Table of Contents

At C-Fit Copper Fitting Manufacturer we are glad that we are a leading copper flanges manufacturer, dealer and exporter of Bahrain. It is at Solar that our respected product lines are subjected to the highest standards of quality and reliability encompassed in the best practices in product durability and performance. Being exact in copper flange manufacturing for many years, we can be customers’ one-stop source for standard and special parts.

Copper Flanges Manufacturer, Dealer, and Exporter in Bahrain

Our large and expanding global network enables us to provide best quality copper flanges manufacturer while also developing sustainable relationships with our clients. Click here for information and how you can benefit from us and our passion towards making your project a great success. That is what it means to have Copper Flanges Manufacturer today.

Copper Flanges Manufacturer, Dealer, and Exporter in Bahrain : Types

Copper Weld Neck Flanges

These flanges have elongated neck with tapered shape which gives them adequate structural stability necessary for high pressure systems. In the neck region, less stress concentration is experienced since there is a smooth transition between the flange and the pipe.

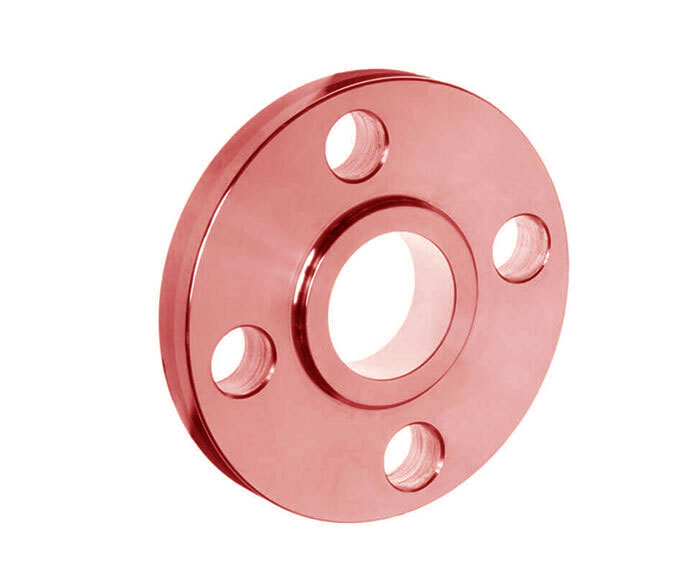

Copper Slip-on Flanges

These flanges fit over the pipe and are welded internally as well as externally for greater protection and security. These types are usually common in low pressure applications because of their applicability, convenience and cheap nature. They facilitate the pipe alignment and positioning during its installation or reparation with comparative ease.

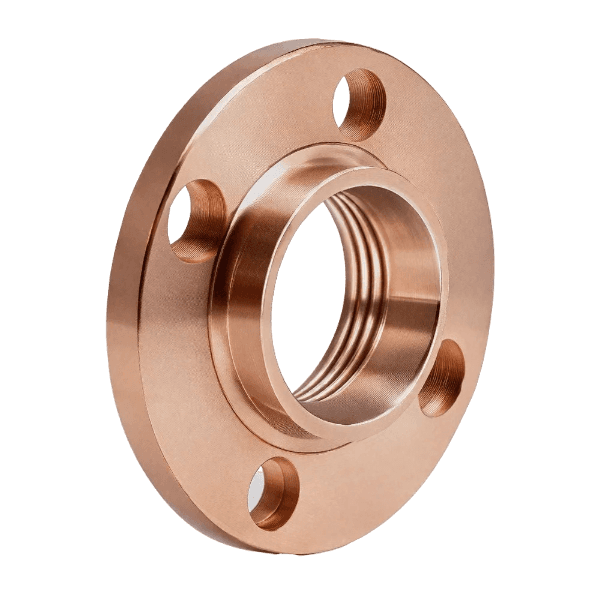

Copper Threaded Flanges

These flanges come with internal threads that enable them to be screwed on a pipeline thus making them useful in areas that welding cannot be applied. They are particularly useful in programmers where disassembly is frequently necessary, offering a secure connection without the need for welding.

Copper Blind Flanges

Being sealing accessories meant to seal the extremity of piping system, blind flanges are paramount in maintenance and inspection. They stop the passage of fluids or gases whenever the extremity of a pipe requires to be closed either temporarily or permanently. They are available in various sizes depending on the size of the respective pipe.

Copper Socket Weld Flange

These flanges are suited for pipe the systems with low diameters but high pressures. The pipe is fitted in the flange and in general the connection is made by welding since it offers high degree of pressure. These fibers are normally selected for their durability and their capacity to withstand harsh environments.

Copper Lap Joint Flanges

These flanges are for use with a lap joint stub end and are generally used in applications where the system might have to be disassembled and reassembled often. They can be easily aligned and adjusted; hence, they are suitable in areas of frequent maintenance or changes.

Use of Copper Flanges Manufacturer in Bahrain: Industrial and General Applications

Copper Flanges Manufacturer in Bahrain : Industrial Applications

- Chemical Processing Equipment:

Copper flange has found essential application in chemical processing because of the ability of the material to withstand the effects of corrosive chemicals and high temperatures. They also keep safe and steady contacts in pipelines and reactors. - Power Generation Systems:

Copper flanges are utilized in power plants and they are able to resist high pressure and enable energy transition. They provide the necessary long-term endurance to boilers, turbines, as well as other important equipment’s. - HVAC Systems:

In the industrial HVAC systems, the use of copper flanges is normally used to join piping and ductwork. Due to the nature of their thermal conductivity and strength, accommodated temperature control is evenly maintained complemented by the stability of the system. - Petrochemical Industry:

Copper flanges are applied at the petrochemical enterprises for regulating the hydrocarbons and other fluids. They withstand high chemical concentrations hence guarantee durability and safety. - Pharmaceutical Manufacturing:

In the manufacture of pharmaceutical products, copper flanges are applied in machineries that should be clean and should offer the best performance. it offers dependable service support in systems dealing with the extreme chemicals. - Energy Sector:

Copper flanges have the relevance in various systems such as the energy systems including the renewable energy systems. These are used in the supporting structure of wind mill and turbines, solar panels and other equipment for generating energy.

Copper Flanges Manufacturer in Bahrain : General Applications

- Residential and Commercial Plumbing:

Copper flanges are quite popular in the plumbing systems that are used in supply of water as well as in the draining systems. These characteristics make them have a long life cycle and durability on the application of water systems in residential and business premises. - Marine and Offshore:

Copper flanges are used in marine environments including the construction of vessels and offshore oil platforms due to its’ ability to withstand corrosives effects of sea water. They possess structural capacity that makes them remain rigid especially in tough marine climates. - Electronics and Electrical Systems: Copper flanges are used in electrical systems used in power distribution and electrical earthing systems. They provide perfect electrical connectivity due to their good conductivity hence providing safe connection to circuits.

- Heat Exchange Systems:

In heat exchangers and cooling systems, it is possible to control efficiently heat exchange by using copper flanges. In this way, the high value of their thermal conductivity positively affects the augment of heat transfer operations. - HVAC Systems:

Other than the industrial usage, copper flanges are also used in residential as well as commercial HVAC systems. These are used to join different parts which ensure that the system and all its subsystems remain effective and functional. - Automotive Applications:

Copper flanges are also used in automotive system for cooling and for the transfers of fluids. Due to their high strength and heat stability they may be used in car parts that are under high temperatures.