Table of Contents

We are Copper Fitting Manufacturer, where you will find the Best Copper Flanges in Abu Dhabi. Our company deals with manufacturing, dealing, and exporting of these products and ensure that the demands of the clients are met in the best way possible. The products we manufacture include copper flanges that are popular because of their high standards, durability and reliability among other properties admired by different industries. Whether you require off the shelf products or bespoke work, our specialists will ensure that the service received is second to none and the quality is also to the same standard. Sweep through this article and find out why Abu Dhabi’s businesses source their copper flange from us. Therefore we would like to assist you to get the best solution for your assignment.

This Copper Fitting Manufacturer have been supplying many types of copper flanges to the demands of the industries in Abu Dhabi. Our product portfolio is intended to meet various requirements of usage while providing the best properties in each application. Below are the primary types of copper flanges we supply : Below are the primary types of copper flanges we supply:

Slip-On Copper Flanges :

Slip-on flanges do not require welding, they are suitable for low pressures only. They are intended to be slipped over the pipe and then they have to be welded internally and on the external surface in order to be extra reinforced and not leak. These flanges are widely employed where the space available is restricted and in systems of plumbing and piping.

Weld Neck Copper Flanges

Weld neck flanges are desired for their capacity to carry higher pressure and have very high levels of endurance. These flanges are provided with a long tapered hub that is butt-welded to the pipe and this allows free flow and minimizes stress at weld joint. They are commonly applied in the fields where safety comes first, for example, oil and gas fields.

Socket Weld Copper Flanges :

Socket weld flanges are used where the pipes diameter is small but the pressure to which it will be subjected is high. The pipe is placed into the socket end and then fillet welded around the top and this offers a strong and leak-proof union. These flanges are mainly applied in chemical industries and any other industries that require prevention of leakage.

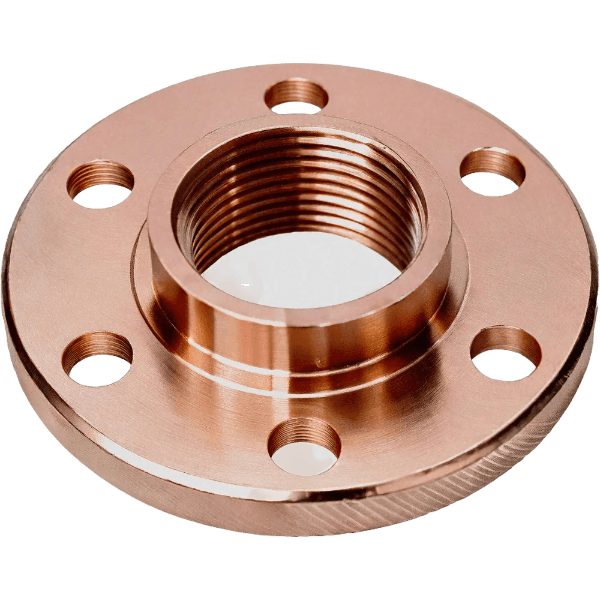

Threaded Copper Flanges

This kind of flanges is especially used when welding of the pipeline is not possible. These flanges have internal threads that mate with the external threads that are provided on the pipe hence allowing easy connection and disconnection. It’s usually applied in low pressure and non-critical applications including in water and the air.

Blind Copper Flanges

Blind flanges are applied for closing the end of an an piping unit or pressure vessel. Unlike other flanges, they do not have a bore and they used in pipe line structures to separate segments or in case you want to access a segment of a pipeline for repairs. Even though they offer high expandability and flexibility they are important in systems that will be expanded in the future.

Lap Joint Copper Flanges

The lap joint flanges are used in combination with a stub end and offers high possibilities of frequent usage of the joint. The aforementioned flanges are used in applications where space is a limiting factor or rapid repair is required. They are usually implemented in flanged joints that are exposed to extreme vibrations and pressure.