Table of Contents

We are a well-established firm engaged in Offering PVC Coated Copper Pipes & Tubes to our clientele in the United States of America Our rendered product range is highly appreciated for its sturdiness and suitability for a vast array of uses in various industries and other sectors roughly the globe. Our pipes and tubes are widely popular for its high sustainable strength, corrosion protection features, and can offer long service life solution in different surroundings. By always embracing precision engineering and international standers, we tend to the HVAC systems, refrigeration and plumbing in the United States of America offering reliable services for any project.

PVC Coated Copper Pipes & Tubes Manufacturer and Exporter in USA :- Types

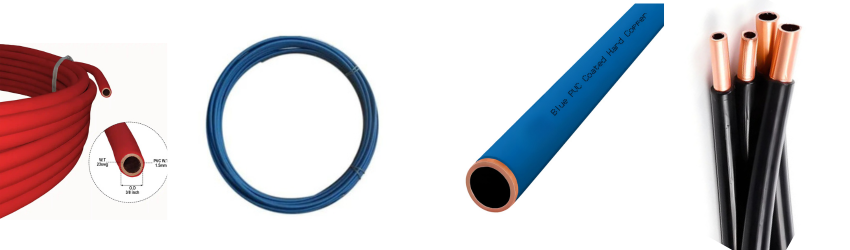

The types of our PVC Coated Copper Pipes & Tubes include the following to suit certain functions of industries. For narrow platforms, our selection offers mobility; for applications requiring sturdier platforms, we have options for that too. The two are Soft PVC Coated and Hard PVC Coated Copper Pipes where each type is created to fit a specific model and niche.

Soft PVC Coated Copper Pipe

These pipes have a very flexible design and are very ideal for any installations that might be involving very sharp bends or sections of limited space. These are covered by a soft textured layer of PVC that guarantees them high levels of resistance to moisture and corrosion. Mainly used in the refrigerator and Air conditioning system they make the functioning and installation smooth.

Hard PVC Coated Copper Pipe

This is arguably the strongest PVC coated copper pipes designed for use in industrial applications that require high tolerance of strength and stiffness. The outer layer of these reinforcements is made from highly durable PVC which improves its tolerance to external mechanical forces and conditions. Such pipes are employed in service of oil and gas transporting pipelines, industrial freezing applications and high pressure plumbing solutions.

PVC Coated Copper Pipes in USA :- Properties

The PVC Coated Copper Pipes are known for such properties which make it most suitable to be used in the USA in various uses. These characteristics make them offer the best performing materials with an optimum condition of strength, flexibility, and resistance. These properties meet both industrial and general sector requirements of durability and dependability.

- Durability : These are additional features which the PVC coating provides on the pipe by minimizing the effects of wear and tear. This makes them ideal for an environment where exposing to physical stress or rough handling is always a norm.

- Corrosion Resistance : The final layer of PVC protects the copper material from the effects of moisture, chemicals and salts, making the core suitable to function in difficult conditions for many years.

- Flexibility : Flexible PVC coatings enable the pipes to flex thereby appropriate for installations that need complex routing or confined access without the need for rigidity.

- Impact Resistance : Extraordinary mechanical properties of hard PVC coatings will give extra layer of defense to the pipes against outside pressures, fractious forces and any kind of aberrant punctures during its transportation or functioning.

- Thermal Conductivity : Even with the outer PVC layer, these pipes remain highly thermally conductive like copper, and are appropriate for uses in refrigeration and heating, ventilation, and air conditioning.

- Environmentally Friendly : Copper and PVC are both recyclable products therefore these pipes are environment friendly and suitable to the American green movement.

PVC Coated Copper Pipes Specification, Sizes, Grades :

They are durable and long-lasting in functional applications such as plumbing and industrial uses because of features within OUR PVC Coated Copper Pipes such as sizes, weight and dimensions. From daven compact diameters for residential plumbing to grate products for larger systems application, all the options guarantee easy incorporation into certain systems. This variety enables the clients to select their operational items that are efficient and easy to fix since they meet their expectations.

| Standards | EN13348/ BS EN 1057 |

| Size | 6mm to 108 mm |

| Length | 3 meter |

| Tensile Strength | 220 Mpa |

| P.V.C Thickness | 0.014”to 0.059” |

| Material | Copper |

| Application | Gas Handling |

PVC Coated Copper Pipes Weight Chart :

| Type | Size d2 t2/ d1 t1 | O.D. of the tube d1/d2/d3 | Thickness of Insulator t1/t2/t3/t4 | Length | Material | Weight Pounds/feet |

|---|---|---|---|---|---|---|

| P2320 | 1/4-0.032 3/8-0.032 | 1.02-0.87-1.89 | 0.35-0.2 | 30ft ~100ft | 0 | 0.233 |

| P2330 | 1/4–0.032 1/2–0.032 | 1.30-0.87-2.17 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.286 |

| P2420 | 1/4-0.032 3/8-0.039 | 1.42-0.87-2.29 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.39 |

| P2520 | 1/4–0.032 5/8–0.032 | 1.42-1.02-2.44 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.44 |

| P3620 | 3/8–0.0329 3/4–0.039 | 1.54-1.02-2.56 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.569 |

| P4620 | 1/2–0.032 3/4-0.039 | 1.54 1.30 2.84 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.629 |

PVC Coated Copper Pipes Chemical Composition:

| Copper Pipe (Incl. Silver) | 99.85% Min. |

| Phosphorus | 0.013 to 0.5% |

| Total Impurities | 0.06% Max. |

Mechanical Property Of PVC Coated Copper Pipes:

| Density | 8.89 g/cm3 |

| Melting Point | 1370 °C (2500 °F) |

| Tensile Strength | Psi – 1,15,000 , MPa – 790 |

| Yield Strength (0.2%Offset) | Psi – 52,000 , MPa – 355 |

| Elongation | 40 % |

PVC Coated Copper Pipes Physical Property:

Standard | Copper No. | Chemical Composition | Mechanical Properties | ||||

|---|---|---|---|---|---|---|---|

| CU% | P% | Temper | Tensile strength (Mpa) | Elongation(%) | Average Grain Size (mm) | ||

| ASTM B280/68 | C12200 | 99.9 | 0.015 to 0.040 | >60 | >205 | >40 | >0.040 |

| >50 | >245 | ||||||

PVC Coated Copper Pipes in USA :- Applications

PVC Coated Copper Pipes industry is used in industrial and general sectors in USA. Due to their high performance, interchangeability and insensitivity to environmental conditions, they are essential to applications where they operate. All these pipes serve crucial purposes of boost the efficiency, safety and durability in several applications.

Industrial Applications

- HVAC Systems : Employed widely for heat exchange and cooling purposes, to maintain the imperative productivity of air conditioning systems in commercial as well residential buildings.

- Oil and Gas Industry : Well suited for use in locations which undergo rapid corrosion or where rigorous use is required due to their immovability.

- Refrigeration Systems : It plays a very important role of maintaining safe and efficient refrigeration in the applications of commerce and industries by avoiding leakage and resultant contamination.

- Chemical Plants : Copper wire being used is very reliable in dealing with corrosive chemicals due to the outermost layers of PVC.

- Power Plants : Preferred in heat exchange and cooling systems that need great coefficient of thermal conduction and heat tolerance.

General Applications

- Residential Plumbing : Rich for application in operations that require safe and efficient water supply systems for a long time with the absence of corrosion.

- Fire Safety Systems : enhances the reliability of the fire suppression systems because they possess high strength and are resistant to any condition.

- Solar Energy Systems : Perfect for interconnecting solar panels and for the transfer of power due to the low thermal resistance.

- Irrigation Systems : Wide industrial grade flexible products are useful in the irrigation systems with the pipes being rigid yet highly resistant.

- Medical Gas Systems : Ensures safe passage of gas in health facilities to meet efficiency in delivery, purity as well as past reliability stopping at nothing.

PVC Coated Copper Pipes :- Advantages

- Longevity : The ability to give a product a longer lifespan also decreases the money that has to be spent on product maintenance and replacement.

- Corrosion Protection : Moisture, chemicals, as well as other corrosive factors are well shielded by PVC coating.

Versatility : Applicable in commercial and domestic uses, which means that it offers general solutions for each of the areas. - Thermal Efficiency : Recalls high thermal factor conducting copper which is perfect for the heating and cooling systems.

- Cost-Effective : Balances toughness and effectiveness, thereby offering customer dollar value throughout a product’s lifecycle.

- Eco-Friendly : Recyclable materials are sustainable because they allow for limited harm in an environment.