Table of Contents

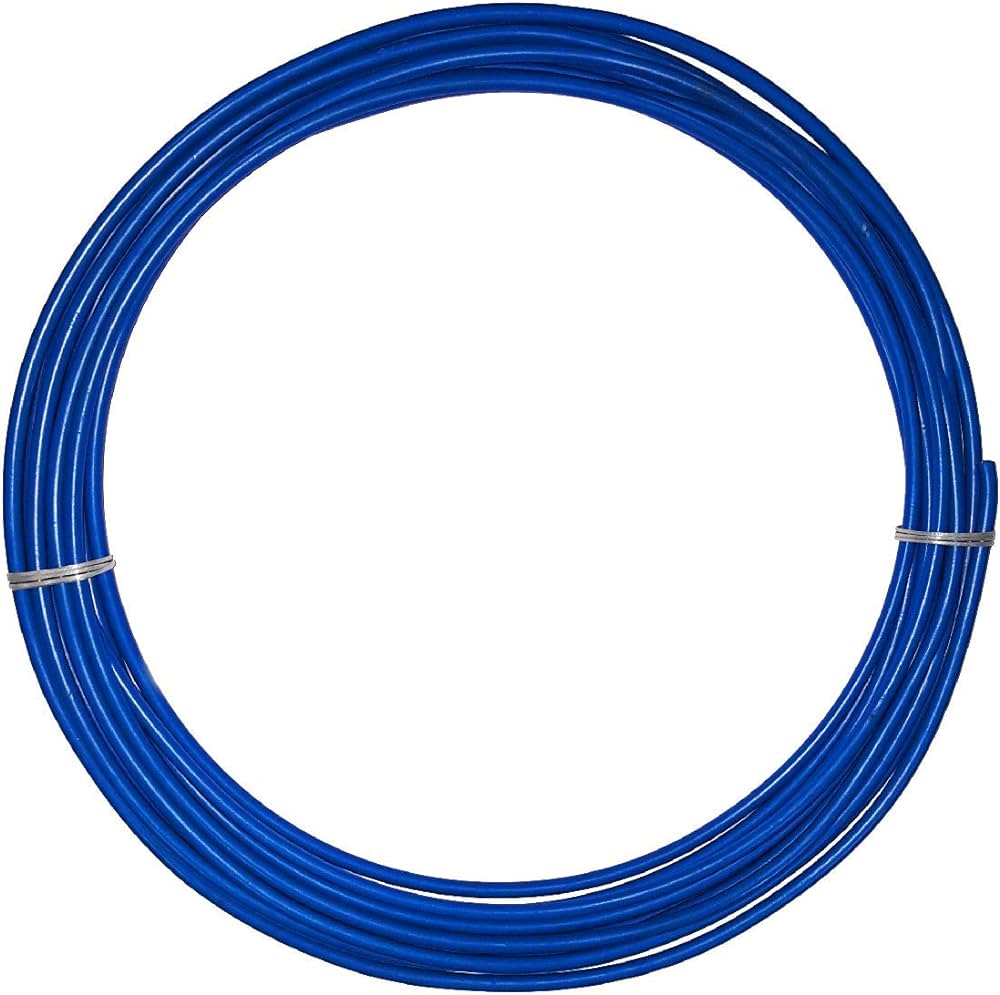

Searching for a reliable Supplier of PVC Coated Copper Pipes & Tubes with quality products in Bahrain? One of the many companies that can be recommended is C-Fit Copper Company, based in India. PVC coated copper pipes and tubes are available in high quality at C-Fit Copper to cater the needs of the companies and its buyers reliable on international quality standard.

These products have features such as high durability, corrosion resistance, and ease of installation, making it possible to be used in construction and Plumbing and HVAC applications in Bahrain. With that rich experience and our strong focus on customer satisfaction, C-Fit Copper of Bahrain is your one-stop-shop for all your PVC coated copper pipe and tube requirements. For more information about the products and services offered by the company, please get in touch with us today.

PVC Coated Copper Pipes Types:

Soft PVC Coated Copper Tubes in Bahrain

Find soft PVC coated copper tubes in Bahrain through C-Fit Copper. These tubes which chemical-proofed copper tubes have, are more durable having PVC protection. For use in various conditions, they guarantee efficiency in plumbing and HVAC industries throughout Bahrain.

Hard PVC Coated Copper Pipes in Bahrain

At C-Fit Copper, we have hard PVC coated copper pipes for sale in Bahrain. These pipes blend the structural capabilities of copper pipe with the corrosion resistant characteristics of PVC, making them suited for use in several fields. As durable and reliable, they provide lasting solutions in plumbing, HVAC, and in other areas.

MGL PVC Coated Copper Tube in Bahrain

MGL PVC Coated Copper Tube in Bahrain is versatile and offers excellent protection from corrosion to pipeline systems. These tubes are offered by C-Fit Copper can be used for various applications in plumbing and HVAC systems in Bahrain because of the copper content and the PVC cover that protects the tubes from harm.

PVC Coated Copper Pipes Specification, Sizes, Grades:

| Standards | EN13348/ BS EN 1057 |

| Size | 6mm to 108 mm |

| Length | 3 meter |

| Tensile Strength | 220 Mpa |

| P.V.C Thickness | 0.014”to 0.059” |

| Material | Copper |

| Application | Gas Handling |

PVC Coated Copper Pipes Chemical Composition:

| Copper Pipe (Incl. Silver) | 99.85% Min. |

| Phosphorus | 0.013 to 0.5% |

| Total Impurities | 0.06% Max. |

Mechanical Property Of PVC Coated Copper Pipes:

| Density | 8.89 g/cm3 |

| Melting Point | 1370 °C (2500 °F) |

| Tensile Strength | Psi – 1,15,000 , MPa – 790 |

| Yield Strength (0.2%Offset) | Psi – 52,000 , MPa – 355 |

| Elongation | 40 % |

PVC Coated Copper Pipes Physical Property:

Standard | Copper No. | Chemical Composition | Mechanical Properties | ||||

|---|---|---|---|---|---|---|---|

| CU% | P% | Temper | Tensile strength (Mpa) | Elongation(%) | Average Grain Size (mm) | ||

| ASTM B280/68 | C12200 | 99.9 | 0.015 to 0.040 | >60 | >205 | >40 | >0.040 |

| >50 | >245 | ||||||

PVC Coated Copper Pipes Weight Chart:

It greatly assist you in identifying the right pipe to use in your project since C-Fit Copper’ PVC Coated Copper Pipes weight chart helps to look up the pipe weight of the size you want to use. Without fail we have pipes that offer better durability as well as high efficiency in various applications.

| Type | Size d2 t2/ d1 t1 | O.D. of the tube d1/d2/d3 | Thickness of Insulator t1/t2/t3/t4 | Length | Material | Weight Pounds/feet |

|---|---|---|---|---|---|---|

| P2320 | 1/4-0.032 3/8-0.032 | 1.02-0.87-1.89 | 0.35-0.2 | 30ft ~100ft | 0 | 0.233 |

| P2330 | 1/4–0.032 1/2–0.032 | 1.30-0.87-2.17 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.286 |

| P2420 | 1/4-0.032 3/8-0.039 | 1.42-0.87-2.29 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.39 |

| P2520 | 1/4–0.032 5/8–0.032 | 1.42-1.02-2.44 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.44 |

| P3620 | 3/8–0.0329 3/4–0.039 | 1.54-1.02-2.56 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.569 |

| P4620 | 1/2–0.032 3/4-0.039 | 1.54 1.30 2.84 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.629 |

Advantages and Disadvantages of PVC Coated Copper Pipes

Advantages:

- Corrosion resistance: The PVC coating covers and can prevent the pipes from corrosion and increasing the lifespan of the pipes.

- Durability: The coating gives and extra layer of protection and makes the pipes stronger.

- Insulation: PVC coating offers thermal insulation and hence, energy loss through HVAC systems is reduced.

- Reduced condensation: The coating cuts down the condensation on the pipe surface making the water damage less likely.

- Aesthetic appeal: PVC coated pipes provide a cleaner, more polished look, which makes them suitable for exposed installations.

Disadvantages:

- Higher cost: The cost of PVC coated pipes is typically higher than that of uncoated pipes.

- Complex installation: The coating complicates installation as it may need the use of some specialized tools or techniques.

- Limited temperature range: PVC coating can limit the temperature range in which the pipes can be used.

- Potential for damage: If the coating becomes damaged, the pipe will be exposed to corrosion.

- Environmental concerns: PVC is a polymer that gives rise to the issue of environmental impact and sustainability.