Table of Contents

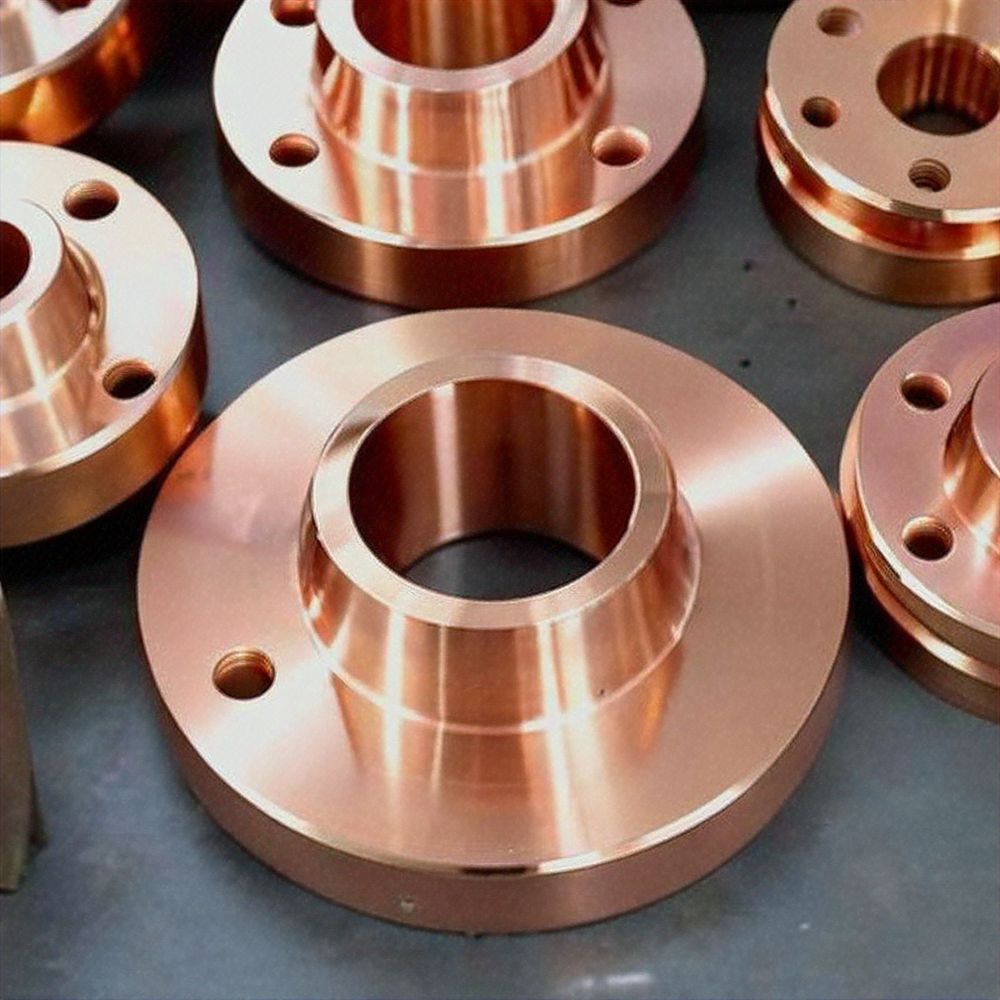

At Copper Fitting Manufacturer, we have always considered ourselves as the Copper Flanges Manufacturer, Dealer, and Exporter in Doha. throughout the years we have grown to become a leader in providing the finest products and service to clients across different industries. Our copper flanges are cut to your exact specifications whether in small quantities for unique installation requirements or in large quantities for a large project. The excellent manufacturing plants that we employ in combination with our strict quality assurance means that every flange that we sell is the best in the market. Quality and reliability are cherished in Doha and that is why while looking for copper flange we consider Copper Fitting Manufacturer as our trusted partner. Be part of our list of satisfied customers and converting to the quality and outstanding services we offer.

Types of Copper Flanges

Copper flanges are central in the piping structures since they act as connecting parts between pipe, valve, pump, and the other equipment. It may be purchased in different types, all of which serve unique functions in operations throughout the world. This paper talks on the various types of copper flanges; a nutshell, it can be seen that one must be in a position to know the right type of copper flanges to be used for a particular project.

Copper Weld Neck Flanges

Weld neck flanges are characterized by a long, tapering hub in which transition into the pipe is smooth and the stress distribution is excellent. They are seen to be used mostly in environments that subject parts to high pressures and high temperatures with much emphasis on the weld joints. The weld neck flange is suitable for applications in harsh environments due to which it is used for applications in such industries as oil and gas, petrochemicals and power generation among others.

Copper Slip-On Flanges

Slip-on flanges are relatively simple to install and thus are suitable for low pressure applications. The pipe rests into the flange and the joint is sealed by fillet welds both internally and at the exterior of the flange. These flanges can be used in almost all the piping systems and need a relatively low cost of manufacturing; thus, they are commonly used in HVAC, plumbing, and industrial applications.

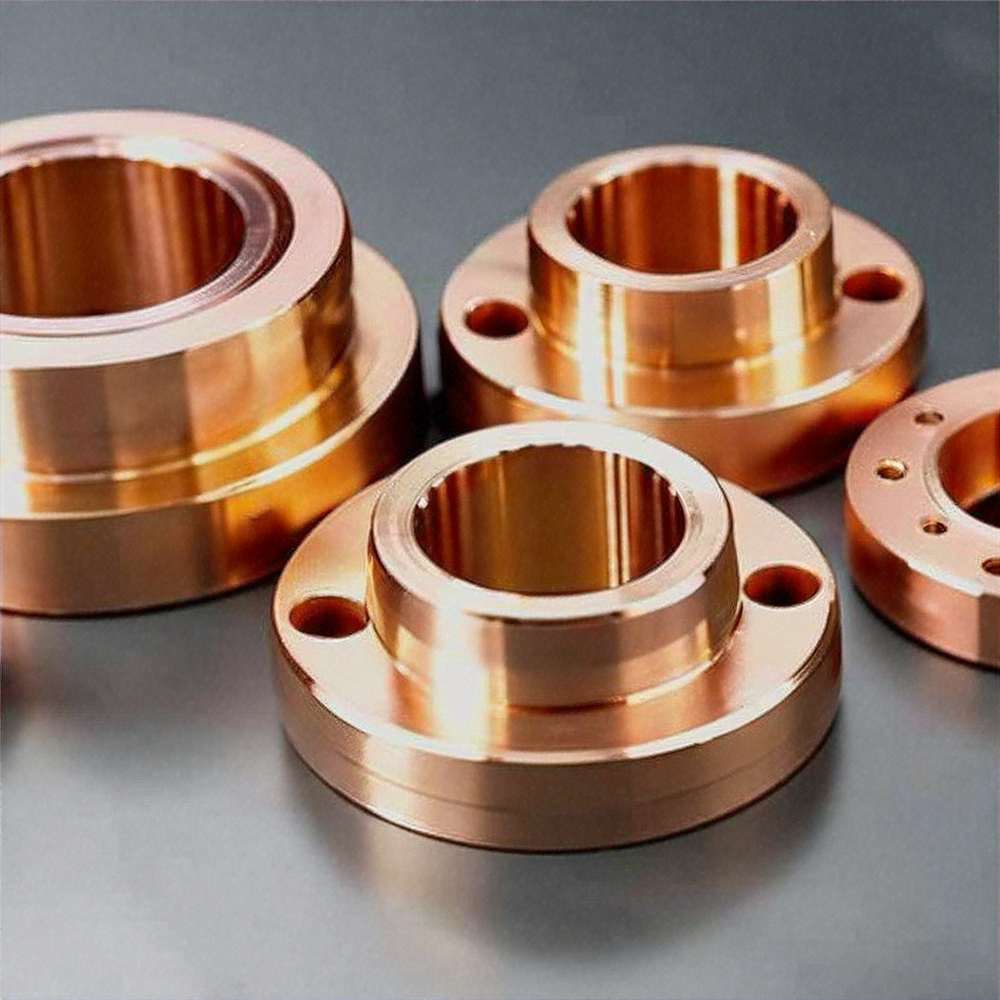

Copper Socket Weld Flanges

Socket weld flanges can be used for small pipes having high-pressure rating on them. The pipe is fitted into the rounded end of the washer like structure known as the flange then welded from the outside. This type of flange is mostly used in chemical processing and other related fields where leak tight connections are necessary. The socket weld flange offer great clamping force with little or no likelihood of leakage.

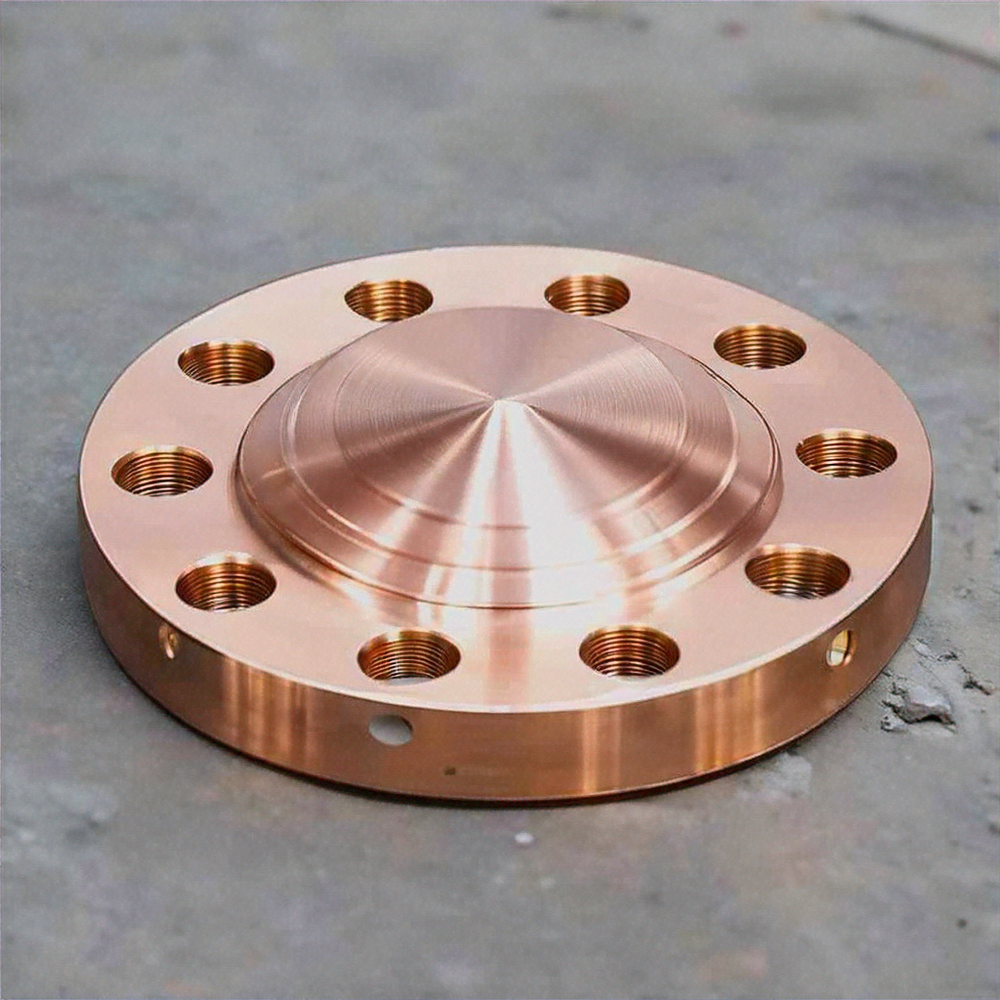

Copper Blind Flanges

Blind flanges are used where it becomes necessary to seal the ends of piping systems or vessels. It does not have a bore which makes it possible for them to shut off the flow of the fluid. Therefore, blind flanges are useful in the systems that likelihood of future expansion or where there will be a need to carry out maintenance. They are also utilized in pressure testing in order to determine the efficacy of the piping system.

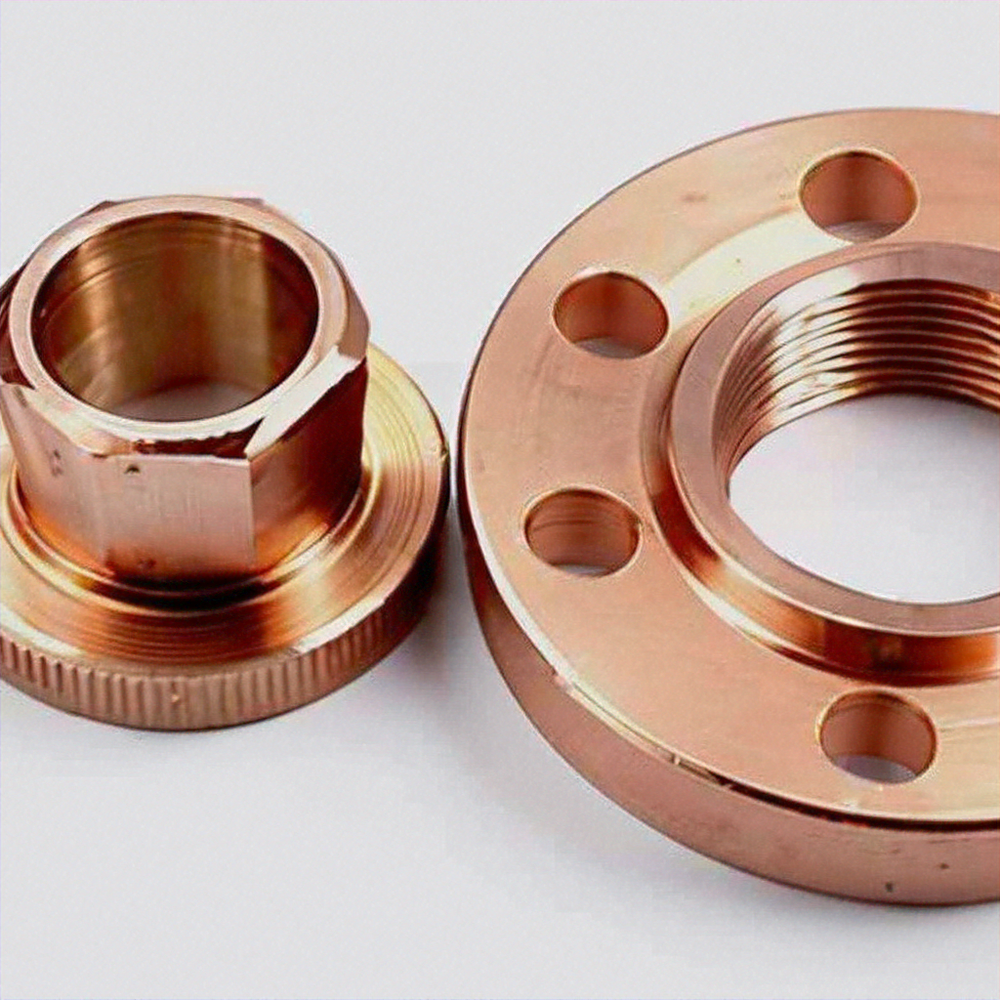

Copper Threaded Flanges

Threaded Flanges Threaded flanges have internal threads thereby making it easier to screw them on the pipe without use of welding. This makes them ideal for systems where welding is not possible or is required to be avoided at all costs or systems where disassembly is necessary for maintenance. Threaded flanges are widely applied for low-pressure non-environmental services such as water and air servings.