Table of Contents

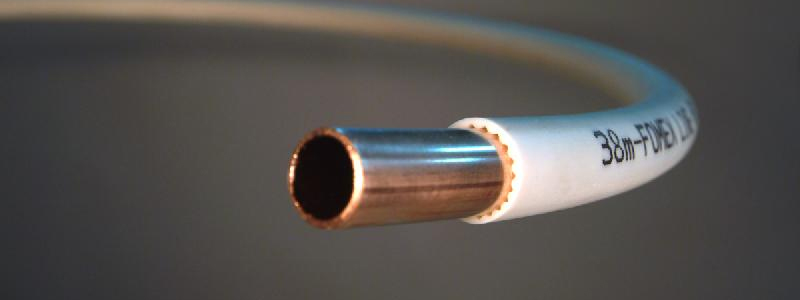

C-Fit Copper in India specializes in the manufacturing and export of PVC coated copper pipes and tubes to meet the increasing demand in markets such as Qatar. These high quality products offer superior anticorrosive protection with consistent durability necessary for the industrial and commercial uses. C-Fit Copper strive for innovation and customer satisfaction as C-Fit PVC coated copper pipes and tubes are in compliance with international standards. Being already established in the Indian market, we are aspiring to increase our presence and provide our clients in Qatar and other countries with high-quality, dependable products. C-Fit Copper is the preferred choice for you because of the efficacy and efficiency that it offers.

PVC Coated Copper Pipes Types:

Soft PVC Coated Copper Tubes in Qatar

Soft PVC coated copper tubes have excellent chemical inertia, high corrosion resistance, and flexibility for use in plumbing systems, heating, ventilating, and cooling systems, and refrigeration. The PVC layer also contributes to the protection against abrasion and chemicals which makes the device more durable and effective.

Hard PVC Coated Copper Pipes in Qatar

Hard PVC coated copper tubes from C-Fit Copper, a leading supplier of such products in India. These tubes have been designed to withstand various harsh conditions and environments since they are highly resistant to corrosion and have the best structural characteristics for any application in industries where strength and durability are most important.

MGL PVC Coated Copper Tube in Qatar

MGL PVC coated copper tubes will come in handy for various solutions in Qatar. These high-quality tubes are equipped with a PVC layer which, among other things, increases corrosion protection and product durability. For plumbing or HVAC or industrial applications, MGL PVC coated copper tubes offer efficiency and assurance.

Features of PVC Coated Pipes:

The Copper Pipe, PVC coated with the top rated corrosion and chemical resistance is manufactured to offer extra durability making it possible to be used in different industrial applications. Due to their faciality of flowing the fluids smoothly they are light enough to be installed easily while saving on labor costs. Low-cost and low maintenance, PVC painted pipes are environmentally friendly, being among the recyclable materials. Their adaptability enables them to be used in both underground and outdoor locations, where they will give superior performance independently on the environment.

PVC Coated Copper Pipes Specification, Sizes, Grades:

| Standards | EN 13348 / BS EN 1057 / ASTM B819 / ASTM B88 |

| Size | 6mm to 108 mm |

| Length | 3 meter |

| Tensile Strength | 220 Mpa |

| P.V.C Thickness | 0.014”to 0.059” |

| Material | Pure Copper |

| Application | Medical Gas Handling |

PVC Coated Copper Pipes Chemical Composition:

| Copper Pipe (Incl. Silver) | 99.85% Min. |

| Phosphorus | 0.013 to 0.5% |

| Total Impurities | 0.06% Max. |

Mechanical Property Of PVC Coated Copper Pipes:

| Density | 8.89 g/cm3 |

| Melting Point | 1370 °C (2500 °F) |

| Tensile Strength | Psi – 1,15,000 , MPa – 790 |

| Yield Strength (0.2%Offset) | Psi – 52,000 , MPa – 355 |

| Elongation | 40 % |

PVC Coated Copper Pipes Physical Property:

Standard | Copper No. | Chemical Composition | Mechanical Properties | ||||

|---|---|---|---|---|---|---|---|

| CU% | P% | Temper | Tensile strength (Mpa) | Elongation(%) | Average Grain Size (mm) | ||

| ASTM B280/68 | C12200 | 99.9 | 0.015 to 0.040 | >60 | >205 | >40 | >0.040 |

| >50 | >245 | ||||||

PVC Coated Copper Pipes Weight Chart:

Habits of PVC Coated Copper Pipes weight chart from C-Fit Copper are helpful in choosing the proper size pipe in the easiest way. Our products meet the largest output capacity and durability in the industry.

| Type | Size d2 t2/ d1 t1 | O.D. of the tube d1/d2/d3 | Thickness of Insulator t1/t2/t3/t4 | Length | Material | Weight Pounds/feet |

|---|---|---|---|---|---|---|

| P2320 | 1/4-0.032 3/8-0.032 | 1.02-0.87-1.89 | 0.35-0.2 | 30ft ~100ft | 0 | 0.233 |

| P2330 | 1/4–0.032 1/2–0.032 | 1.30-0.87-2.17 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.286 |

| P2420 | 1/4-0.032 3/8-0.039 | 1.42-0.87-2.29 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.39 |

| P2520 | 1/4–0.032 5/8–0.032 | 1.42-1.02-2.44 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.44 |

| P3620 | 3/8–0.0329 3/4–0.039 | 1.54-1.02-2.56 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.569 |

| P4620 | 1/2–0.032 3/4-0.039 | 1.54 1.30 2.84 | 0.394-0.2 | 30ft ~ 100ft | 0 | 0.629 |

Advantages and Disadvantages

Advantages:

- Corrosion Resistance: Great resistance against erosion.

- Durability: Longer lifespan and material conservation through rendering replacements unnecessary.

- Chemical Resistance: Suitable for the vast array of fluids

- Smooth Surface: Reduces frictional forces to affect smooth fluid flow.

- Versatility: It can be implemented in diverse fields.

Disadvantages:

- Limited Temperature Range: Can’t operate well in high temperatures.

- Mechanical Strength: May have weaker strength compared to uncoated pipes.

- UV Degradation: Sensitive to the sun-caused degradation.

- Installation Challenges: It needs special handling and skills.

- Environmental Concerns: Possible of harmful chemical contamination.