Table of Contents

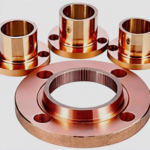

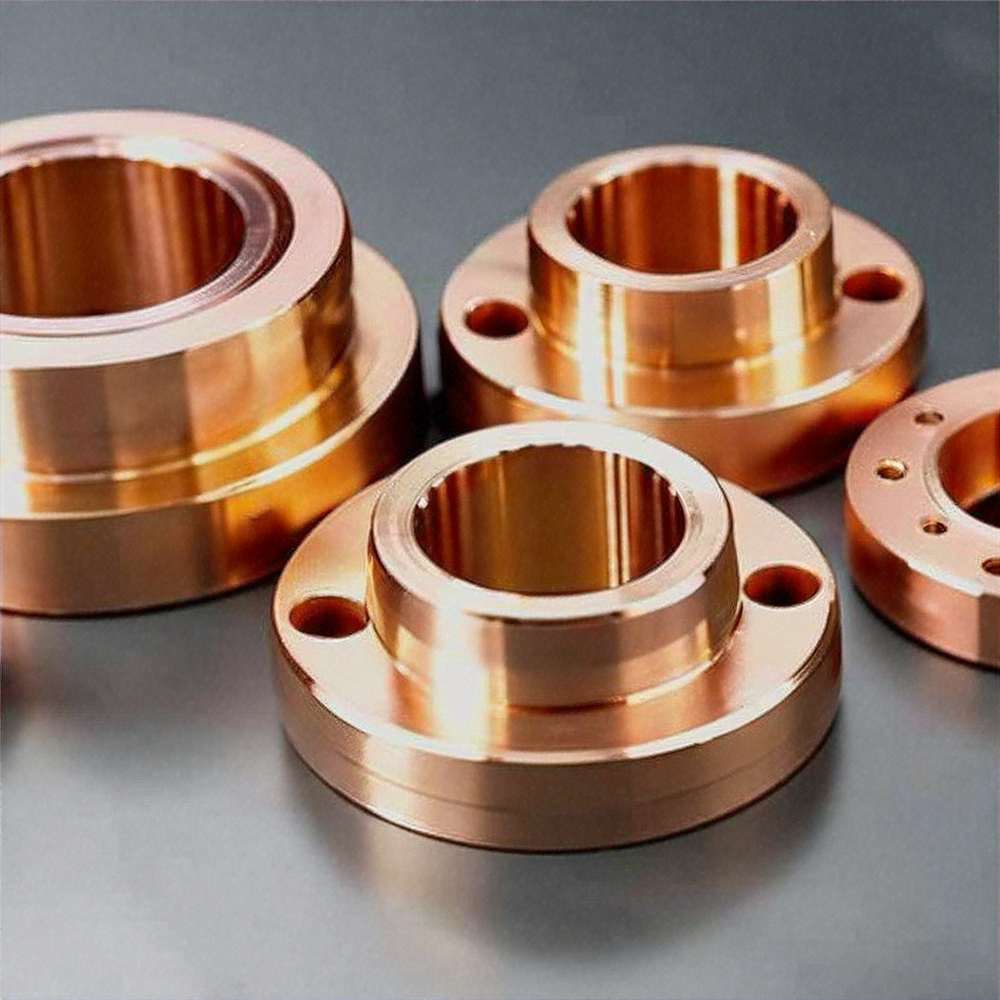

Copper Flanges Manufacturer is well-known in the market as the leading manufacturer, dealer and exporter of copper flanges in Kuwait. Our mission is to provide high quality and the most professional service within the region and this has placed us in a good standing. Whether you are in need of copper flanges that have long service life and high working characteristics for industrial usage or safe distribution services, everything is here. With our team of professional experts, all our products produced undergo international standard to give you our customers the best value for your money. Swing up your projects to new high by choosing the best copper flanges with us.

Copper Flanges Manufacturer, Dealer, and Exporter in Kuwait : Types

Copper flanges manufacturer are marquee products in industries as they are very useful in plumbing, HVAC and other industries where they are used. They are employed for joining pipes valves and other apparatus wherever necessary and also offer a leak proof coupling. Earlier various categories of copper flanges were described and this simply implies that appropriate flange can be opted for depending on the need of a given process. Below is a detailed overview of the most common types of copper flanges : Copper flanges are categorized into many types but the following are the most popular as shown by the following information.

Weld Neck Flanges

Weld neck flanges have a large gradually reducing cylinder that butt joins with the pipe, it offers a high degree of reinforcement to the flange and hardly does fatigue occur in the joint section. These flanges are particularly designed for high pressure system and especially where there is concern of flow of either the liquid or the gas.

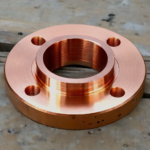

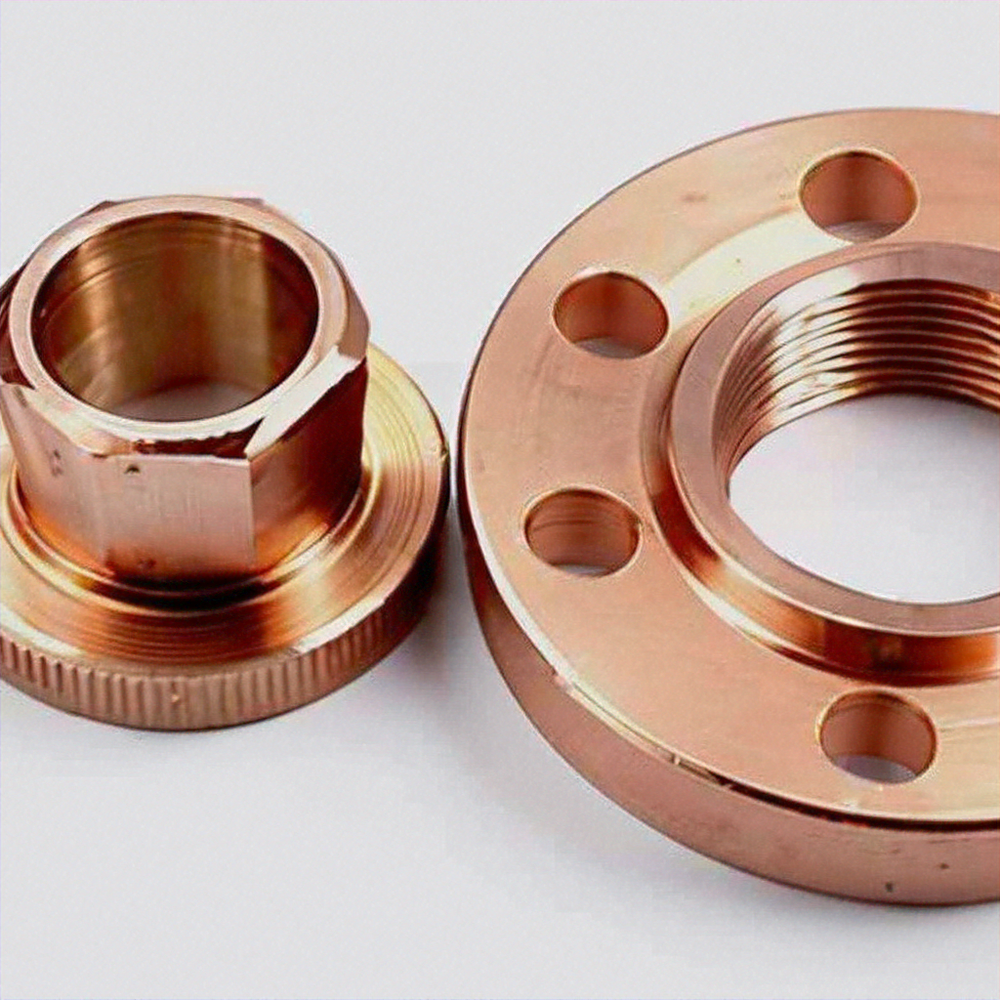

Slip-On Flanges

Slip-on flanges are not at all complex and are used in conditions that involve low pressure. They are affixed on the pipe then it is welded both on the inner and outer surface of the pipe in order to get some form of connecting. However, they are less in strength compared to the weld neck flanges but it is more economical and can be utilized where pressure and temperature is not putting up much.

Socket Weld Flanges

Socket weld flanges are used in pipes with less diameter and mostly in high pressure applications. The pipe is fitted inside a recess within the flange and after that; a welded bead is put round the circumference. This type of a flange has an interior channel that is smooth than the normal flange, thus providing better rates of flow without turbulence.

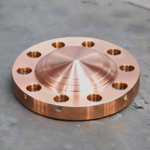

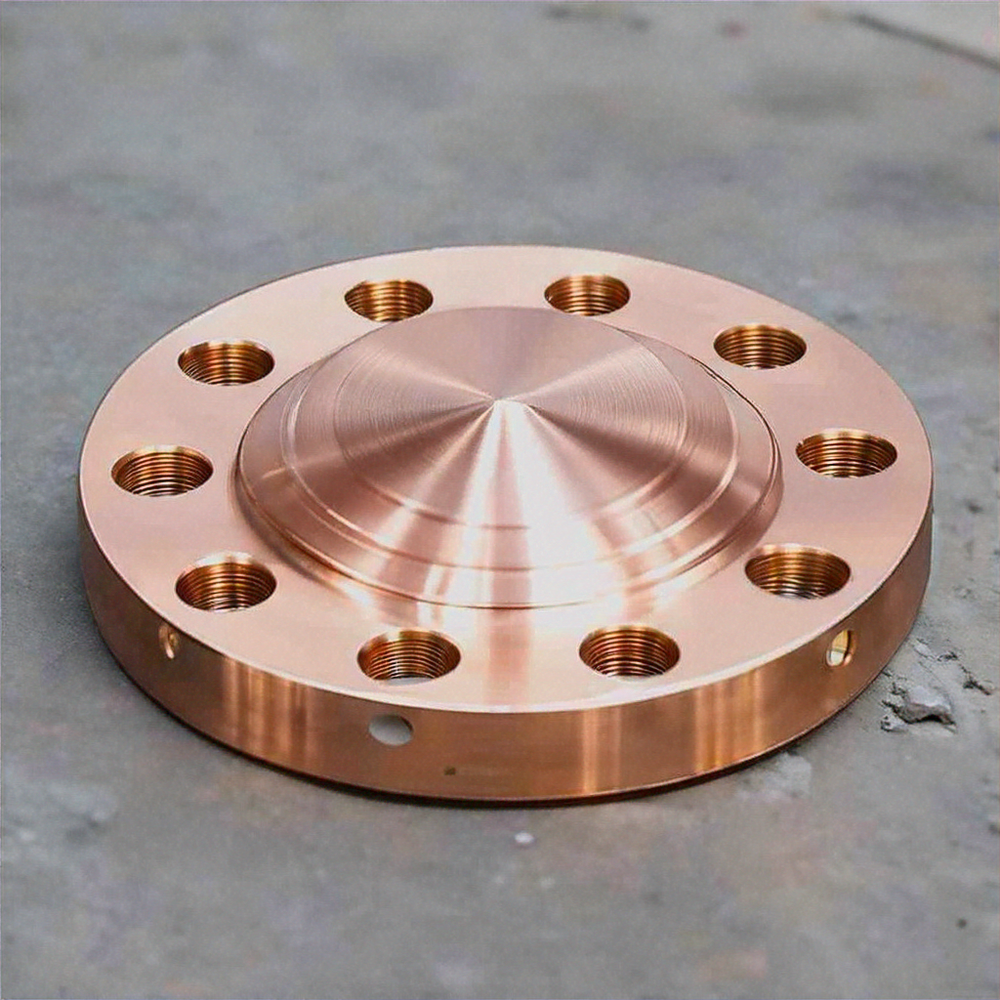

Blind Flanges

Blind flanges are mostly rectangular shaped used to seal the ends of a pipe or valves they are in essence a stopper. They are mostly applied in condition that the system needs to be frequently inspected or maintained because it can be quickly dismantled and installed again. Such blind flanges must be capable of withstanding the pressure within the respective system.

Threaded Flanges

This kind is called screwed flanges or threaded flanges since their inside has matching threads with that of the pipe. They are generally utilized where welding is either not feasible or desirable such as into highly explosive areas. Low pressure and easy to engage and disengage, threaded flanges work have the same advantages as slip-on flanges.

Lap Joint Flanges

Lap joint flanges are designed in association with a stub end where the flange actually does not need to be welded to the pipe. This renders it easy to align and assemble and these are systems where one is likely to disassemble and reassemble many times. Lap joint flanges can be used only in low pressure non-critical services and are generally cheaper than other flanges.

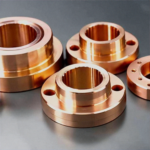

Still each type of copper flange has their individual advantages and therefore due for different applications. For high pressure applications, a strong connection must be made which is possible only if the right type of copper flange is chosen for the connection; on the other hand, while pipe flanges are used for easy removal of pipes formed through connections; copper flanges manufacturer prove beneficial for easy removal of pipes formed through connections. Our company Copper Fitting Manufacturer specializes in serving customers with many types of copper flanges for your variety demands, offering the highest quality and finest performance copper flanges for clients.

Use of Copper Flanges manufacturer in Kuwait: Working in Industries and General Throughout

Copper flanges manufacturer are commonly demanded all over Kuwait in many ways because it is resistant to so many corrosion, high thermal and electrical conductivity. Further, their uses are discussed in industrial and non-industrial sectors in the section below.

Industrial Applications

- Oil and Gas Industry:

Copper flanges are very important for the oil and gas industry where pipes are connected in refineries and in pipelines. Since they can resist high pressure and corrosive environment they are suitable for these applications. - HVAC Systems:

In large HVAC systems, copper flanges are used for joining the pieces together hence guaranteeing leakages and a sound connection. Their thermal conductivity brings efficiency to the systems by minimizing the energy losses here. - Chemical Processing Plants:

Chemical plants use copper flanges since the material does not corrode easily out of abrasive chemicals. They are important in ensure the structural soundness of piping systems used in processing fluids which are reactive or corrosive in nature. - Marine Industry:

Copper flanges are used in the marine industry for such applications as piping systems in ships and in offshore platforms. They are highly resistant to saltwater corrosion hence they can remain useful for a long period of time without frequent repair. - Power Generation:

This is so required in power plants especially the cooling systems and the steam lines and so on are made of copper flanges. Their high thermal conductivity assists in heat transfer processes associated with plant operations thus increasing efficiency.

General Applications

- Residential Plumbing:

In residential facilities, copper flanges are used to join pipes used in the plumbing systems, hence providing a firm and firm less connection. These are used often in water supply pipes because of the material’s ability to resist corrosion. - Fire Sprinkler Systems:

Copper flanges are installed in fire sprinkler system to join the piping system of the sprinklers. Considering that few things are as cringe as an emergency system that didn’t function appropriately, they guarantee the functionality of the system in case of an emergency. - Irrigation Systems:

Thus copper flanges are employed in Iron rite applications to join the pipes in the farm systems. They can withstand prolonged use in outdoors where the devices are bound to experience different types of weather conditions. - Air Conditioning Units:

Copper flanges are also ideal in small AC systems in homes as well as the working places and offices. It play a helpful role in sustaining a strong and effective communications link between the several units of the assembly. - Automotive Applications:

Copper flanges are therefore common in automotive repair particularly in exhaust systems and coolant lines. That is why they are so well suited for these high stress applications because of the capability of resisting heat and corrosion.

Copper flanges manufacturer together with other copper based products are essentials in many industries and other basic uses in Kuwait. Due to their versatility, good physical and chemical characteristics there cannot be anywhere they are not used. For both industrial purposes and residential applications, copper flanges are not only prove to be efficient but also long lasting in function.