

| Property | Value |

|---|---|

| Tensile Strength | 250 – 300 N/mm² |

| Elongation | ≥ 30% |

| Hardness | 40 – 80 HV |

| Density | 8.94 g/cm³ |

| Melting Point | 1083°C |

Copper Press Fitting : Advantages

C-Fit Copper press fittings operate efficiently because they use easy installation methods without requiring soldering or welding. Through its press-fit operation the installation times shorten substantially without compromising the connection durability. These fittings prove to be more cost-effective for extended periods because they need minimal maintenance and achieve long service life. Members of industry select C-Fit Copper as their prime choice because of their uniform quality standards and broad size portfolio.

- Quick & Easy Installation: The press-fit design technique enables flashing installations at half the duration of standard protocol.

- No Flame Required: The system’s safety improves because soldering as well as welding operations become unnecessary for installation purposes.

- Permanent Leak-Proof Joints: The C-Fit Copper technology produces joints which offer lifetime resistance for system peripherals.

- Reduced Downtime: The fast installation process lets systems start up rapidly without requiring prolonged worker downtime.

- Environmentally Friendly: The fittings consist of recyclable copper material which benefits sustainable construction methods.

Copper Press Fittings : Uses

C-Fit Copper press fittings find extensive use throughout USA for building and maintaining plumbing systems and heating and cooling and gas distribution networks. C-Fit Copper press fittings serve both residential buildings and large commercial as well as industrial facilities because of their established safety standards and durability. The entire product range of C-Fit Copper fulfills stringent requirements needed for complex infrastructure development.

Industrial Uses:

- HVAC Systems: The C-Fit Copper press fittings work within heating, ventilation and air conditioning systems because they possess superior performance attributes for pressure handling and thermal conductivity.

- Compressed Air Lines: Manufacturers utilize Copper press fittings by C-Fit Copper for their compressed air pipeline applications because they provide reliable joints that maintain corrosion resistance and excel at pressure resistance while preventing leaks.

- Medical Gas Systems: The press fitting products from C-Fit Copper provide essential solutions for hospital and healthcare facilities by ensuring leak-free medical gas pipelines with their pure material composition for safety obligations.

- Fire Protection Systems: Active fire safety systems in public spaces utilize copper press fittings obtained from C-Fit Copper. These products thrive under emergencies due to their extended lifespan and fast installation procedures which are vital for critical response infrastructures.

General Uses:

- Residential Plumbing: C-Fit Copper presents its customers with dependable Copper press fittings to build leak-resistant water supply lines that feature effortless maintenance measures.

- Commercial Buildings: Hot and cold water system installations in office complexes shopping centers along with hotels depend on C-Fit Copper press fittings because of their clean installation process and durable long-term performance.

- Gas Distribution: The natural gas and LPG systems depend on C-Fit Copper precision fittings to establish safe connections which do not require soldering.

- Renovation Projects: C-Fit Copper press fittings make it possible to perform fast modifications in retrofit and renovation work because they introduce changes without touching existing infrastructure structures. This approach minimizes disruptions and prevents production stoppages.