Table of Contents

At Copper Fitting Manufacturer, we focus our efforts on manufacturing PVC Coated Copper Pipes to fit the specific needs of customers in Nepal. These pipes are highly resistant to corrosion, flexible and are characterized by high tensile strength, thus suitable for use in any number of industries as well as general use. When it comes to the commercial applications such as HVAC or refrigeration or even plumbing, our products are nothing short of the best. This commitment has placed us as a reliable firm in the region with a ready and able clientele in our products that meets international standards.

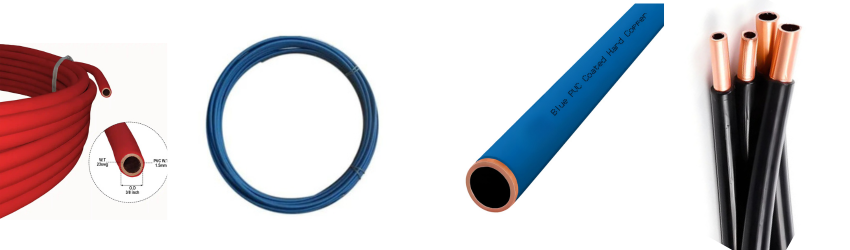

PVC Coated Copper Pipes & Tubes Manufacturer and Exporter in Nepal :- Types

These PVC Coated Copper Pipes can be classified by different types to suit different needs and requirements. These types provide solutions for required degree of durability flexibility and necessary impact and environmental resistance. Let’s take a glimpse into the two overall types that serve as the core of our products line or offer.

Soft PVC Coated Copper Pipe

Flexible soft PVC coated pipes are makings from light weight and high flexibility making them suitable for applications that require bending. They are applied frequently in refrigeration systems and HVAC installations because of the ability to install them in restricted areas. Also, the softness of the coating makes them durable because they display resistance to moisture and chemicals.

Hard PVC Coated Copper Pipe

Heavy Duty PVC-Coated pipes are made for industries requiring high tensile strength and pipe stiffness. These pipes afford better physical protection and therefore have wide applications including in industries like the oil and gas, and industrial cooling. One cannot fail to mention that these structures give the circuits their stability and guarantee efficient performance in harsh working conditions.

PVC Coated Copper Pipes in Nepal :- Properties

These PVC Coated Copper Pipes have garnered a reputation for offering the best characteristics for ultimate performance in the diverse Nepalese climate as well as industrial sector. Such characteristics enable the product to be used in competitive applications that offer end-users durability and reliability.

- Durability : The blend of copper and PVC coating makes their lifespan long because they are protected from wear and tear as well as Ultraviolet (UV) radiation and high or low temperatures.

- Flexibility : Soft PVC coatings are the most flexible, making them very ideal for complicated layouts and narrow spaces, although not affecting their performance.

- Corrosion Resistance : The PVC coating also serves the purpose of outer skin and shield the copper pipes from moisture, chemical and other unfriendly conditions.

- Thermal Conductivity : Another advantage of Copper is its good conductivity of heat and with PVC coated, there is no wasting of energy to heat or cool fluids and gases and therefore, the efficiency of these pipe is amazing in heated or cooled applications.

- Leak Resistance : This compatibility makes the copper and PVC combination virtually immune to leakage, common in other systems like health-related gases and facility temperature control.

- Eco-Friendly : Coated Copper Conductor, or simply Copper covering with PVC, is recyclable hence making the Contline plus product green by having a long life and little or no wastage.

PVC Coated Copper Pipes Specification, Sizes, Grades :

The PVC Coated Copper Pipes that we offer are produced in various size, weight and dimensional requirements to meet different needs. This keeps the customer preferably positioned throughout Nepal for the acquisition of the most appropriate product depending on the demand be it for plumbing, heating and cooling systems or other special purposes. The option of having the products customized also brings out the fact that our products can suit any project.

| Standards | EN13348/ BS EN 1057 |

| Size | 6mm to 108 mm |

| Length | 3 meter |

| Tensile Strength | 220 Mpa |

| P.V.C Thickness | 0.014”to 0.059” |

| Material | Copper |

| Application | Gas Handling |

PVC Coated Copper Pipes Weight Chart :

| Type | Size d2 t2/ d1 t1 | O.D. of the tube d1/d2/d3 | Thickness of Insulator t1/t2/t3/t4 | Length | Material | Weight Pounds/feet |

|---|---|---|---|---|---|---|

| P2320 | 1/4-0.032 3/8-0.032 | 1.02-0.87-1.89 | 0.35-0.2 | 30ft ~100ft | 0 | 0.233 |

| P2330 | 1/4–0.032 1/2–0.032 | 1.30-0.87-2.17 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.286 |

| P2420 | 1/4-0.032 3/8-0.039 | 1.42-0.87-2.29 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.39 |

| P2520 | 1/4–0.032 5/8–0.032 | 1.42-1.02-2.44 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.44 |

| P3620 | 3/8–0.0329 3/4–0.039 | 1.54-1.02-2.56 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.569 |

| P4620 | 1/2–0.032 3/4-0.039 | 1.54 1.30 2.84 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.629 |

PVC Coated Copper Pipes Chemical Composition :

| Copper Pipe (Incl. Silver) | 99.85% Min. |

| Phosphorus | 0.013 to 0.5% |

| Total Impurities | 0.06% Max. |

Mechanical Property Of PVC Coated Copper Pipes :

| Density | 8.89 g/cm3 |

| Melting Point | 1370 °C (2500 °F) |

| Tensile Strength | Psi – 1,15,000 , MPa – 790 |

| Yield Strength (0.2%Offset) | Psi – 52,000 , MPa – 355 |

| Elongation | 40 % |

PVC Coated Copper Pipes Physical Property:

Standard | Copper No. | Chemical Composition | Mechanical Properties | ||||

|---|---|---|---|---|---|---|---|

| CU% | P% | Temper | Tensile strength (Mpa) | Elongation(%) | Average Grain Size (mm) | ||

| ASTM B280/68 | C12200 | 99.9 | 0.015 to 0.040 | >60 | >205 | >40 | >0.040 |

| >50 | >245 | ||||||

PVC Coated Copper Pipes in Nepal :- Applications

The PVC Coated Copper Pipes are widely utilized in various industrial and general applications throughout Nepal. These pipes are a matter of necessity in today’s manufacturing units, making sure that the refrigeration is all right, or in the plumbing of residential complexes. They are durable and free from breakdown when subjected to different stresses making them suitable for use.

Industrial Applications

- HVAC Systems : Maintains proper cooling and heating system of wide industrial buildings with high performance and sturdiness.

- Refrigeration : Delivers dependable performance for refrigeration units used in food preserving and storage industries.

- Oil and Gas : Applied in pipelines for conveying gases with safety and adequate resistance against corrosion.

- Industrial Cooling : Provides super heat dissipation rate that is used in cooling process of manufacturing industries.

- Chemical Processing : Does not corrode easily and thus is widely used to transport chemically active fluids.

General Applications

- Residential Plumbing : Ensures a long-lasting and leak-free performance on residential water system applications .

- Fire Safety Systems : Provides some form of reliability in fire sprinkler systems because it can undergo high pressure as well as high temperature.

- Solar Energy Systems : Improves efficacy of the solar water heaters since the material has a great thermal conduction factor.

- Gas Supply : Applied in the distribution of natural and town gas for home and business use due to the material’s long-lasting property and safety features.

- Air Conditioning : Offers enhanced cooling comfort to homeowners and occupants of the residential and commercial buildings through air conditioning systems.

PVC Coated Copper Pipes :- Advantages

- High Performance : Copper extruded aluminum is preferred because its inherent qualities when blended together with PVC coated aluminum perform highly when exposed to exogenous pressures.

- Long Lifespan : The outside layer of PVC Provides additional protection and increase the lifecycle of the pipes as used in the industrial and household applications.

- Cost-Effective : The minimum of costs necessary for the maintenance of these pipes in addition to the long service span make them ideal.

- Versatility : Being versatile, the system can be used in HVAC/R, plumbing, fire protection, and more.

- Safety : Free from toxicity and capable of withstanding leaks making it suitable for use in essential operations like health related gas pipelines.

- Eco-Friendly : Made of fully recyclable materials to support sustainable consumption and impacts a minimum on the environment.