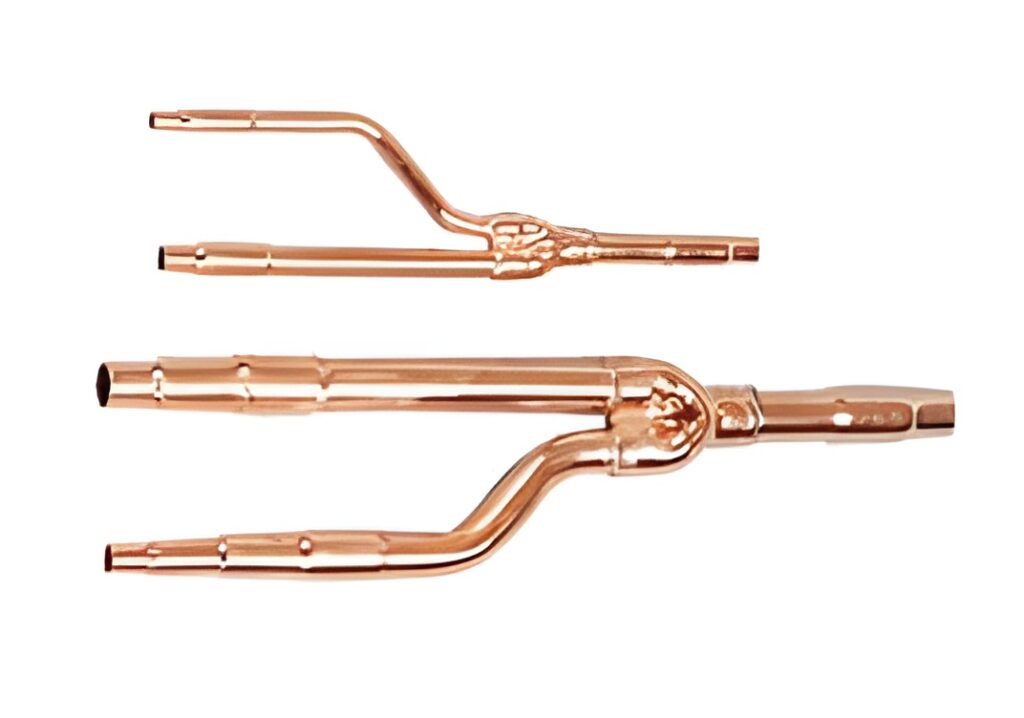

C-Fit Copper stands as a premier U.S. producer and exporter of premium Copper Y-bends that meet industry requirements through its advanced precision manufacturing. The dedication to creating products with extended lifespan and immunity against corrosion at C-Fit Copper delivers reliable outcomes for customers. The company uses its advanced manufacturing techniques to support global performance standards which drives excellent results in HVAC and plumbing solutions as well as industrial requirements. ELiquid8Products makes Copper Y-bends for C-Fit Copper specifically built to combine seamlessly with intricate piping systems for extended operational excellence. C-Fit Copper maintains itself as a dependable industry leader by distributing premium copper fittings worldwide.

Table of Contents

Copper Y-bend in USA : Properties

Y-bends manufactured by C-Fit Copper demonstrate crucial traits that make them vital for industrial operations and commercial needs throughout the United States. These fittings remain usable for long periods of time thus minimizing both maintenance fees and system breakdowns. These fittings maintain protection against environmental degradation due to corrosion which makes them suitable for HVAC and plumbing installations. Excellent thermal conductivity in C-Fit Copper Y-bends improves both cooling and heating system energy efficiency. The flexible nature of C-Fit Copper Y-bends enables straightforward installation at locations with restricted physical access. These pipes demonstrate high mechanical strength that allows maximum operational safety in applications where stringent pressure requirements exist including medical gas delivery systems and refrigerants.

- Durability : Structurally strong Copper Y-bends manufactured by C-Fit Copper exhibit powerful tensile properties with additional resistance against wear. The strong construction of these fittings endures for extended periods in industrial programs combined with residential applications.

- Corrosion Resistance : C-Fit Copper fittings display resistance to rust and chemicals while operating effectively in demanding environments thus extending system lifespan in plumbing and HVAC applications.

- Thermal Conductivity : The heat transfer capabilities of Copper Y-bends excel in refrigeration systems and air conditioning applications while also serving heating applications.

- Flexibility : C-Fit Copper Y-bends feature installation-friendly features which enables their use in intricate piping structures resulting in no damage to structural elements.

- Pressure Resistance : The fittings endure high-pressure functions because they offer elevated safety levels combined with reliability in vital applications which involve gas pipelines and refrigeration units.

- Eco-Friendly : Copper Y-bends demonstrate full recyclability within construction and industrial settings which helps builders advance sustainable development while supporting eco-friendly operations.

- Leak-Proof Design : The exact engineering of C-Fit Copper Y-bends secures leak-proof connections that reduce both maintenance expenses and system performance losses.

Copper Y-Bend in USA : Specification

C-Fit Copper executes expert copper manufacturing of Y-bends which uses top-quality copper materials for increased performance and extended durability. These industrial products fulfill international requirements thanks to their robust combination of performance attributes that span multiple chemical and mechanical criteria for diverse applications. A combination of precise dimensions combined with superior craftsmanship enables these fittings to serve as a dependable solution for plumbing and HVAC systems as well as gas pipeline applications throughout the USA.

| Copper Y Bend | Specification |

| Standard: | JIS B2313 Fitting, ANSI B16.9 Fitting, ANSI B16.28 Fitting, MSS-SP-43 Type A Fitting, MSS-SP-43 Type B Fitting, JIS B2312 Fitting, MSS-SP-43 Type b Fitting |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Application: | Chemical Industry Water Pipeline Industry Nuclear Power Plant Natural Gas Industry Fabrication Industry Oil And Gas Industry |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Fitting Machining Equipment: | Electric beveling machine, Press machine, Bending machine, Pushing Machine, Sand-blasting machine etc. |

Copper Y-Bend in USA : Size and Dimensions

The product range of C-Fit Copper offers Copper Y-bends with different dimensions and sizes that satisfy selective needs across industries worldwide in the United States. Multiple size choices within C-Fit Copper Y-bends enable hassle-free installation across residential homes and commercial buildings and industrial facilities. The system’s adaptable nature allows clients to obtain exact project solutions that improve both performance dimensions and efficiency standards.

| Nominal Size (inches) | Outside Diameter (OD) (inches) | Center-to-End Dimension (inches) | Branch Outlet Diameter (inches) |

|---|---|---|---|

| 1/2 | 0.625 | 1.25 | 0.625 |

| 3/4 | 0.875 | 1.50 | 0.875 |

| 1 | 1.125 | 1.75 | 1.125 |

| 1 1/4 | 1.375 | 2.00 | 1.375 |

| 1 1/2 | 1.625 | 2.25 | 1.625 |

| 2 | 2.125 | 2.75 | 2.125 |

| 2 1/2 | 2.625 | 3.25 | 2.625 |

| 3 | 3.125 | 3.75 | 3.125 |

| 4 | 4.125 | 4.75 | 4.125 |

Copper Y-Bend in USA : Chemical Composition

The manufacturers of C-Fit Copper Y-bends utilize high-purity copper materials which receive controlled chemical composition tests for maximizing resistance to corrosion and mechanical operation. The designed chemical compositions optimize the fittings’ life span and performance reliability across diverse applications.

| Element | Copper | Iron | Phosphorous | Zinc |

| Grade | 98.5 min | 0.8-1.2 | 0.01-0.04 | 0.2 |

|---|

Copper Y-Bend in USA : Mechanical Properties

The mechanical properties of C-Fit Copper’s Copper Y-bends include strong tensile strength and excellent yield strength and improved ductility attributes which support high-pressure alongside temperature-sensitive operations.

| Copper Y Bend | Yield Strength (0.2%Offset) | Tensile Strength | Elongation | Machinability |

| Grade | 69.0 – 345 MPa | 221 – 379 MPa | 45% | 20% |

Copper Y-Bend in USA : Pressure Rating

The designers of C-Fit Copper Y-bends created these components specifically for demanding high-pressure conditions to ensure both safety and reliability. Strong building quality allows these elements to maintain their shape regardless of what extreme pressure situations might bring.

| Nominal Size (inches) | Type K (psi) | Type L (psi) | Type M (psi) |

|---|---|---|---|

| 1/2 | 1,200 | 1,000 | 850 |

| 3/4 | 1,000 | 850 | 700 |

| 1 | 900 | 750 | 600 |

| 1 1/4 | 800 | 650 | 500 |

| 1 1/2 | 700 | 550 | 450 |

| 2 | 600 | 450 | 400 |

| 2 1/2 | 500 | 400 | 350 |

| 3 | 450 | 350 | 300 |

| 4 | 400 | 300 | 250 |

Copper Y-Bend in USA : Advantages

C-Fit Copper Y-bends provide numerous advantages which drive their widespread usage among industries throughout the USA.

- Exceptional Durability : The premium copper material provides a bend that retains resilience for extended use requirements as well as low upkeep needs.

- Corrosion-Resistant : These fittings prove their worth in demanding operational settings such as HVAC systems plumbing lines and industrial equipment.

- High Thermal Efficiency : The system operating efficiency improves in heating cooling and refrigeration applications.

- Flexible Installation : Universal fitment capabilities simplify various piping designs which cuts down both setup periods and installation challenges.

- Eco-Friendly Material : The 100% recyclable copper material stands as an important contribution toward creating sustainable construction projects.

- Leak-Proof Performance : Through precise engineering all connections maintain tight fitting which leads to minimal fluid leakage.

Copper Y-Bend in USA : Applications

C-Fit Copper distributes its Copper Y-bends throughout the United States and USA-based diverse industries utilize them in industrial and residential construction projects. The functional purpose of these fittings strengthens fluid and gas movement efficiency across HVAC systems and refrigeration units and medical gas pipelines and commercial plumbing applications. Critical infrastructure projects depend heavily on these components because of their exceptional reliability and durability characteristics.

Industrial Applications

- HVAC and Refrigeration Systems : The energy performance of heating and cooling units achieves better efficiency through improved refrigerant and airflow distribution using C-Fit Copper Y-bends.

- Medical Gas Pipelines : Hospitals along with healthcare facilities install C-Fit Copper Y-bends for secure medical gas distribution including oxygen and nitrogen.

- Chemical Processing Plants : C-Fit Copper Y-bends demonstrate excellent resistance against corrosion which makes them ideal for different chemical fluid handling requirements across industrial environments.

- Oil and Gas Industry : Y-bends from C-Fit Copper help maintain efficient fuel and gas transportation through pipeline networks under high-pressure environments.

General Applications:

- Residential Plumbing : Effective water distribution and drainage in conjunction with plumbing systems extends their normal operational lifespan.

- Commercial Buildings : The high-demand applications of plumbing systems and HVAC installations utilize C-Fit Copper Y-bends.

- Renewable Energy Systems : The top-ranked thermal transfer properties of this material lead to its deployment in solar thermal and geothermal systems.