Table of Contents

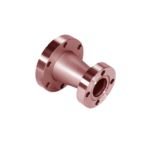

Copper pipes have been in use for many years and are preferred in plumbing systems because of their efficiency, durability, and ability to fit many different applications. Copper pipes have been used extensively for a long time and are still well-known for being the foundation of many plumbing systems installed in homes, businesses, and factories. These copper pipes are suitable for internal and external plumbing and they provide pure drinking water and proper drainage systems.

Copper Pipes can also resist high temperatures and pressures, therefore they are used for hot water distribution, heating, ventilating and air conditioning systems, and fire protection systems. Apart from their functionality, copper pipes are decorative objects that are lauded for their sustainability since copper is 100% recyclable. Therefore, these vans remain popular not only for their high performance but also for their nice design and, of course, the relative simplicity of installation. Copper pipes have been used by cultures from times past all the way up to contemporary construction projects due to its quality and durability in plumbing systems.

Types of Copper Pipes:

- Type M Copper Pipe: Type M copper pipe is the thinnest and can be purchased at a relatively low cost in comparison to the other copper pipe types. PVC is primarily employed in residential applications because it can become damaged when exposed to high amounts of pressure or temperature. It is also important to notice that this type of wire is divided into red color coded wires, which denotes the Type M wire.

- Type L Copper Pipe: This pipe is available in two types the type L which is thicker and more rigid than the type M and can be used in residential and commercial application. It endures higher pressures and temperatures as compared to rusted iron hence prefers when used in distributing hot water. This is an indication of the fact that type L is blue color coded.

- Type K Copper Pipe: Copper Type K pipe is the heaviest and mechanically most robust of the copper pipe types since it is destined for use in applications that are heavy duty and which have to support high degree of pressure. It is often applied in the industrial and business buildings, as well as in the construction of sub-structures. Type K is green coded.

Advantages of Copper Pipes:

- Excellent corrosion resistance

- Longevity exceeding 50 years

- High thermal conductivity

- Suitable for hot and cold water

- Environmentally friendly and recyclable

- Resistant to UV degradation

- Low maintenance requirements

- Can be soldered or brazed easily

- Compatible with various joining methods

- Reliable performance in diverse environments

Points to consider while choosing copper pipes:

To choose the best copper pipes for your project, consider the following six important points:To choose the best copper pipes for your project, consider the following six important points:

- Quality Assurance: Purchase copper pipes from well-established producers who specifically focus on materials of the best quality adopted to industry specifications. Certifications such as ASTM (American Society for Testing and Materials) or ANSI (American National Standards Institute) are what you should look for.

- Type Selection: Learn the exact demand of your plumbing system to decide on the sort of copper pipe that will provide service best (at example Type M, Type L, Type K). There are various considerations such as pressure ratings, temperature compatibility, and usage to consider while purchasing the equipment.

- Corrosion Resistance: Ensure that such pipes have the best corrosion properties that would enable them to last longer and work effectively in conditions that would otherwise lead to their corrosion such as in areas close to the sea or in areas with hard water conditions.

- Cost Consideration: Consider the cost of copper pipes on the initial investment and the importance of having the right pipes for the long term. It is in this context that higher quality of material costs more but is more economical to use in the long run given that fewer costs will be incurred in maintenance and replacement.

- Application Suitability: Identify and evaluate the various functions that the plumbing system should perform as well as the recommended usage of the system. Features like water temperature, pressure, as well as chemical compatibility should guide the choice of these copper pipes for the project at hand.

- Compliance Verification: Copper pipes should be sourced from a reputable supplier that meets manufacturing standards and government requirements. Check whether contractors and plumbers have complied with quality and safety standards to ensure that installed plumbing will be efficient and safe.

Copper Pipe Sizes With its Cost:

Copper C-Fit Bends are produced out of C12200 copper and their size can be between 6mm and 108mm and their thickness of wall between 0.5mm and 3mm. They are available as short and long radius fittings and pass the ASTM, EN12735 and JIS specifications of HVAC, refrigeration and plumbing fittings.

| Nominal Size (inches) | Nominal Dimensions (inches) | Outside Diameter (inches) | Inside Diameter (inches) | Wall Thickness (inches) | Price per Foot (₹) |

|---|---|---|---|---|---|

| 1/8 | A | 0.125 | 0.065 | 0.03 | ₹59.73 |

| 3/16 | A | 0.187 | 0.128 | 0.03 | ₹80.48 |

| 1/4 | A | 0.25 | 0.19 | 0.03 | ₹115.00 |

| 5/16 | A | 0.312 | 0.248 | 0.032 | ₹158.75 |

| 3/8 | A | 0.375 | 0.311 | 0.032 | ₹155.00 |

| 3/8 | D | 0.375 | 0.315 | 0.03 | ₹167.87 |

| 1/2 | A | 0.5 | 0.436 | 0.032 | ₹195.00 |

| 1/2 | D | 0.5 | 0.43 | 0.035 | ₹207.50 |

| 5/8 | A | 0.625 | 0.555 | 0.035 | ₹235.00 |

| 5/8 | D | 0.625 | 0.545 | 0.04 | ₹262.50 |

| 3/4 | A | 0.75 | 0.68 | 0.035 | ₹275.00 |

| 3/4 | A | 0.75 | 0.666 | 0.042 | ₹317.50 |

| 3/4 | D | 0.75 | 0.666 | 0.042 | ₹317.50 |

| 7/8 | A | 0.875 | 0.785 | 0.045 | ₹371.25 |

| 7/8 | D | 0.875 | 0.785 | 0.045 | ₹371.25 |

| 1 1/8 | A | 1.125 | 1.025 | 0.05 | ₹495.00 |

| 1 1/8 | D | 1.125 | 1.025 | 0.05 | ₹495.00 |

| 1 3/8 | A | 1.375 | 1.265 | 0.055 | ₹570.00 |

| 1 3/8 | D | 1.375 | 1.265 | 0.055 | ₹570.00 |

| 1 5/8 | A | 1.625 | 1.505 | 0.06 | ₹625.00 |

| 1 5/8 | D | 1.625 | 1.505 | 0.06 | ₹625.00 |

| 2 1/8 | D | 2.125 | 1.985 | 0.07 | ₹735.00 |

| 2 5/8 | D | 2.625 | 2.465 | 0.08 | ₹950.00 |

Applications of Copper Pipes

- Central AC Systems: Use them in large refrigeration plants for commercial and industrial cooling applications.

- Automotive AC: Cool air in vehicle cabin through transport refrigerant in vehicle air conditioning systems.

- Refrigeration Units: Preserve low temperatures in supermarkets, food processing plants and cold storages.

- Medical Equipment: Provide 99% relative humidity for critical cooling of medical facilities and laboratories and temperature sensitive processes.

- Transportation Cooling: For fresh produce and other perishable goods, it is important to make sure that they are stored at low temperatures during transportation in reefer vehicles and reefer containers.

- HVAC Systems: Help in circulation of refrigerant in the heating, ventilation, and air conditioning systems.

- Split AC Units: Join two systems inside and outside premise for optimal cooling of rooms and business facilities.

- Ductless Mini-Splits: There is a possibility to connect individual indoor units to the common outdoor unit in order to control the cooling in the zones.

- Specialized Cooling: Applied widely in industrial coolant and electronic cooling among others.

- Data Centers: Include the support of cooling systems for data centers and server rooms to avoid heat buildup.