Table of Contents

C-Fit Copper Manufacturer offers the highest quality of PVC Coated Copper Pipes and Tubes in UK. Some of them are well known for their durability and reliability of its use in various industries and so many applications. They are protected by a durable PVC that makes them fit for use in any situation indoors or out. As a result of our commitment to quality and constant development, we serve the HVAC, plumbing and industrial sectors throughout the United Kingdom making us a reputable brand.

PVC Coated Copper Pipes & Tubes Manufacturer and Exporter in UK :- Types

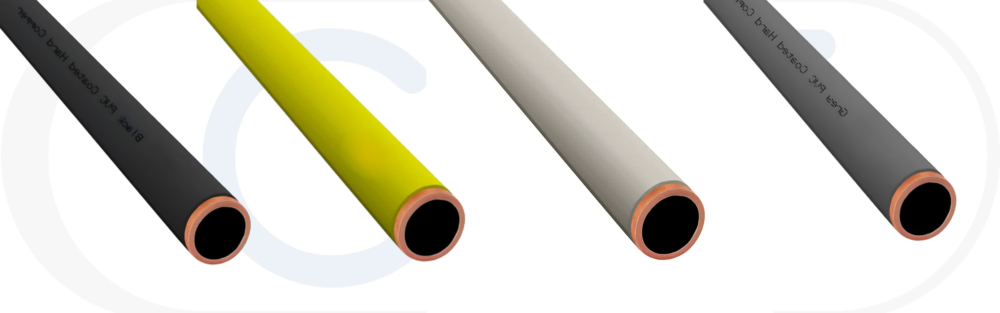

The various types of our PVC Coated Copper Pipes are developed according to different applications for the best performance. These pipes are available in two primary variants, each tailored to specific uses: Soft PVC Coated Copper Pipes that are suitable during installation exercises and the Hard PVC Coated Copper Pipes for hard usage.

Soft PVC Coated Copper Pipes in UK

Soft PVC Coated Copper Pipes are used for installations where flexibility is needed and therefore they can be easily installed. The outer layer of soft PVC gives good anti-corrosive properties to resist the pipe substance while making the pipes flexible to bend or turn. They are most commonly used in systems in residential property, heating/cooling systems as well as installations which require flexibility in piping. As lightweight pieces of equipment they are also easy to transport and handle.

Hard PVC Coated Copper Pipe in UK

Hard PVC Coated Copper Pipes designed for high tensile strength applications and are ideal for industrial and commercial use. Following are the detailed key features of this PVC. The external layer of this PVC is hard which enhances mechanical and chemical resistance which includes UV and chemical resistance. These pipes are used for oil and gas transmission, low and high temperature applications such as refrigeration applications and heavy duty HVAC applications that would give long lasting pipe life and require little or no maintenance.

PVC Coated Copper Pipes in UK :- Properties

PVC Coated Copper Pipes are pipes that combine natural properties of copper alloy with the protective capabilities of PVC coating. This integration guarantees high performance and therefore are suitable for the tough weather and industrial conditions in the UK (United Kingdom). When it comes to corrosion, thermal, acoustic or any other form of efficiency, these pipes are designed for use in various applications and respects to their reliability.

- Durability : Copper and PVC as materials guarantee long service life, as they cannot easily wear out under conditions of high mechanical and thermal load. These characteristics make the pipes resilient especially for use in the industrial and residential facilities.

- Corrosion Resistance : PVC coating also helps to protect the pipe from corrosion as a result of moisture, chemical and even the climate. This also reduces the life span of the pipes even in the coastal areas’ or the humid regions.

- Flexibility : Soft PVC coated types are easy to bend by creating a contour for installation and thus saves a lot of man hours and resources. This feature is most effective for tight or complex environments.

- Thermal Conductivity : From thermal conductivity, copper plays its role in heat transfer maximization, while the PVC layer slows heat transfer to minimize performance losses in HVAC and refrigeration systems.

- UV Resistance : The pipes are coated with hard PVC that obscures the pipes from UV rays thereby preventing the pipes from degrading when used outdoors.

- Impact Resistance : The outer layer made of rigid PVC also cushions the product against mechanical stress during it’s transportation and installation.

PVC Coated Copper Pipes in UK : Specification, Sizes, Grades

PVC Coated Copper Pipes come in a variety of pipe sizes, weigh and dimensions which permit different application connections. This variation makes it possible for it to fit in various systems, right from the residential level to the industrial category of plumbing systems. They have been found to be available in custom lengths and diameters which make it easy to order and install standards basing on your requirements thereby cutting on costs in wastage.

| Standards | EN13348/ BS EN 1057 |

| Size | 6mm to 108 mm |

| Length | 3 meter |

| Tensile Strength | 220 Mpa |

| P.V.C Thickness | 0.014”to 0.059” |

| Material | Copper |

| Application | Gas Handling |

PVC Coated Copper Pipes in UK Weight Chart :

| Type | Size d2 t2/ d1 t1 | O.D. of the tube d1/d2/d3 | Thickness of Insulator t1/t2/t3/t4 | Length | Material | Weight Pounds/feet |

|---|---|---|---|---|---|---|

| P2320 | 1/4-0.032 3/8-0.032 | 1.02-0.87-1.89 | 0.35-0.2 | 30ft ~100ft | 0 | 0.233 |

| P2330 | 1/4–0.032 1/2–0.032 | 1.30-0.87-2.17 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.286 |

| P2420 | 1/4-0.032 3/8-0.039 | 1.42-0.87-2.29 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.39 |

| P2520 | 1/4–0.032 5/8–0.032 | 1.42-1.02-2.44 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.44 |

| P3620 | 3/8–0.0329 3/4–0.039 | 1.54-1.02-2.56 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.569 |

| P4620 | 1/2–0.032 3/4-0.039 | 1.54 1.30 2.84 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.629 |

PVC Coated Copper Pipes Chemical Composition:

| Copper Pipe (Incl. Silver) | 99.85% Min. |

| Phosphorus | 0.013 to 0.5% |

| Total Impurities | 0.06% Max. |

Mechanical Property Of PVC Coated Copper Pipes:

| Density | 8.89 g/cm3 |

| Melting Point | 1370 °C (2500 °F) |

| Tensile Strength | Psi – 1,15,000 , MPa – 790 |

| Yield Strength (0.2%Offset) | Psi – 52,000 , MPa – 355 |

| Elongation | 40 % |

PVC Coated Copper Pipes Physical Property:

Standard | Copper No. | Chemical Composition | Mechanical Properties | ||||

|---|---|---|---|---|---|---|---|

| CU% | P% | Temper | Tensile strength (Mpa) | Elongation(%) | Average Grain Size (mm) | ||

| ASTM B280/68 | C12200 | 99.9 | 0.015 to 0.040 | >60 | >205 | >40 | >0.040 |

| >50 | >245 | ||||||

PVC Coated Copper Pipes in UK :- Applications

PVC Coated Copper Pipes are essential in multiple segments in the United Kingdom. They have many uses ranging from use in industries to general use since they are durable. They include such applications as in HVAC systems, oil and gas industries as well as residential plumbing among other applications.

Industrial Applications

- HVAC Systems : Facilitates efficient heat transfer and insulation relevant for both cooling and heating systems including those of commercial structures.

- Oil and Gas : Suitable for conveying both gases and liquid because of their processing capability and durability in various conditions.

- Refrigeration Systems : Learn how to regulate temperatures in cases of refrigeration and cooling to check energy wastage where needed.

- Power Plants : Employed in the circulated cooling water and thermal oil circulation system and heat transfer work in energy producing sections to maintain the operational efficiency.

- Chemical Processing : Protects against chemical reactions and is therefore suitable for the movement of fluids in various industrial operations.

General Applications

- Residential Plumbing : Provides safe water supply free from corrosion risks and with longer product durability.

- Fire Safety Systems : Relevant for sprinkler system as they are long lasting and very specific for application where high pressure is usually encountered.

- Solar Energy Systems : Promotes efficient transfer of heat in solar thermal systems to facilitate the best use of energy.

- Heating Systems : Applied in the central heating systems with high thermos stability, and with a good performance of energy conversion rates.

- Building Maintenance : Suitable for drainage, waste water system, and utility work in both residential and commercial buildings.

PVC Coated Copper Pipes in UK :- Advantages

- Increased durability owing to improved resistance to corrosion.

- Applicable in various industries and could also be used in general business.

- Better shielding from environmental contaminants such as ultraviolet radiation and dampness.

- It can be easily installed with choices of soft and hard PVC coverings.

- An effective solution that provides savings in terms of its maintenance.

- Environmental friendly product and can be recycled.