Table of Contents

Copper Press Fittings Manufacturer, Stockist and Supplier in India

As the leading manufacturer, stockist, and supplier of high-quality copper press fittings within India stands C-Fit Copper. C-Fit Copper produces fittings which maintain durability and precision for demanding applications through their strong commitment to such features. The plumbing HVAC and gas distribution sectors use our copper press fittings as their trusted choice. The company C-Fit Copper maintains its position as an industry leader through continuous innovation of premium products.

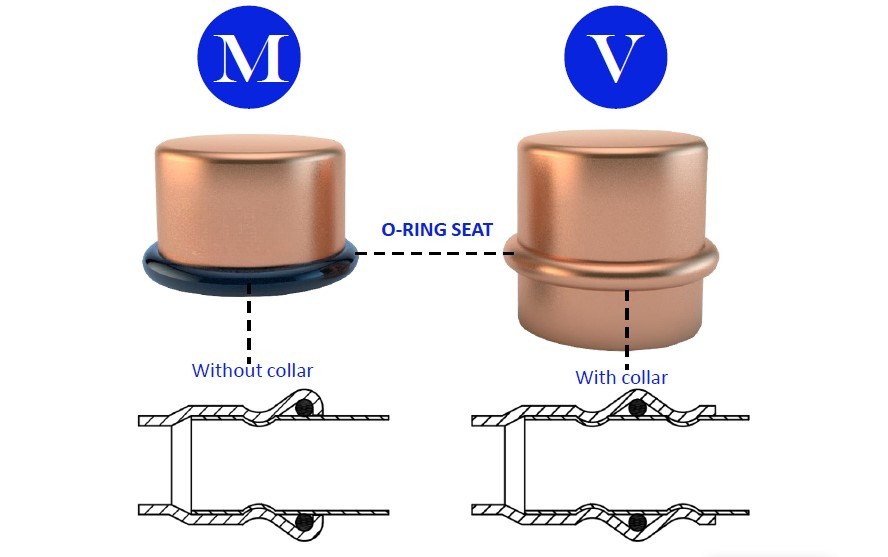

Copper Press Fittings – M & V Profile:

C-Fit Copper produces copper press fittings which provide rapid secure installation without requiring flames. These fittings have dual M and V profiles which make them suitable for modern plumbing alongside industrial piping applications because they support different tool requirements. C-Fit Copper maintains equal standards of quality and performance among different profile types.

Difference Between M & V Profile:

The C-Fit Copper manufacturing company produces M and V profile copper press fittings that correspond to various installation standards in different regions. M Profile and V Profile function in press-fit piping applications yet show distinct variations in form and installation characteristics as well as their related tools.

Copper Press Fittings – M Profile:

M profile copper fitting inserts exhibit a deep circular pressing configuration. The fittings maintain a three-point press design where one pressing point exists at both ends and one in the middle to deliver leak-proof results through strong secure connections. This profile serves as the standard choice for both European and multiple international markets. The C-Fit Copper M Profile fittings work reliably with many of the standard M-profile press tools in the market.

Copper Press Fittings – V Profile:

The pressing contour of V Profile fittings has a V-shaped design with a narrow surface. Applications of the press should happen in two positions where tight and efficient connections form especially during installation when space is limited. V Profile fittings are chosen as the standard connector in particular geographical areas. The manufacturing process at C-Fit Copper produces V Profile fittings which match perfectly with modern top-brand press tools.

Coper Press Fitting Profiles Available – M & V :

C-Fit Copper provides copper press fittings in M and V profiles which enable compatibility with different pressing tools during installation. C-Fit Copper provides M and V profile copper fittings because M profile features curved press contours which can be found throughout European markets while V profile features angled design specifications for selected system installations. Dual sealing capabilities exist within the copper profiles which demonstrate excellent durability features when implemented correctly along with suitable processing devices.

Types of Copper Press Fittings:

C-Fit Copper provides an exhaustive collection of press fittings that enable swift and airtight bond formation within plumbing and heating ventilation and air conditioning systems and gas networks. The available fittings from our manufacturing come in several options which adapt to diverse pipeline designs and structural needs. The installation process benefits from C-Fit Copper products while these products ensure superior system integrity for residential spaces and commercial areas and industrial installations. The exact manufacturing methods produce fittings which accommodate multiple types of piping setups.

Copper Elbow Press Fittings:

C-Fit Copper offers copper elbow press fittings which alter pipeline flow direction in standardized 90° and 45° positions. Because of their compact dimensions these fittings find their perfect application in tight spaces while maintaining unimpeded water and gas as well as HVAC directional movement.

Copper Tee Press Fittings:

C-Fit Copper produces copper tee press fittings which divide or unite fluid flow distribution across three different directions. Within plumbing and air-conditioning frameworks these fittings perform branch connections where they deliver powerful leak-free joints.

Copper Coupling Press Fittings:

C-Fit Copper manufactures copper coupling press fittings to join together two sections of straight copper tubing. The fittings provide reliable pipeline extension and replacement capabilities for maintenance of continuous performance.

Copper Reducer Press Fittings:

C-Fit Copper manufactures copper reducer fittings through their press technology for joining pipes of varying diameters. The priority fittings work in systems for flow reduction or size transitions because they help maintain system performance.

Copper End Cap Press Fittings:

C-Fit Copper provides copper end cap press fittings for safety termination of pipe ends. The fittings serve as a perfect solution to block off pipeline sections that are unused and they provide future extension points or temporary shut-offs frequently.

Copper Press Fittings Specification:

The precision-made copper press fittings from C-Fit Copper match international standards for plumbing and HVAC system requirements. Premium-grade copper serves as the material for manufacturing these fittings that exist in M and V press profiles. The dimensional accuracy and sealing properties together with extended service life of C-Fit Copper ensure its excellence. The fittings work under different combinations of temperature levels and pressure requirements.

| Copper Press Fittings Specification | |

|---|---|

| Material | High-Grade Copper (CW024A / DHP Copper) |

| Size Range | ½ inch to 4 inches |

| Profiles Available | M Profile and V Profile |

| Pressure Rating | Up to 16 bar (depending on size) |

| Temperature Range | -20°C to +110°C (varies by application) |

| Standards Compliance | EN 1254-7, WRAS Approved (if applicable) |

| Applications | Plumbing, HVAC, Compressed Air, Gas Systems |

Copper Press Fittings Properties:

The product properties from C-Fit copper press fittings make them optimal for contemporary piping techniques. These fittings stand out due to their long-term reliability in demanding conditions brought about by their high durability and corrosion-resistant properties. The copper elements perform efficient heat distribution through their natural thermal properties alongside their natural flexibility that helps installation efficiency. These Copper Press Fittings operate under extreme pressure conditions and temperature changes thus playing a vital role in every residential and industrial building as well as commercial spaces.

- Durability: The C-Fit Copper copper press fittings demonstrate exceptional durability because they provide exceptional mechanical strength together with outstanding wear resistance. These fittings have a long operating life which lowers system maintenance requirements while guaranteeing performance reliability in critical applications.

- Corrosion Resistance: The production of C-Fit Copper fittings through high-quality copper materials allows them to resist corrosion naturally. Their corrosion resistance properties make C-Fit Copper press fittings suitable for delivery of safe drinking water and distribution of gas to residential properties.

- Thermal Conductivity: The heat conduction ability of copper within C-Fit Copper press fittings optimizes their performance in HVAC systems along with hot water networks. Their excellent thermal conductivity property both increases system operational performance while reducing power consumption.

- Flexibility in Design: C-Fit Copper provides various fitting types together with multiple size options that enhance user freedom when designing piping layouts. The adjustable design of C-Fit Copper press fittings makes buildings installation more straightforward and enables project-specific adjustments in complicated projects.

- Pressure Resistance: C-Fit Copper fittings have successfully passed tests for performing under high-pressure conditions. A product combination of precise structure with pressure-resistant connections safeguards security levels even when systems experience high-demand usage.

- Easy and Fast Installation: The installation time reduces significantly through press-to-fit technology and M and V profile compatibility of C-Fit Copper fittings. These fittings remove the requirement for soldering operations thus cutting down site risks along with labor expenses.

Copper Press Fittings : Size, Weight and Dimensions Table

C-Fit Copper supplies copper press fittings which come in diverse dimensions and sizes to support various system applications. As part of our product offering we provide tubing fittings spanning from ½ inch to 4 inches to suit residential through industrial application scenarios. The wide selection of sizes ensures perfect fluid movement together with proper integration between different pressure limits. The precise system design for project requirements is possible because C-Fit Copper offers a variety of size options.

| Size (Inches) | Outer Diameter (mm) | Standard Profile | Approx. Weight per Piece (grams) |

|---|---|---|---|

| ½” | 15 mm | M & V Profile | 45 – 60 g |

| ¾” | 22 mm | M & V Profile | 70 – 90 g |

| 1″ | 28 mm | M & V Profile | 110 – 130 g |

| 1¼” | 35 mm | M & V Profile | 160 – 200 g |

| 1½” | 42 mm | M & V Profile | 250 – 300 g |

| 2″ | 54 mm | M & V Profile | 370 – 450 g |

| 2½” | 67 mm | M & V Profile | 500 – 600 g |

| 3″ | 76.1 mm | M & V Profile | 700 – 850 g |

| 4″ | 108 mm | M & V Profile | 1200 – 1500 g |

Copper Press Fittings Chemical Composition:

C-Fit Copper implements premium copper materials for manufacturing their press fittings which produce excellent resistance to corrosion while maintaining high purity levels. International safety standards determine the chemical content which guarantees operational safety together with performance quality.

| Element | Composition (%) |

|---|---|

| Copper (Cu) | ≥ 99.90 |

| Phosphorus (P) | 0.015 – 0.040 |

| Others | ≤ 0.05 |

Copper Press Fittings Mechanical Properties:

C-Fit Copper fittings maintain their mechanical properties with superior durability features along with outstanding reliability characteristics for operational longevity.

| Property | Value |

|---|---|

| Tensile Strength | 250 – 300 N/mm² |

| Elongation | ≥ 30% |

| Hardness | 40 – 80 HV |

| Density | 8.94 g/cm³ |

| Melting Point | 1083°C |

Copper Press Fitting : Advantages

The C-Fit Copper copper press fittings feature numerous benefits which make them the preferred choice for safe and quick and dependable installation applications. Our fittings provide professionals in multiple sectors with the advantage of time efficiency and leak-proof operation as their preferred connection solution. These press fittings demonstrate environmental friendliness while retaining durability and they work with both hot and cold systems which fulfills current infrastructure demands.

- Flame-Free Installation: Numerous advantages arise from the lack of soldering or welding requirements because they create safer installations that require less time to complete.

- Leak-Proof Connections: The secure press technology creates tight enduring seals capable of stopping leaks.

- Reduced Labor Costs: Presence of simple installation mechanisms shortens project installation periods and lowers work costs.

- Versatility: Installation requirements for potable water and HVAC systems, compressed air and gas systems make this product appropriate.

- Reliable Performance: High levels of heat and pressure change do not affect the product’s operational quality.

Copper Press Fittings : Uses

C-Fit Copper copper press fittings serve multiple applications which include industrial HVAC systems together with residential plumbing solutions. The fittings present user-friendly installation alongside reliable sealing ability which enables contractors to work on new builds as well as retrofit efforts. C-Fit Copper manufacturing ensures every product delivers all three elements of efficient operation along with safety protocols and system longevity.

Copper Press Fittings : Industrial Uses

- HVAC Systems: The commercial and industrial HVAC networks utilize C-Fit Copper press fittings for distributing the flow of fluid or refrigerant through high-pressure environments.

- Fire Protection Systems: C-Fit Copper fittings provide fast installation and leakproof operations in fire sprinkler systems since these capabilities are vital to emergency preparedness and safety regulations.

- Compressed Air Systems: The C-Fit Copper fitting system enhances industrial compressed air network performance through its exceptional pressure resistance performance together with leak-resistant characteristics.

- Process Cooling & Heating: Industrial temperature control systems use C-Fit Copper fittings because they deliver superior heat transfer performance at high temperatures while withstanding corrosive conditions.

Copper Press Fittings : General Uses

- Residential Plumbing: C-Fit Copper press fittings serve the home water supply industry because they present a clean appearance and allow quick installation without using fire.

- Commercial Buildings: The C-Fit Copper press fittings help build planners complete rapid and secure water line installations in broad building complexes without damaging ongoing operation.

- Hot & Cold Water Systems: C-Fit Copper press fittings maintain optimum performance and durability for hot and cold water distribution systems since they resist material deterioration.

- Gas Piping Systems: C-Fit Copper press fittings deliver complete safety during gas line operations when installed to connect piping in kitchen gas systems or heating systems through their secure and airtight fittings.