Table of Contents

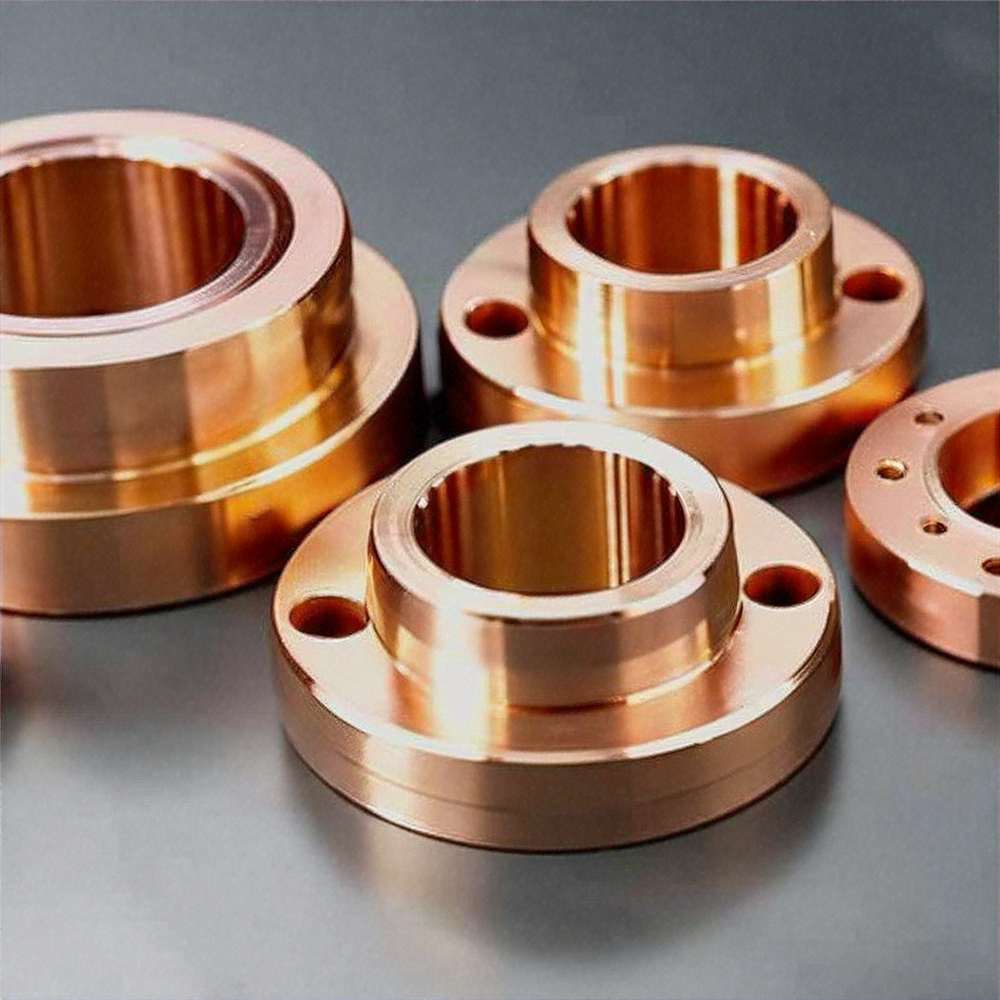

C-Fit Fitting Manufacturer Coppers is proud to be a supplier of the best copper flanges manufacturer in Doha. We put in our best to ensure every flange that we manufacture, deal or export is a reflection of this policy. By doing our work right for years and thus building a name for our-self we have become an identified brand in this field. Copper flanges for industrial or commercial use; our copper products line is fully stocked with high-quality and well-functioning flanges. See and feel for yourself how professional work and professional service can regalement differentiate themselves. In Doha, many satisfied customers have enjoyed our services in their provision of copper flange.

Copper Flanges Manufacturer, Dealer, and Exporter in Doha : Types

Copper flanges are one of the widely used products in piping systems in order to ensure a tight leak-proof joints between pipes, valves and other accessories. These flanges are varied and they are used according to the specified pressure, temperature and the kind of fluid that is to be transported. Below is a comprehensive guide to the various types of copper flanges: Below is a comprehensive guide to the various types of copper flanges.

Copper Weld Neck Flanges

Weld Neck Flanges are recognized by the long tapered hub that offers some support to the transition. These flanges are welded to the pipe at their neck, hence it becomes easier to produce straight flanges and there are little or no stress concentration at the base of the flange. These characteristics make them ideal for applications that require components to work under high pressure and high temperatures and that must be resistant to failure by fatigue.

Copper Slip-On Flanges

The principle of construction of slip-on flanges is convenient since they are installed by sliding over the pipe then welded. In order to obtain the connection, both the inside and outside of the flange needs to have fillet welds. Compared to weld neck flanges, slip-on flanges have less strength, but they are one of the cheaper options and are used for applications which include frequent assembly and disassembly of the flanges.

Copper Socket Weld Flanges

Socket weld flanges are utilized in conditions where pipe diameters are small but pressure is relatively the high. The pipe is placed within a pocket on the flange; one fillet weld is used on the periphery of the flange. This form of connection has no seam or any kind of obstacle to the flow of liquid which makes socket weld flanges suitable for stress applications.

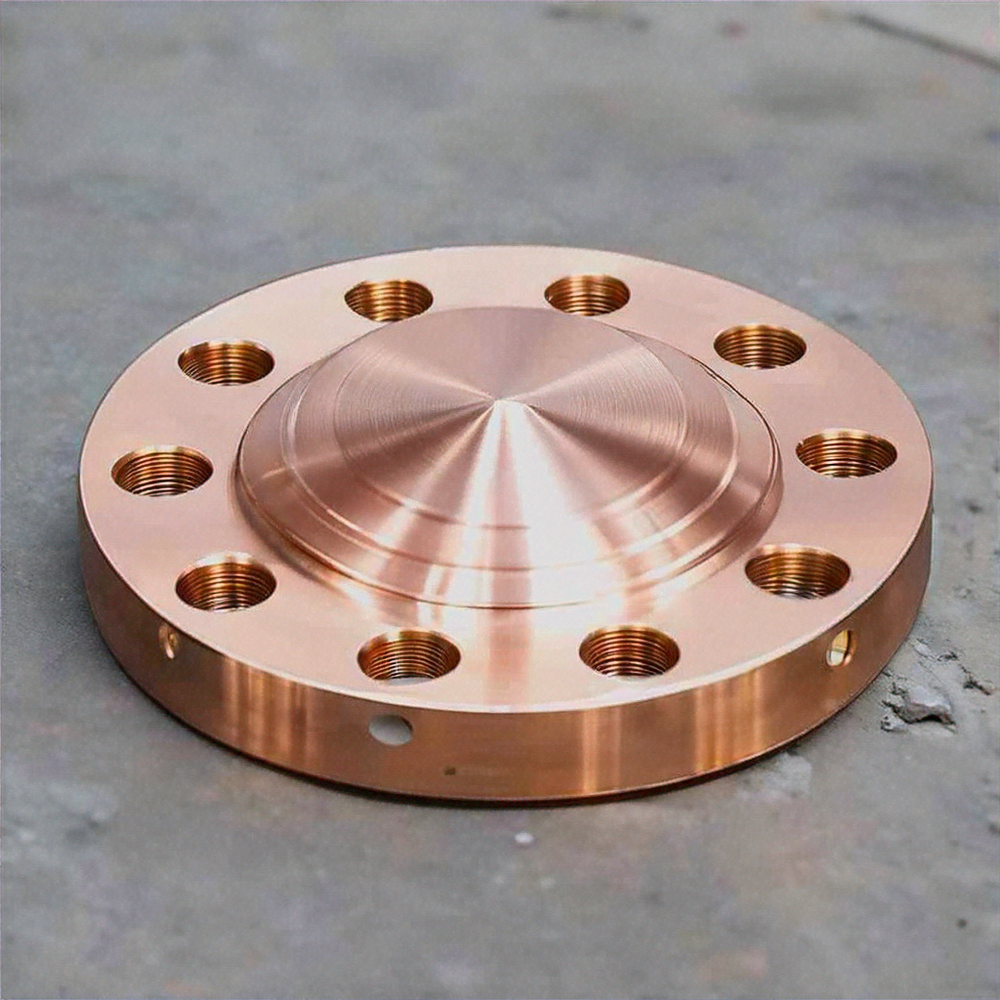

Copper Blind Flanges

Blind flanges are most commonly employed in the sealing of the ends of a piping arrangement or in the closing of an opening in a pressure vessel. They are indispensable where application involves constant checks or service as parts fitted with them can easily be unbolted and remounted. It is important to note that blind flanges are manufactured to endure pressure and can be manufactured from many materials in several sizes.

Threaded Flanges

Screwed flanges or threaded flanges are of those flanges in which internal threading correspond to the external threading of the pipe. This makes it easy when assembling without making the use of a welder to join the various parts together. This type of flanges acts appropriately for any system on which welding might be dangerous such as, in hazardous areas like flammable or explosive areas. They are typically applied in low pressure systems.

Lap Joint Flanges

Lap joint flanges are used in conjunction with a stub end; in fact, in a lap joint flange, the flange does not weld directly to the pipe. In this way the flange can rotate around the stub end thus making it easier to align and assemble the pipes. That is why lap joint flanges are quite useful where the piping system has to be dismantled often or where inspection is easy. It is normally used in applications which are not very critical or where pressure requirements are not very stringent.

For this reason, it is important that some knowledge be gained as to the various types of flanges made of copper so that they may be adequately chosen for a piping system. All kinds of copper flanges manufacturer have their own benefits like weld neck flanges have high strength to carry high pressure while slip-on flanges are very easy to install. Copper Fitting Manufacturer has various types of copper flanges that can suit various needs of the client where quality, durability, and reliability are guaranteed.

Use of Copper Flanges Manufacturer in Doha: Industrial and General Applications

Copper flanges from Copper Fitting Manufacturer are critical to performance across multiple uses across the USA, specifically Doha.

Industrial Applications

- Oil and Gas Industry: We hope that you find these fitting indispensable for joining high-pressure pipelines and other equipment.

- HVAC Systems: Facilitates the making of effective and tight joints in the heating and cooling systems.

- Chemical Processing: Does not corrode easily and thus helps in maintaining the system structures in event of contact with aggressive chemicals.

- Desalination Plants: Fends off corrosive saltwater therefore capable to withstand hard conditions.

- Power Generation: Helps to produce a high degree of heat exchange in steam and cooling systems.

General Applications

- Residential Plumbing: Used in making water supply lines since it offers long-term leak free joints.

- Fire Protection Systems: It facilitates reliable connection in sprinkler system for purposes of emergencies.

- Irrigation Systems: Used as connectors of pipes in agricultural systems and is able to endure changing climatic conditions.

- Air Conditioning Units: Improves conductivity in cooling systems to increase efficiency level.

- Automotive Repairs: Applied in the exhaust systems and coolant lines for heat safe conductors.

Copper Flanges Manufacturer, Dealer, and Exporter in Doha