Table of Contents

At Copper Fitting Manufacturer it is our honor to establish ourselves as a Copper Flanges Manufacturer, Dealer and Exporter in Bahrain. Customers should expect and receive superior quality products and services and these are assurances that our firm is capable of offering. Our primary product is copper flanges which are manufactured to the highest quality to meet specific needs of use. To add value to our clients we are committed to achieving optimal satisfaction by completing each order in a professional manner. Discover how our technological and quality products and services can benefit your projects as well as organization. Select Copper Fitting Manufacturer for the best quality copper fitting and the best source for copper flanges.

Copper Flanges Manufacturer, Dealer, and Exporter in Bahrain : Types

Copper flange manufacturer is in various types of and in aspiring type of production it depends on the necessary for the piping and industrial system. Understanding the different types can help in selecting the right flange for your application Knowledge concerning the various types will assist in the right selection of the flange that is suitable for your Specific task.

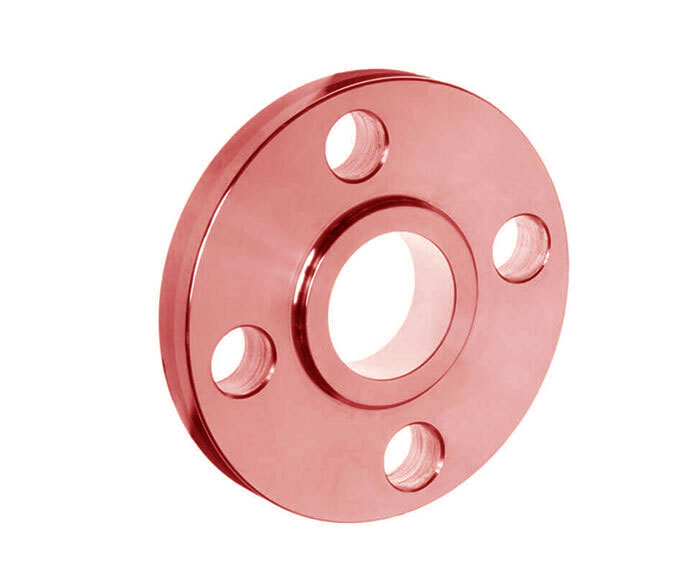

Slip-On Flanges

Slip-on flanges are to be slipped on to the pipe and are welded inside and outside only so that no leakage is seen. They are appropriate on low pressure systems due to there simplicity in construction and they are cheaper to produce. Where the ease of assembly is desired then the slip-on design enables one to align them accurately in the required positions.

Blind Flanges

This flange plays the role of closing a pipeline or a vessel which has been built in the pipeline system. These include routine servicing and checking circumstances under which some portions or section of the system must be isolated. As the last part of engineering system designs, blind flanges eliminate any interchangeability between the fluids or gases in the system making it safe and secure. It comes in various sizes to enable it to provide diameter of the pipe and the pressure needed as well.

Weld Neck Flanges

They are flanges with long tapered neck that is longer than any other type of flanges to enhance strength or support. Also, such a design places them in the category of products that can be used in applications that are subjected to pressure and restraints that do not cause stress concentration. The gradual transition from one diameter to another is useful in attaining a constant flow rate with relatively low levels of turbulence which are quite crucial vi for high pressure systems.

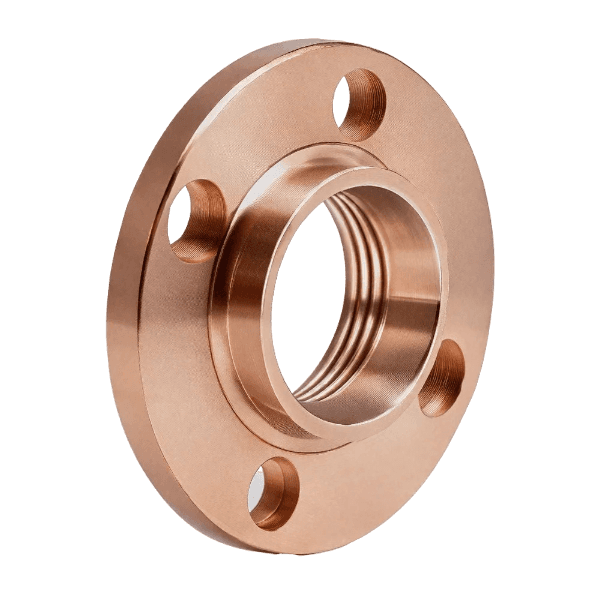

Threaded Flanges

Threaded flanges also have internal threads that can screw onto a pipe thus no need for welding. It is especially suitable in those areas that would not warrant welding in one way or the other. Regularly demanding control of this type of connections, often requiring disassembly and assembly, makes the threaded connection – flanges. The threaded connection enables the sealing elements to be firmly fixed whereas, they can be loosened and tightened again as many times as required.

Socket Weld Flanges

Socket weld flanges are suitable for low pressure large diameter pipes and for small diameter high pressure pipes. Purpose The pipe is passed through the flange and is welded thus offering a strong coupling point. This type of flange is favored due to the fact that it possesses an excellent pressure bearing capability and has high vibration and thermal expansion characteristics. Socket weld flanges are more commonly used for their reliability and strength in industries, which require their products very urgently.

Lap Joint Flanges

Special for utilizing it together with a lap joint stub end, the flanges of lap joint flanges can be conveniently aligned and adjusted. They are excellent for applications where changing or periodically disassembling a system is necessary. The flange of the device is able to be rotated and adjusted so that they can be adjusted according to the specific position that is required, which makes them ideal where alignment is important.

Copper flanges manufacturer are categorized in different types and each utilizes a different function accordingly depending on the needs of the piping system and the process. Therefore, with help of the right flange type selection, you can achieve efficiency, safety, and reliability of the piping ones.

Use of Copper Flanges Manufacturer in Bahrain: Industrial and General Applications

Industrial Applications

- Chemical Processing: In Bahrain, the use of copper flanges is critical since it used in industries where there is corrosion of substances. They find application in reactors, pipelines, and in other equipment where well sealed connections are required in chemicals and related industries.

- Power Generation: In power generation plants, it is used in areas where high temperature as well as high pressure applications occur, copper flanges are used. Their applications are particularly felt in joining parts in boilers turbines and other power generation equipment to facilitate efficiency as well as safety.

- HVAC Systems: There are copper flanges that are used in industrial HVAC systems for joining of the ducts and pipes. They suit the proper control of temperature in the big interesting heating, ventilation and air conditioning systems through proper conductivity of heat and strength.

- Petrochemical Industry: For managing hydrocarbon and other fluids in the petrochemical industry, the copper flanges are used. Some of them can resist severe chemical solutions, and severe conditions, making them applicable for use in the refineries, and chemical plants.

- Pharmaceutical Manufacturing: For example, in the copper flanges manufacturer of drugs, copper flanges are applied in equipment that cannot be contaminated with bacteria or other microorganisms while at the same time having to perform optimally. They offer consistent links in systems used to accommodate and process delicate and precious material.

- Energy Sector: Copper flanges manufacturer provide connection in the structures of wind and solar power systems in Bahrain. Energy production equipment depends on their durability and ability to resist many factors in the environment thus making them favorable.

General Applications

- Residential and Commercial Plumbing: Copper flanges are normally utilized in casing structures of the pipe line used in water supply and drainage systems. They are not prone to corrosion hence long lasting, and suitable for use both in homes and industries, water systems.

- Marine and Offshore: Copper flanges are used to in marine structures such as in shipbuilding and in off-shore structures because of their ability to withstand seawater corrosion. They protect integrity of pipelines and other important components which are exposed to the marine environment.

- Electronics and Electrical Systems: Some of copper flanges application includes, power distribution and grounding systems in the electronics industry. They offer good electrical conductivity thus making electrical connections efficient and reliable to use.

- Heat Exchange Systems: Copper flanges play a very important role in heat exchangers and cooling systems where heat transfer is highly channeled. They improve the efficiency of heat transfer when used in such application areas as heat exchangers.

- HVAC Systems: In addition to its application in industries, copper flanges are used in residential and commercial Heating, Ventilation, and Air conditioning systems. They join a number of parts and assist in sustaining the effectiveness in products relating to heating and cooling.

- Automotive Applications: In car applications these copper flanges manufacturer are applied as heat exchangers and as passages for many fluids. That is why they can be used in those component parts that work under extreme conditions in terms of temperature.