Table of Contents

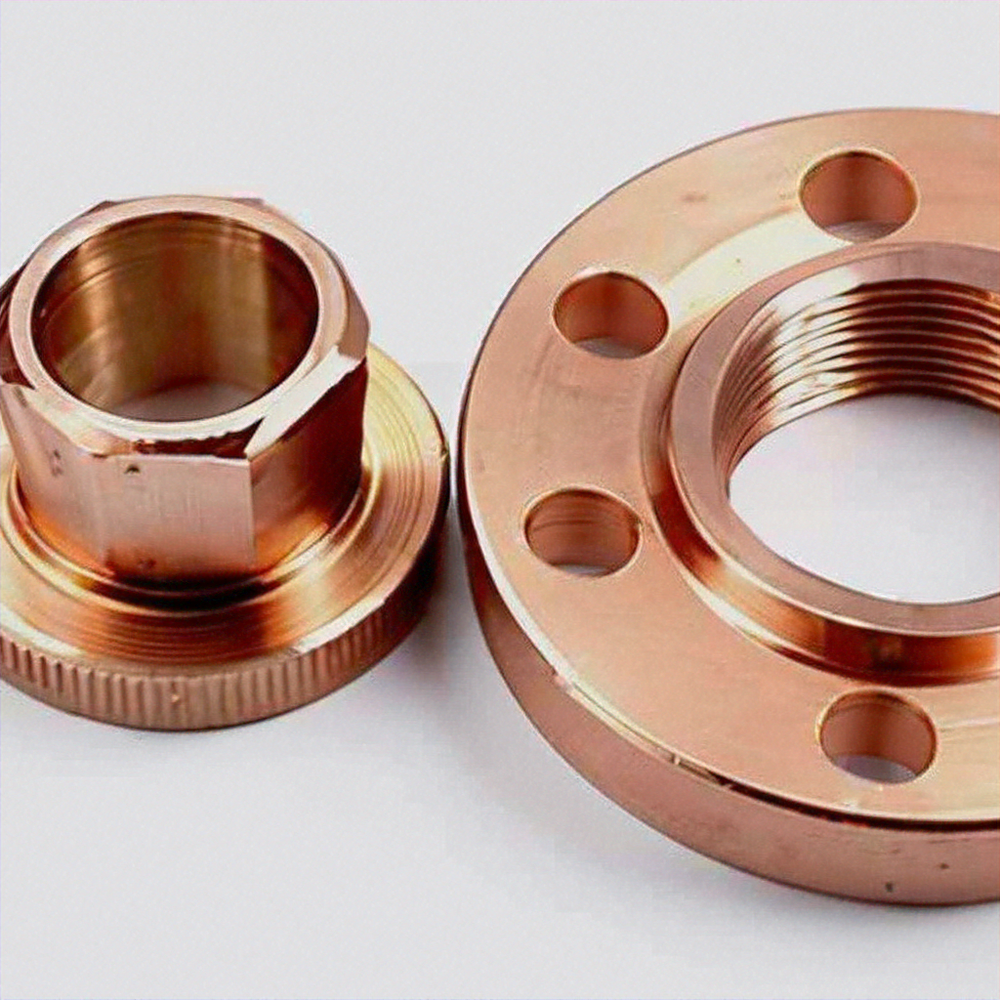

Copper Fitting Manufacturer has a very rich experience in the manufacture of copper flanges manufacturer in Kuwait. Being one of the leading manufacturers, dealers, and exporters we maintain quality as the major priority and ensure that all products are of superior quality. This more than 50 years of experience coupled with the high level of commitment delivers a flange for copper that is durable and efficient.

Copper Flanges Manufacturer, Dealer, and Exporter in Kuwait

If you require copper flange or any other types of copper flanges for your industrial requirement or any special projects, then our team would be happy to assist you and provide you best service and solutions as per your requirement. Find the reason behind choosing us for acquiring copper flanges in Kuwait and taste the best service and quality.

Copper Flanges Manufacturer, Dealer, and Exporter in Kuwait : Types

Copper flanges manufacturer are an integral accessory of pipe and equipment and are particularly noted for their strength, non-corroding nature, heat and electrical conductivity. Here’s a look at the most common types of copper flanges used in various applications : Here’s a look at the most common types of copper flanges used in various applications:

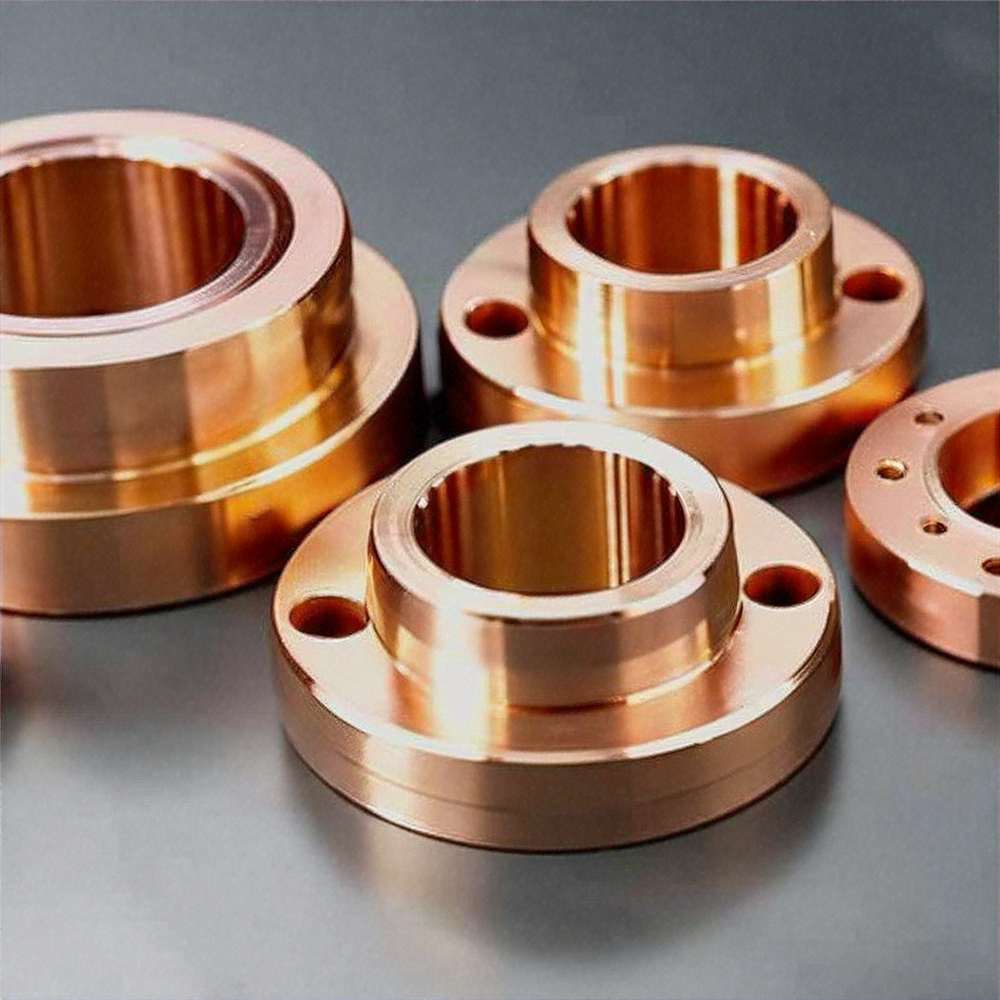

Copper Weld Neck Flanges

Long neck flanges can also be present in this type of weld neck flanges since they are welded to the pipe so as to give a seamless transition from the pipe to the flange. This type is suitable when the pressure is high and it the best as regards strength and stresses withstand.

Copper Slip-On Flange

These flanges have been designed in a way that they can be slipped to the end of a pipe so as to ease the alignment and welding process. These are generally applied where the other flange has a lower cost, but the connection made is nonetheless quite strong and secure.

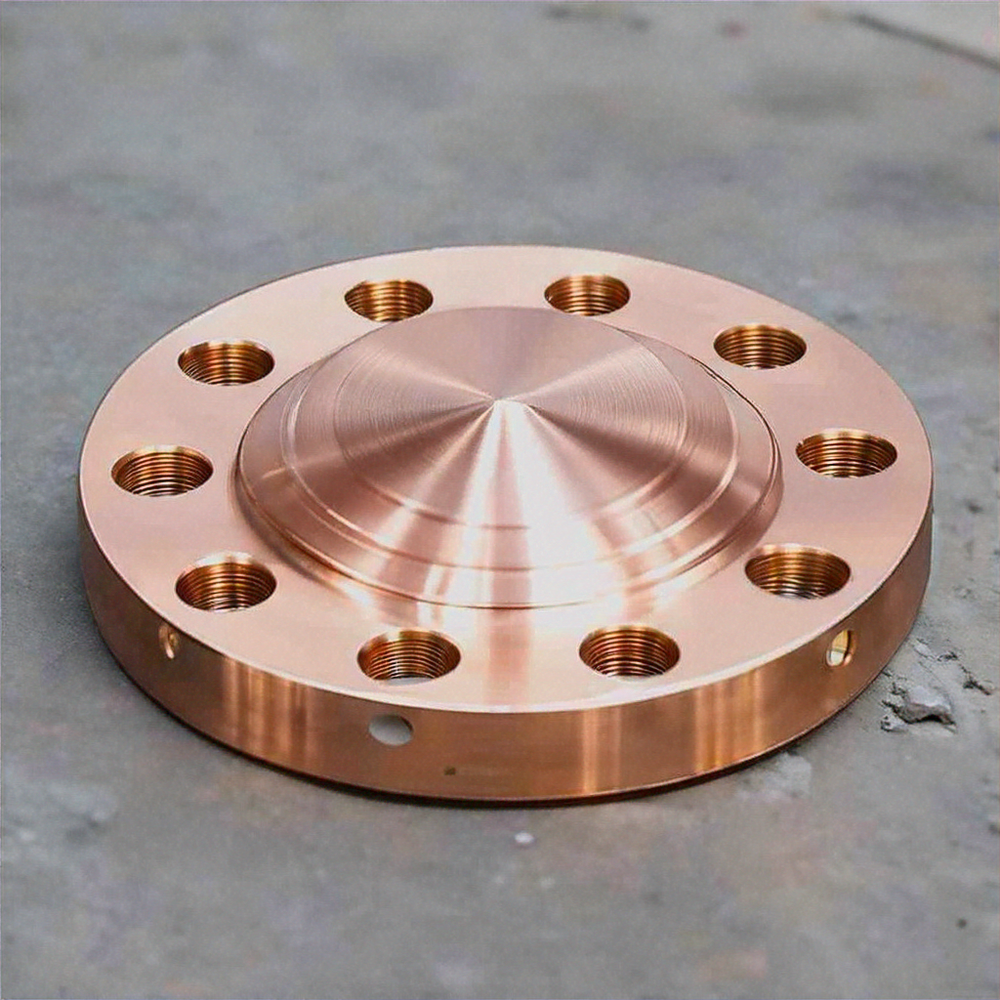

Copper Blind Flanges

Blind flanges are usually employed on the end of a piping system so as to shut a segment. They are also significant in the cases such as maintenance an inspection when the access to the system is required.

Copper Socket Weld Flanges

For pipes of comparatively smaller diameter, the socket weld flange is used where the pipe is positioned into the flange and welded at the edges of the joint. They deliver firm connection and are useful in application such as high pressure and higher temperature application.

Copper Threaded Flanges

These flanges have internal screw threads that enable them to be screwed on a pipe having outer screw threads. They are ideal for use in systems that undergo frequent disassembly and reassembly whereas they are not ideal for high pressure systems.

Copper Lap Joint Flanges

When coupled with a lap joint stub end, these flanges are most suitable for use where disassembly is frequently needed. They afford freedom and are applied in systems where it is easy to dismantle to access and clean or repair.

Different copper flange manufacturer has its own use depending on the needs of the pipe system that is going to be used. It plays an important role deciding the efficiency and durability of the flange, thus different factors like operating pressure, temperature, and ease to clean etc. should be considered before selecting the correct type of flange.

Use of Copper Flanges Manufacturer in Kuwait: Industrial and General Applications

Industrial Use of Copper Flanges

- Oil and Gas Industry: Copper flanges find applications in the oil and gas industry in Kuwait thanks to their highly resistant nature to corrosion as well as high temperature. These are crucial in joining pipes and equipment in different operations such as drilling, extraction and pipe work.

- Chemical Processing: As we know, in chemical plants, copper flanges are more durable and can resist different types of chemicals and high pressure in the plants. They are applied to guarantee that there is no leakage of connections in the processing systems.

- Power Generation: Copper flanges are found important in power generation plant in order to join pipes and parts of the cooling system, steam turbine, and other structures. That way, they guarantee the proper transfer of heat and provide high efficiency of the system.

- Water Treatment: Copper flanges are also used in water treatment plants because copper is an antimicrobial material and is also capable of withstanding corrosion. They are used in pipelines and in fittings for the transportation and effective handling of treated water.

General Use Of Copper Flanges

- HVAC Systems: Flanges in HVAC systems can be copper used in joining of many parts including the ducts and pipes that are in the system. Thermal conductivity of these materials is useful in determining system efficiency and its performance.

- Residential Plumbing: Residential copper flanges are used and trusted for their durability and flexibility since they are easy to install. They are applied in joining pipes and fixtures for waters supply and drainage systems making them sturdy and secure.

- Food and Beverage Industry: The food and beverage industry in Kuwait uses copper flanges because of the latter’s non-porous surface and non-stick nature which does not allow contamination. They are employed in equipment and subsequent pipe line that is required to transport food products which must be of high hygiene standards as well as safety assurance.

- Construction Projects: Copper flange is used in construction and engineering; the flange is commonly used in the construction of pipe work for buildings’ and structures’. Because of their durability and immaterial against corrosion it can be used both inside and outside the buildings.