Table of Contents

C-Fit Copper Fittings is counted among one of the leading manufacturers, dealers and exporters of copper flanges in India. Thanks to the great emphasis put on our professionalism and accuracy during production, copper flanges supplied by us can be considered to be the best in the market – they are perfect for a number of applications.

Our Copper flanges in India cover the areas of plumbing & HVAC, industrial, and marine applications and offer the highest levels of sealing performance and functionality to the connected pipes. Being an exporter we fulfill the requirement of our international clients and on the same front present a wide range of copper flanges that are made with precision for long lasting performance. We provide the most efficient services and solutions supported by our large network and quality customer care, and therefore are the leading link in the global market. Copper Fittings provides copper flanges in India to meet your every need; see for yourself why Copper Fittings is simply the best.

Copper Flanges manufacturer, dealer, supplier in India

Copper Fittings is one of the top manufacturers and deals in offering copper flanges. Copper Flanges in India are manufactured by our sophisticated plant and qualified personnel in order to meet and or exceed the market demands. We are a recognised industry specialist company that has placed great emphasis on the fact that every copper fitting we manufacture is made with great precision and quality. Our copper flanges in India have a feature of being durable, reliable and accurately machined to the required sizes making it suitable for the following use such as plumbing systems, heating and ventilation and air conditioning systems and industrial uses.

Besides manufacturing, it also undertakes the work of dealer and exporter of the products offered by it so that they can be distributed to the clients without delay. Copper Fittings is a reliable manufacturer of high-quality copper fitting products including copper flanges that are highly sought after in the market because of the excellent services delivered to clients. Select us for the best products and services in the copper fittings niche.

Advantages of Opting for Copper Flanges In India for Your usage

Copper fittings are very durable and possess good thermal conductivity also they are very less corrosive in nature they are ideal for all uses. They offer a long service span and are not frequently replaced; hence, offering the user more value for their money in the long term. Also, copper must be preferred in plumbing and HVAC applications because of its antimicrobial characteristics that ensure safety and hygiene.

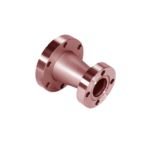

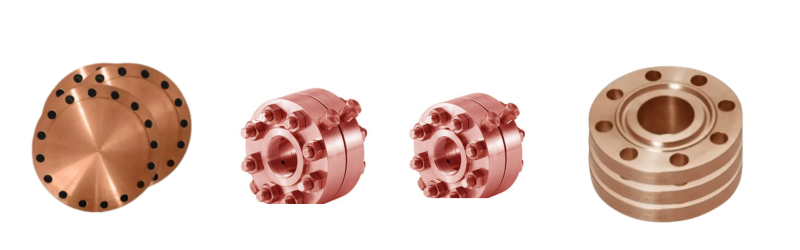

Copper Flanges In India : Types

As for copper flanges, one needs to know that there are various types, and these types are created with regard for some certain applications as well as the connection under consideration. Here are some common types of copper flanges in India: Below are some of the most common types of copper flanges;

- Weld Neck Flanges: Long tapered hub is one of the applications popular in these flanges that work under high pressure. They have to be fixed on the pipe by welding and that make the coupling of both parts very tight to each other.

- Slip-On Flanges: These flanges are slides over pipe and then welded, they known as weld neck flanges and are easier to install. It’s therefore the right area where these components are appropriate for use in low pressure applications.

- Socket Weld Flanges: These flanges are of type where there is a slot in it in which the pipe has to be placed and then have to be brazed. They are used in applications where the required size is small but at the same time the pressure is high.

- Blind Flanges: These flanges are applied to both ends of the piping systems and these flanges do not possess any bore in the middle of these; blind flanges are utilized for pressure or for systems stoppage.

- Threaded Flanges: These flanges are screwed on the pipe and these flanges are used where the pressure is comparatively low and not very severe service.

- Lap Joint Flanges: These do not have welds or fixed to the pipe when used with stub ends, they are most suitable for systems that are required to be dismantled regularly for inspection or for cleaning.

- Reducing Flanges: These flanges are specifically for connecting pipes of different sizes and any system pipe size is suitable to be changed.

- Long Weld Neck Flanges: They are analogous to weld neck flanges but which have the longer tapering neck ranging from the flange hub to the pipe end and this type is useful at conditions that involve high pressure and high temperatures.

Hence the various copper flanges exhibit various features in as much as the application in meeting the needs of the industrial establishments in as much as a sound connection of systems and apparatus is concerned.