Table of Contents

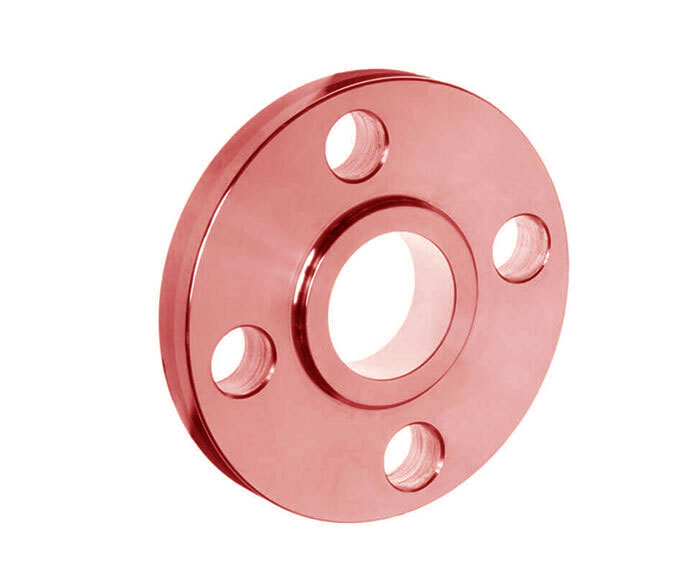

This is Copper Flanges Manufacturer, the leading manufacturer of copper flanges in Dubai. With that kind of experience in the field, we stand to have excellent products to suit clientele’s’ high standards in their projects. These products in construction, plumbing or any industrial related field are meant to perform to the expected levels of reliability. In this article, we are going to discuss about the available types of copper flanges, the fields they are perfect for and why you should work with us. Welcome to the website on Copper Flanges; let us explore the variety as well as the ideal products.

Copper Flanges Manufacturer, Dealer, and Exporter in Dubai : Manufacturer

Copper flanges Manufacturer are available in a number of types with each type specific to certain applications and standards. Starting with the slip-on flanges that are highly appreciated for their installation process up to the weld neck flanges designed for strong connections in high pressure applications, every need is met by pipes. It is crucial for a copper flange buyer to have the knowledge of the various copper flanges in the market so that they may be in a position to see to it that they select the most appropriate flanges for their projects to help them achieve efficiency and reliability in their projects.

Copper Slip-On Flanges

Types of slip-on flanges are able to be slipped over the end of the pipe. It is relatively easy to fit them and they are normally applied where pressure is low. Because of these they are widely used in the different piping systems.

Copper Weld Neck Flanges

The weld neck flanges have a long tapered hub which connects it well with the pipe. They are suitable for high pressure services and are normally applied in crucial operations.

Copper Blind Flanges

Blind flanges are forged, solid, and non-vented that is used at the extremity of a pipeline. They are crucial in withering pressure and thus control the flow of fluids in a system.

Copper Socket Weld Flanges

Socket weld flanges are shaped to rest in the flange’s respective socket; this leads to a proper welding being made. These are used in most pressure and temperature conditions which include high pressure and temperature.

Copper Threaded Flanges

Threaded flanges come with internal threads which enable them to be screwed in the pipe. They are suitable where welding cannot be used and hence the installation is very easy and can be completed within a short duration.

Copper Lap Joint Flanges

Lap joint flanges fit with a matching Stub End thus making them easier to align and assemble. They are best suited to use in activities where components are frequently taken apart and reassembled.

Copper Flanges Manufacturer, Supplier and Exporter in Dubai : Dimension and Weight Table

| Nominal Size | Outside Diameter | Min. Thickness | RF Dia. | No. of Bolt Holes | Diameter of Holes | Bolt Circle | SO Bore ID | WN Bore ID | Dia. Hub Base | Dia. of Hub Top | SO LTH | WN LTH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (OD) | (T) | (R) | (BC) | (SB) | (WB) | (HB) | (HT) | (SL) | (WL) | |||

| 1⁄2 | 3.5 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.5 | 1.05 | 0.56 | 2 |

| 1 | 4.25 | 0.5 | 2 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.5 | 4 | 0.62 | 3.5 | 1.7 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.9 | 0.81 | 2.38 |

| 2 | 6 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7 | 0.81 | 4.12 | 4 | 0.75 | 5.5 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.5 | 0.88 | 5 | 4 | 0.75 | 6 | 3.57 | 3.07 | 4.25 | 3.5 | 1.12 | 2.69 |

| 31⁄2 | 8.5 | 0.88 | 5.5 | 8 | 0.75 | 7 | 4.07 | 3.55 | 4.81 | 4 | 1.19 | 2.75 |

| 4 | 9 | 0.88 | 6.19 | 8 | 0.75 | 7.5 | 4.57 | 4.03 | 5.31 | 4.5 | 1.25 | 2.94 |

| 5 | 10 | 0.88 | 7.31 | 8 | 0.88 | 8.5 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11 | 0.94 | 8.5 | 8 | 0.88 | 9.5 | 6.72 | 6.07 | 7.56 | 6.63 | 1.5 | 3.44 |

| 8 | 13.5 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16 | 1.12 | 12.75 | 12 | 1 | 14.25 | 10.88 | 10.02 | 12 | 10.75 | 1.88 | 3.94 |

| 12 | 19 | 1.19 | 15 | 12 | 1 | 17 | 12.88 | 12 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14 | 2.19 | 4.94 |

| 16 | 23.5 | 1.38 | 18.5 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18 | 16 | 2.44 | 4.94 |

| 18 | 25 | 1.5 | 21 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18 | 2.62 | 5.44 |

| 20 | 27.5 | 1.62 | 23 | 20 | 1.25 | 25 | 20.2 | 19.25 | 22 | 20 | 2.81 | 5.62 |

| 22 | 29.5 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22 | 3.07 | 5.82 |

| 24 | 32 | 1.81 | 27.25 | 20 | 1.38 | 29.5 | 24.25 | 23.25 | 26.12 | 24 | 3.19 | 5.94 |

Use of Copper Flanges : Special Applications and General Uses

Industrial Applications

- Plumbing Systems: Metallic copper flanges Manufacturer are mostly preferred in the plumbing of water and other fluids due to the fact they help to fix pipes together, making the whole system compact and leakage free.

- HVAC Systems: Its applications include usage in heating, ventilating as well as air conditioning systems to control the flow and performance.

- Chemical Processing: Copper flanges are quite durable when it comes to corrosion and any form of aggressive chemicals thus making it applicable in a variety of chemical processes.

- Oil and Gas Industry: They use it in their pipelines as well as in refineries due to their endurance of high pressure as well as high temperature.

General Applications:

- Residential Use: Copper flanges Manufacturer are normally used for joining fixtures in residential plumbing ranging from sinks and faucets among others.

- Art and Decor: They can also be applied in artistic configuration forming part of sculpture and interior designs.

- Automotive Industry: Copper flanges are used in types of engine parts and cooling systems because copper has the best property of heat conductivity.

- Marine Applications: Due to the fact that most of them have a non-corrosive nature especially in contact with salt water, they are frequently used in boats and other marine equipment.